Full-automatic vertical tool clamp

A tooling and fixture, fully automatic technology, applied in the field of tooling and fixtures, can solve the problems of low level of clamping automation, large footprint of tooling, and less processing surface of parts, so as to improve transmission efficiency and stability, reduce floor space, Effect of reducing travel resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

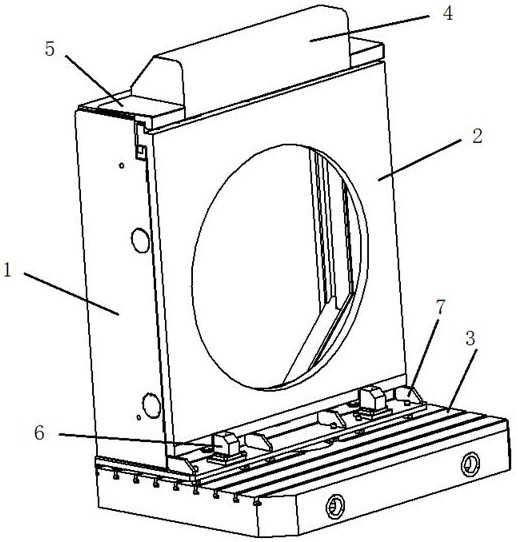

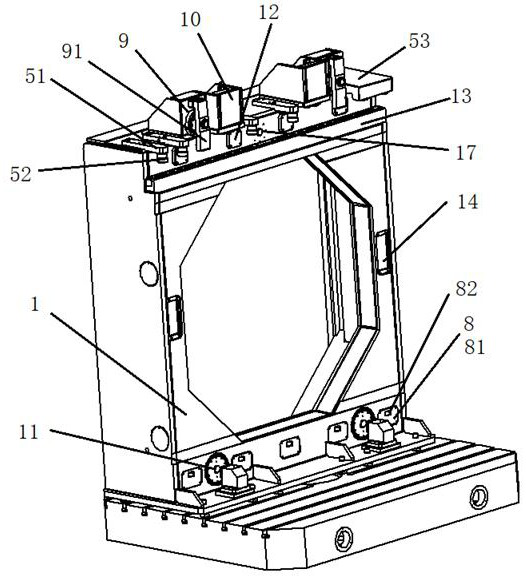

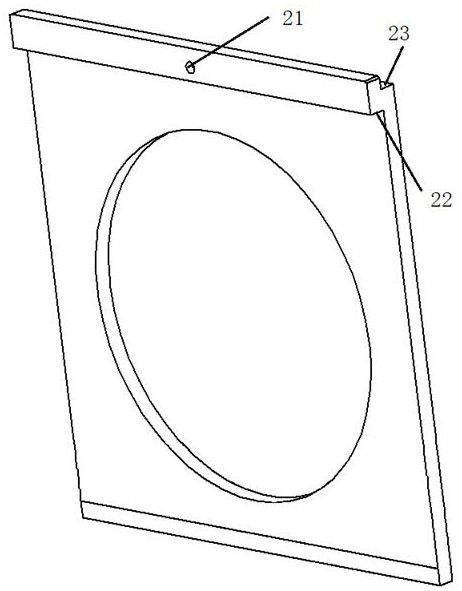

[0026] The present invention provides a fully automatic vertical tooling fixture, please refer to Figure 1-5 , including a vertical tooling bracket 1 and a tooling plate 2, the vertical tooling bracket 1 is used as the clamping support surface of the tooling plate 2, an electromagnetic chuck 14 is installed in the middle of the vertical tooling bracket 1, and the electromagnetic chuck 14 is provided with two groups. A travel switch 15 is installed on the top of the tooling bracket 1 to detect whether the tooling plate 2 is transported to an appropriate position. A top cover 16 is installed on the top of the vertical tooling bracket 1, and an induction switch 18 is installed on the top of the top cover 16. Vertical The base of the tooling bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com