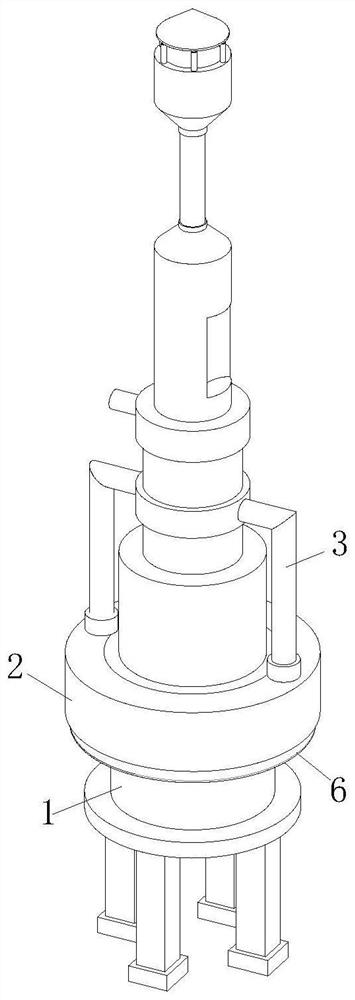

High-strength waterproof rock wool board preparation system

A preparation system and rock wool board technology are applied in the field of high-strength waterproof rock wool board preparation system, which can solve the problems of increasing the workload of operators and spraying, and achieve the effect of reducing labor burden and protecting life safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

