Equipment and process for producing polyurethane intermittent cold storage plate and refrigerator car heat insulation plate

An intermittent, cold storage board technology, applied to other household appliances, flat products, household appliances, etc., can solve the problems of not being able to produce national standard B1 fireproof products, failing to achieve thermal conductivity, long foaming molding time, etc., to achieve good quality Requirements, good thermal insulation performance, and short foaming molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention. In addition, the configurations of the structures described in the following embodiments are only examples. The batch production of polyurethane involved in the present invention The equipment and process of type cold room panels and refrigerated car insulation panels are not limited to the structures described in the following embodiments, all other embodiments obtained by those of ordinary skill in the art without creative work Belong to the protection scope of the present invention.

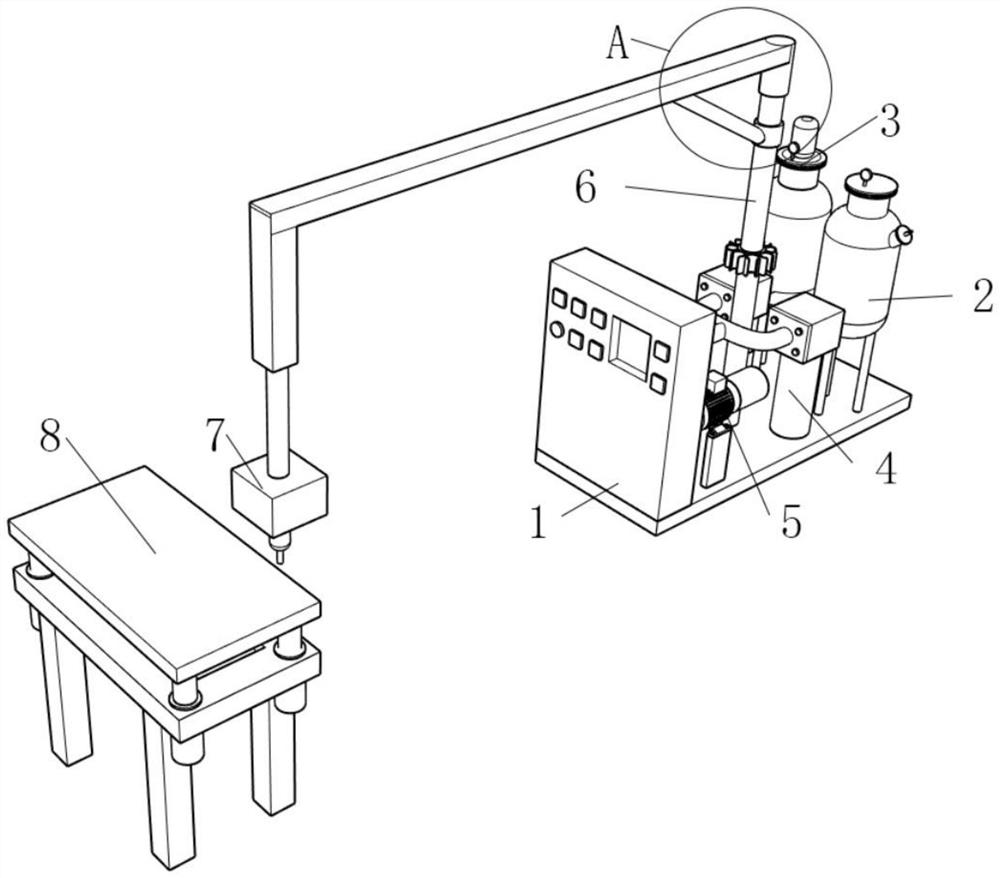

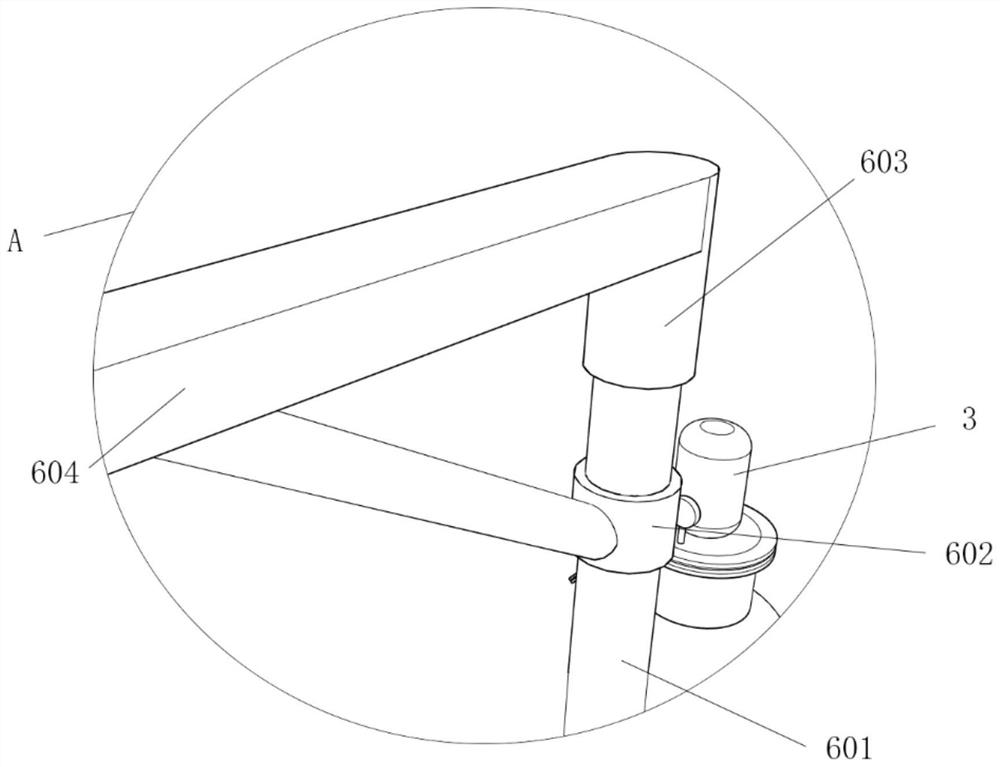

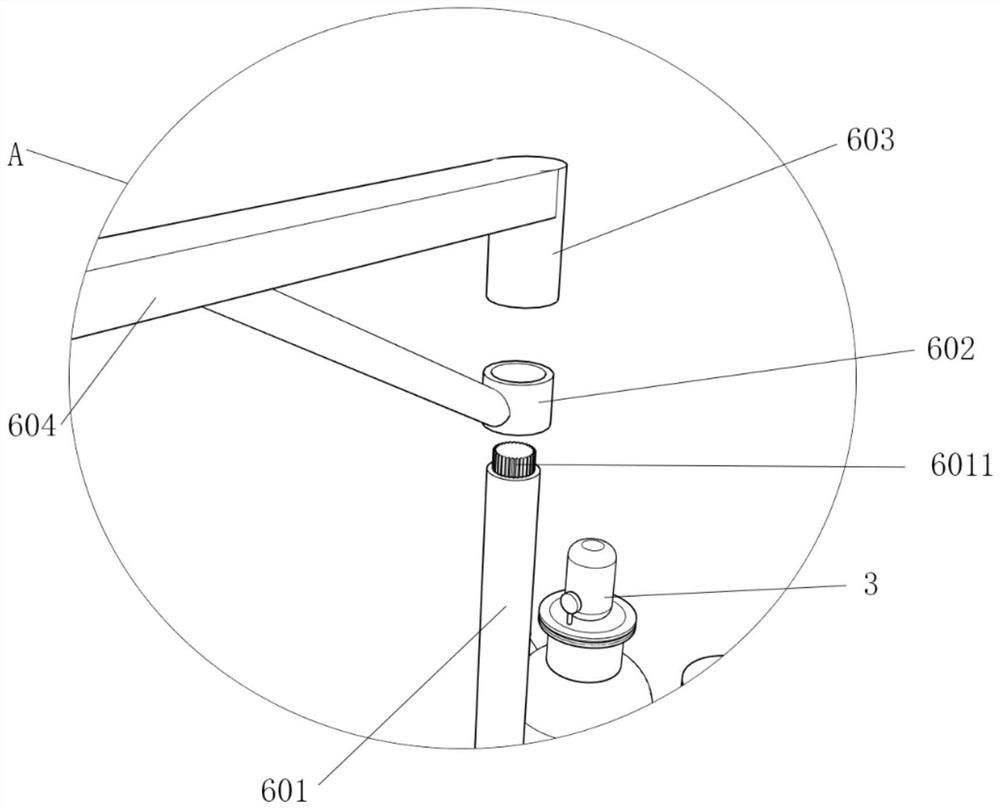

[0036] refer to Figure 1-7 , the present invention provides a kind of equipment and process for producing polyurethane intermittent cold storage boards and refrigerated car insulation boards, comprising a base 1, the top side of the base 1 is fixedly connected with a B material tank 2, and one side of the B material tank...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap