Movable spring assembly of relay and electromagnetic relay

A relay and moving spring technology, applied in the field of moving spring components and electromagnetic relays, can solve the problems of thermal stress and mechanical stress defects, large changes in action and release parameters, different deployment lengths and shapes, etc., to achieve mechanical stress and thermal stress. Small, consistent thermal expansion coefficient, stable release parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

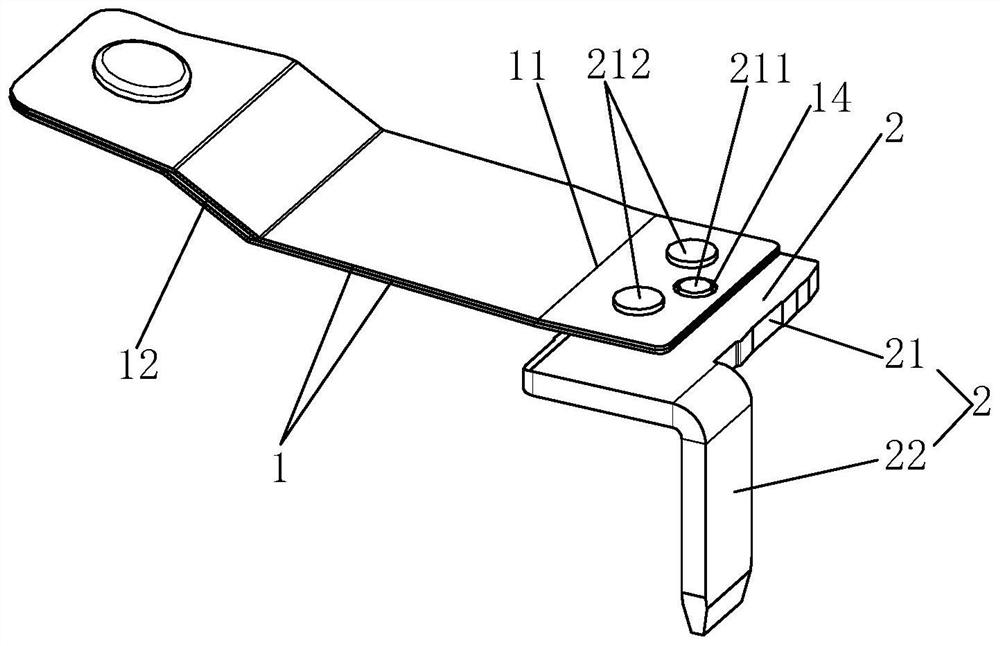

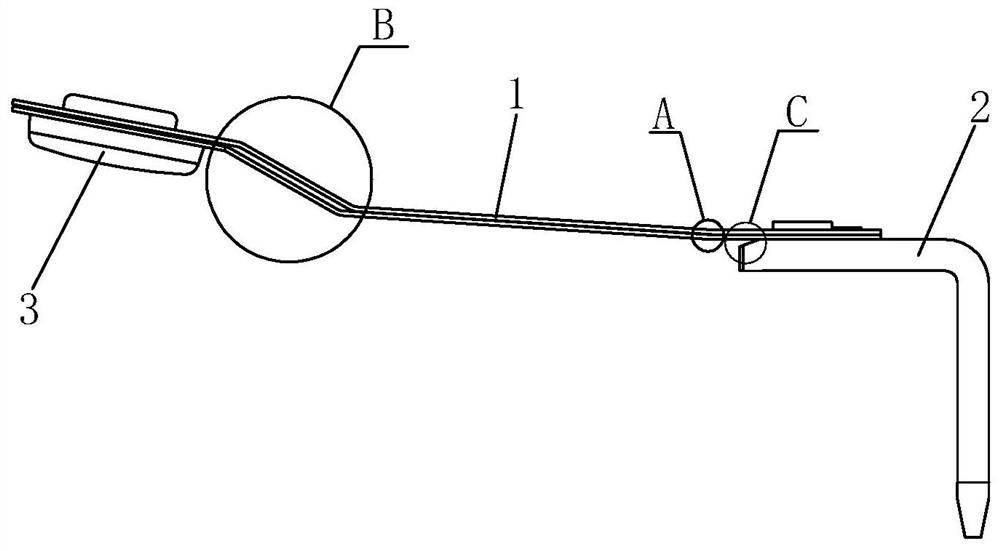

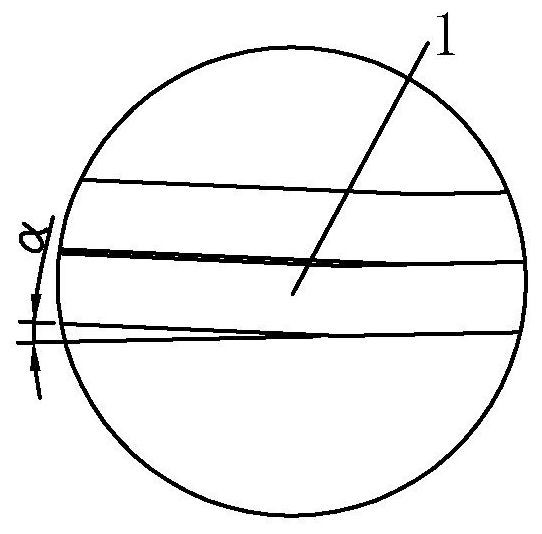

[0036] See Figure 1-Figure 10 As shown in the figure, a moving spring assembly of a relay according to the present invention includes at least two moving reeds 1, a moving spring lead-out piece 2 and a moving contact 3, the at least two moving springs 1 are superimposed together, and the One ends of the at least two movable reeds 1 are respectively fixedly connected to the movable spring lead-out pieces 2, and the other ends of the at least two movable reeds 1 are respectively fixedly connected to the movable contact 3; The shape and expanded size are the same or basically the same. The number of the moving reeds 1 is specifically two, but not limited to this. Said substantially identical means that there are slight differences in shape / size, which are not easily detectable by the naked eye and can be ignored. The unfolded size refers to the size of the moving reed in a flattened state, which includes the length and / or width of the moving reed in the unfolded state.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com