Verification method and system for fuel dispenser

A fuel dispenser and fuel oil technology, which is applied to the record carrier used by the machine, data processing applications, computer components, etc., can solve the problems of cumbersome collection process, large error, and fluctuation of error rate, so as to avoid large error and low error Rate fluctuations, the effect of preventing cheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

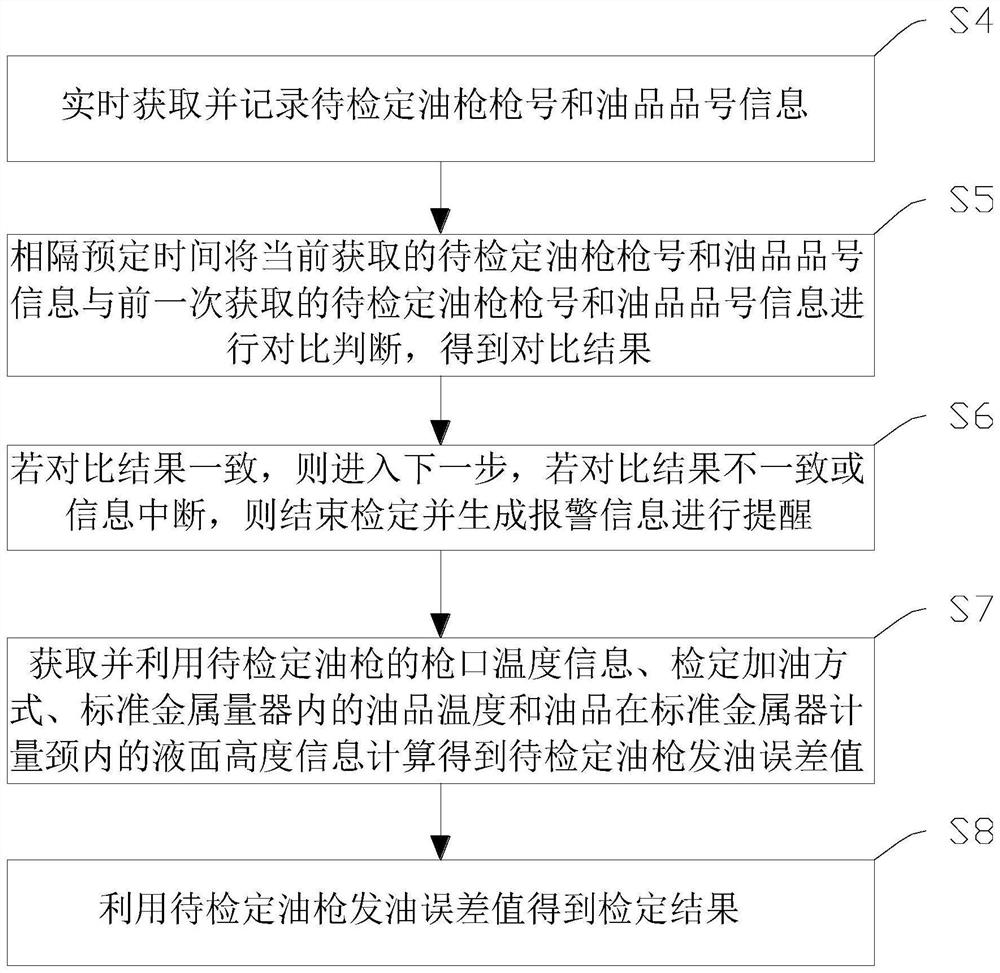

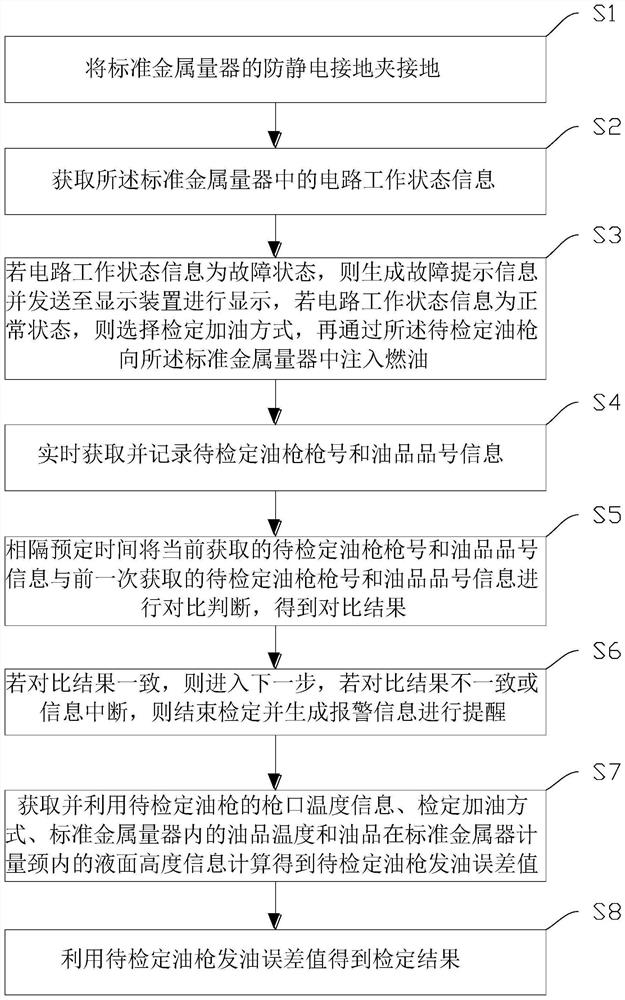

[0056] see figure 1 , the verification method for a fuel dispenser includes the following steps:

[0057] Step S4: Real-time acquisition and recording of the gun number and oil product number information of the oil gun to be verified.

[0058] In the above steps, by acquiring and recording the information of the gun number and the oil product number of the oil gun to be verified in real time, the original data can be provided for the subsequent judgment of whether the comparison verification object is correct.

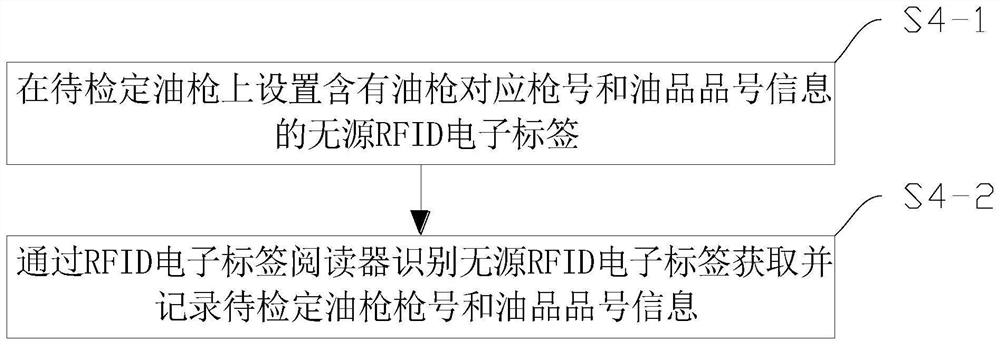

[0059] see figure 2 , the steps of obtaining and recording the information of the gun number and oil product number of the oil gun to be verified in real time include:

[0060] Step S4-1: A passive RFID electronic label containing information on the oil gun corresponding to the gun number and the oil product number is set on the oil gun to be verified.

[0061] In the above steps, the RFID tag is easy to set and small in size, and can be hidden on the oil gun witho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com