Pneumatic down-the-hole hammer drilling device

A technology of drilling device and down-the-hole hammer, which is applied in the direction of driving device for drilling in borehole, earthwork drilling, drilling equipment, etc. It can solve the problems of affecting drilling efficiency and difficulty in slag discharge, so as to reduce the escape of slag, Ensure the effect of improving drilling efficiency and storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

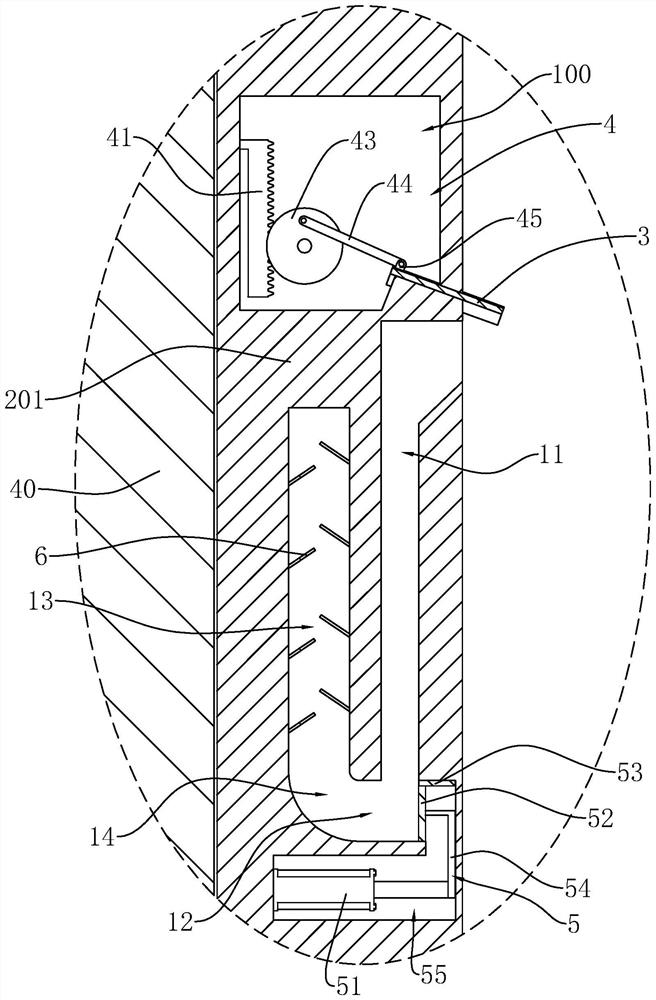

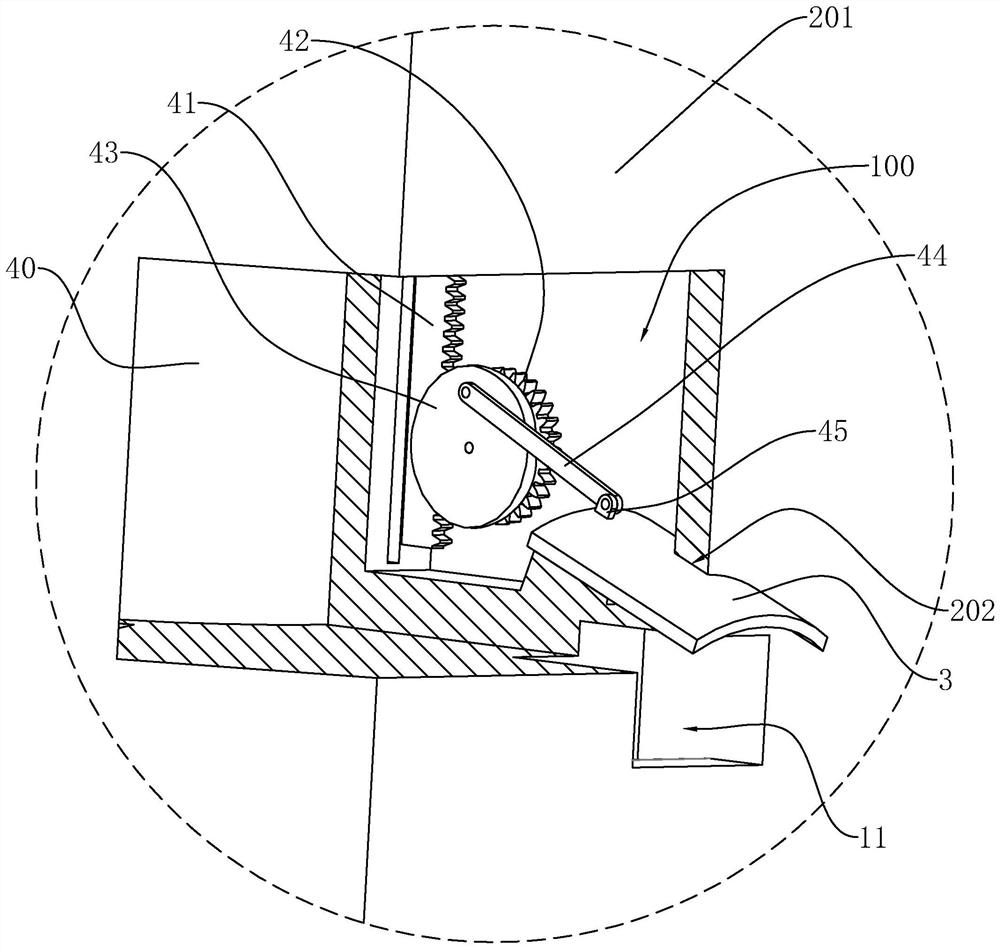

[0053] Embodiment 2, on the basis of embodiment 1, the following settings are made, as Figure 4 As shown, the casing 201 is also provided with an impeller 7 and a second driving mechanism 8 for driving the impeller 7 to rotate, wherein the impeller 7 is located at the entrance of the slag duct 11, and the second driving mechanism 8 is used for driving the impeller 7 to rotate. The direction of rotation of 7 is as Figure 4 shown.

[0054] like Figure 5 , Image 6 As shown, the impeller 7 includes a rotating shaft 71 and three blades 72 fixed on the outer surface of the rotating shaft 71. The rotating shaft 71 is horizontally perpendicular to the sliding direction of the guide plate 3. The two ends are respectively located in the third working chamber 300 opened by the casing 201 , and the hole between the third working chamber 300 and the slag inlet 11 is sealed by a sealing ring.

[0055] The second driving mechanism 8 may be a driving motor that drives the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com