Method for calculating sensitivity of single-ring Rogowski coil current sensor with arbitrary skeleton shape

A technology of current sensors and Rogowski coils, which is applied in the direction of instruments, measuring electrical variables, and measuring devices, can solve the problems of complex 3D model process, long calculation cycle, and poor versatility, and achieve design time saving, convenient calculation, and easy calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

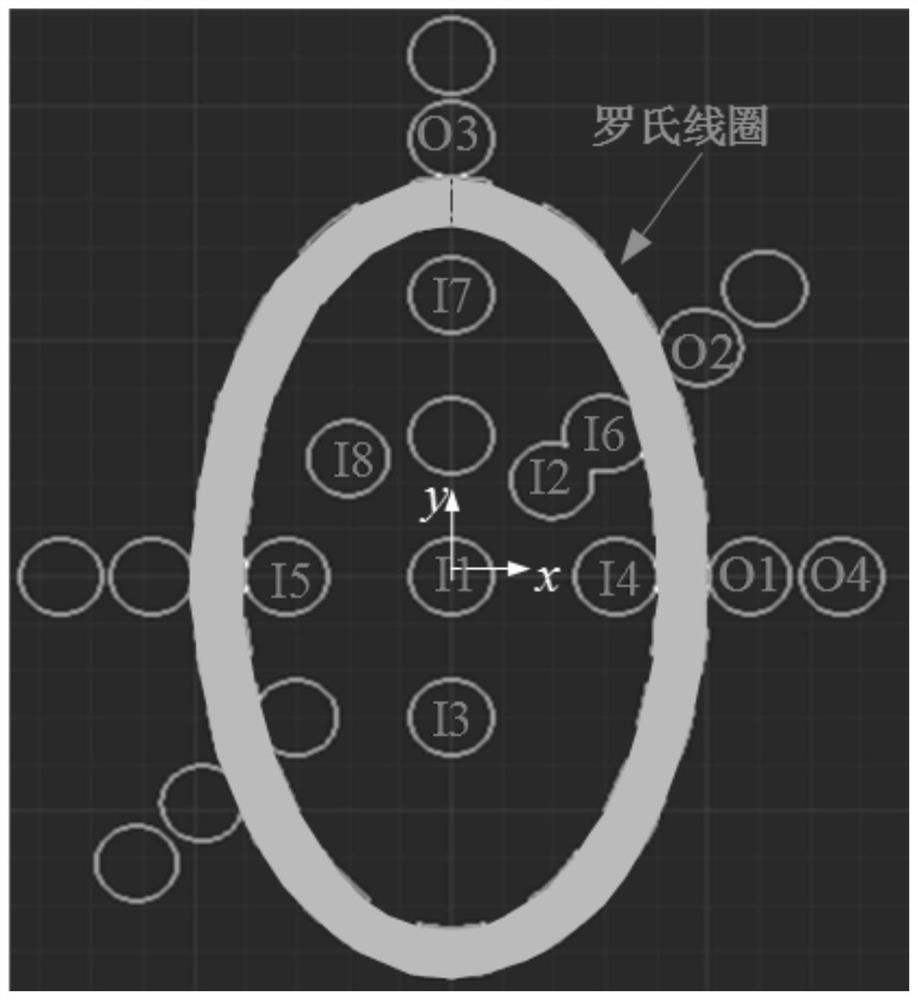

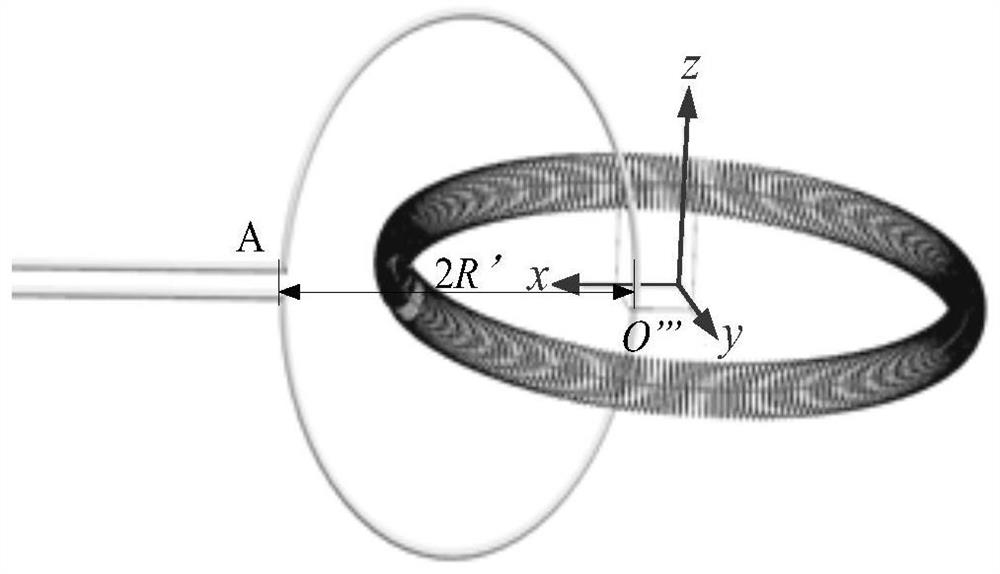

[0068] In the embodiment of the present invention, a common Rogowski coil with a circular skeleton and a circular cross-section is selected for description.

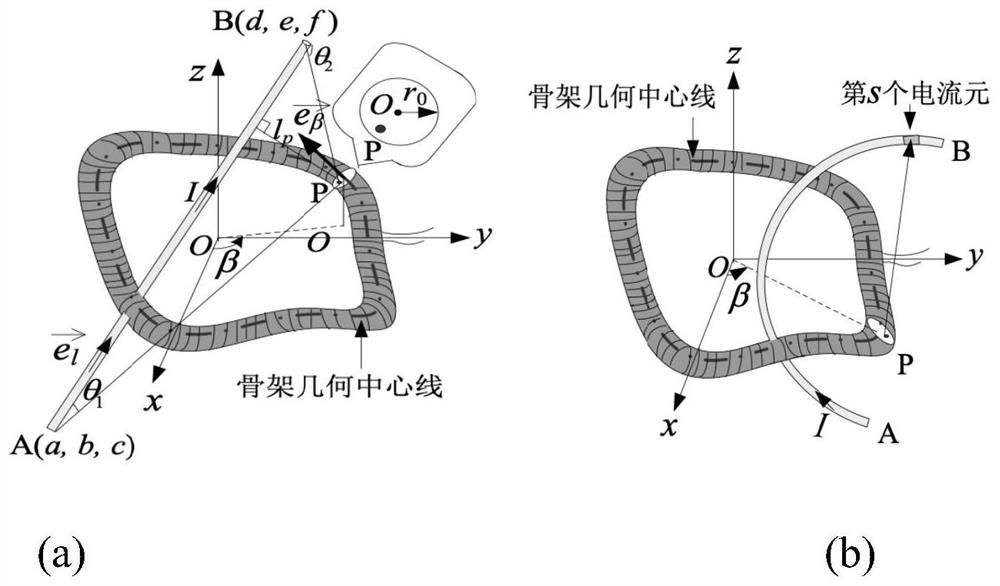

[0069] Step 1, such as figure 1 As shown, a three-dimensional Cartesian coordinate system is established with a point in the Rogowski coil as the coordinate origin. Write down the geometric centerline equation of the Rogowski coil. The geometric centerline also vertically passes through the geometric center of the turn section. The parametric equation of the centerline of the Rogowski coil bobbin is:

[0070]

[0071] In the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com