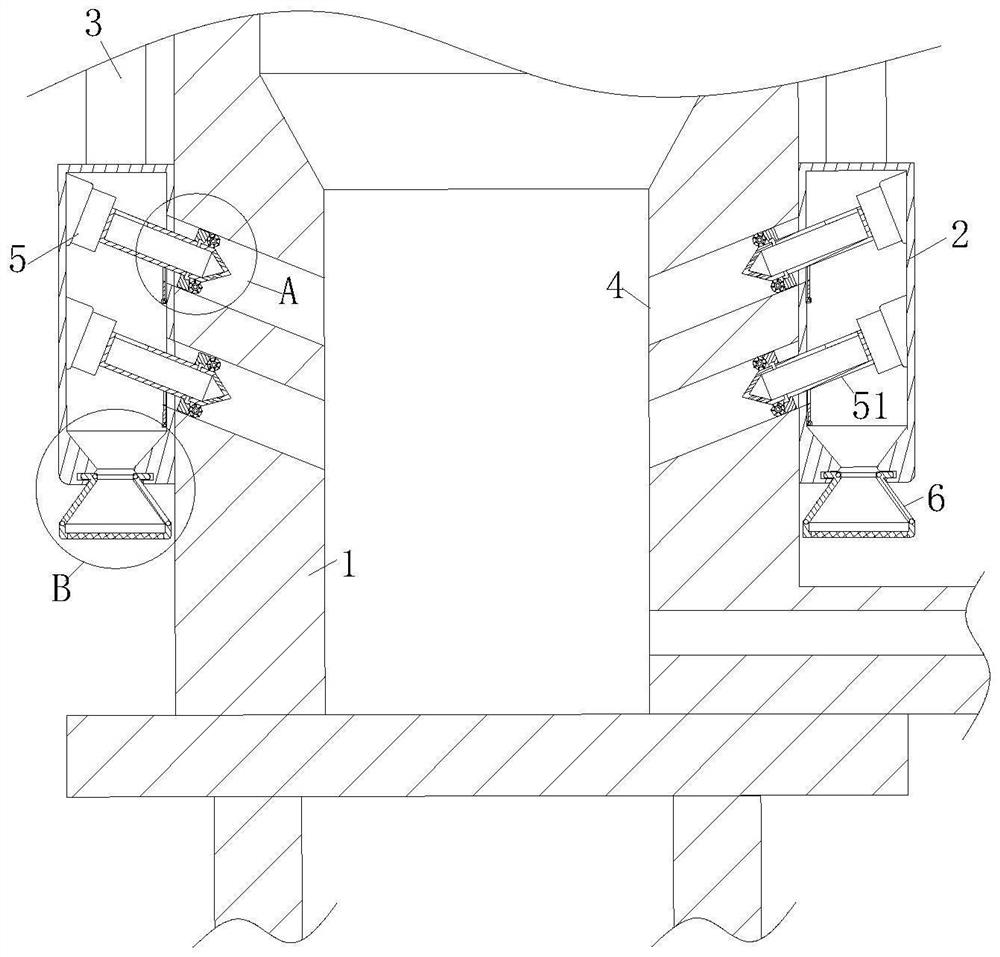

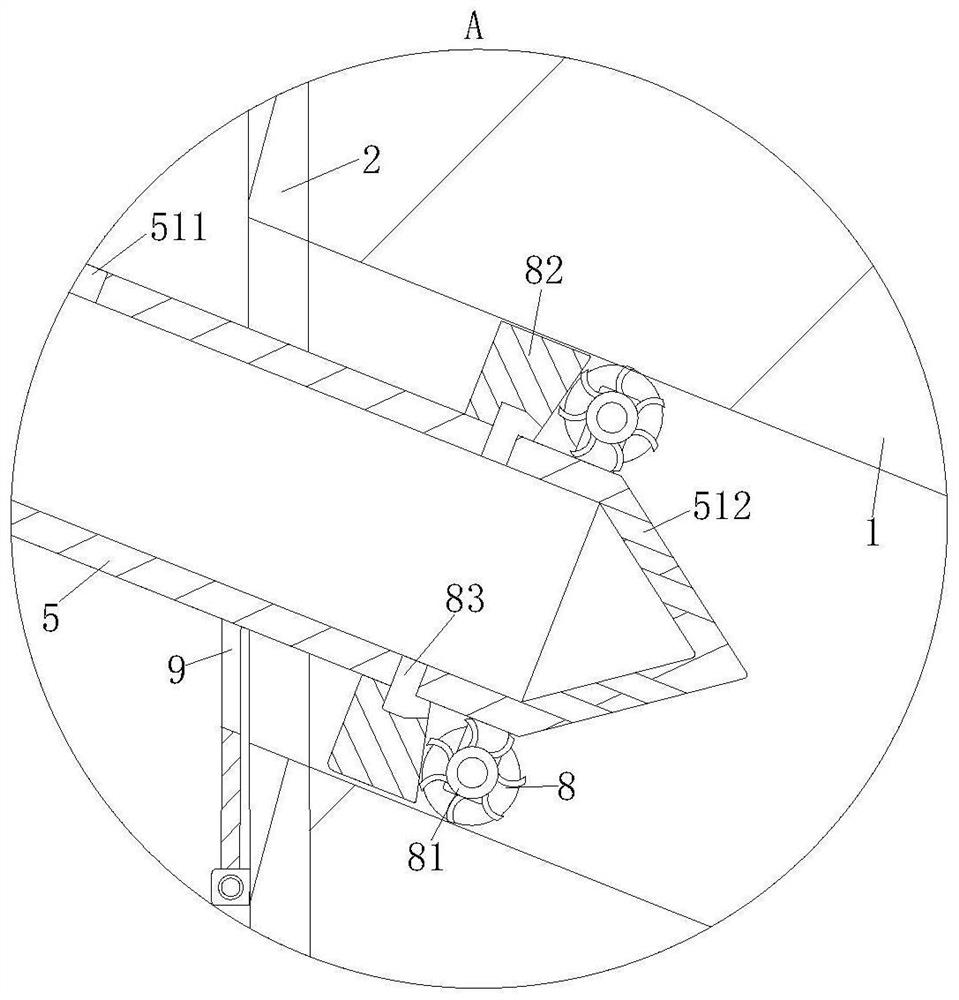

[0050] As an embodiment of the present invention, the top rod 51 is internally provided with:

[0051] No. 1 slot 511, the No. 1 slot 511 is opened on the upper surface of the ejector rod 51 to transport air to the inside of the ejector rod 51;

[0052] The No. 2 slot 512, the No. 2 slot 512 is evenly opened at the end of the ejector rod 51 away from the telescopic rod 5, so as to transport the air in the ejector rod 51 into the furnace body 1;

[0053] When working, the upper surface of the ejector rod 51 is provided with a No. 1 slot 511, and the end of the ejector rod 51 away from the telescopic rod 5 is evenly provided with a No. 2 slot 512. The controller controls the air pump to blow into the No. 1 ring 2 through the air supply pipe 3. Air, so that the air enters the inside of the ejector rod 51 through the No. 1 slot 511 and is sprayed into the tuyere channel 4 through the No. 2 slot 512, so that the air impacts the slag in the tuyere channel 4, and the air also pushes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com