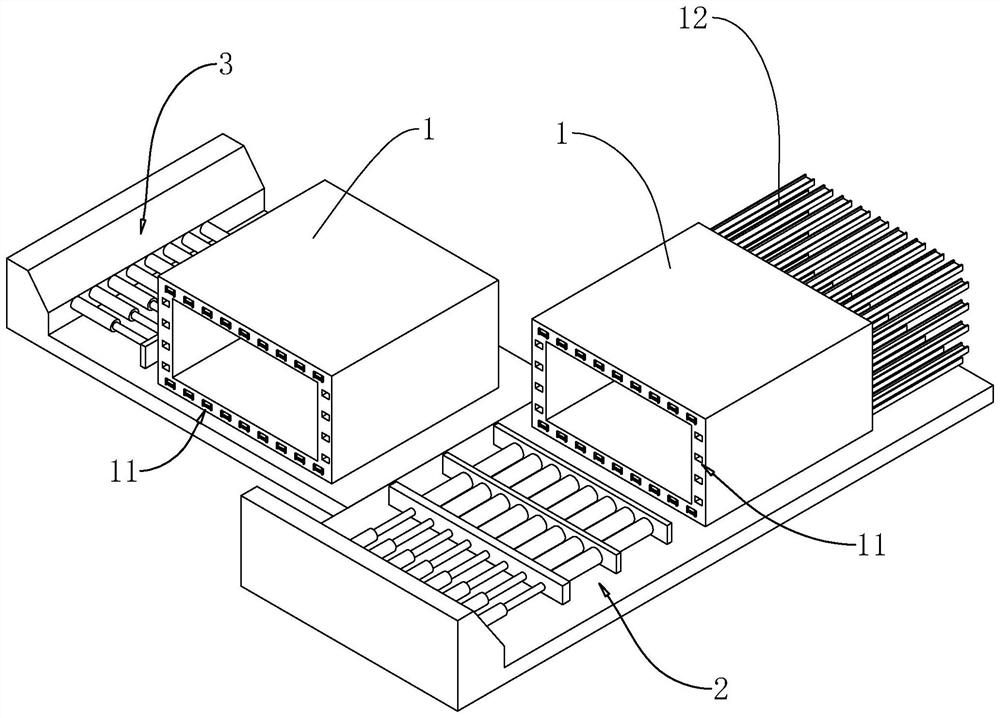

Framework box culvert jacking structure of underneath passing railway and construction method of frame box culvert jacking structure

A jacking and box culvert technology, applied in underwater structures, infrastructure engineering, excavation, etc., can solve the problems of small space, inconvenient construction, and difficulty in reserving enough space, and achieve the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

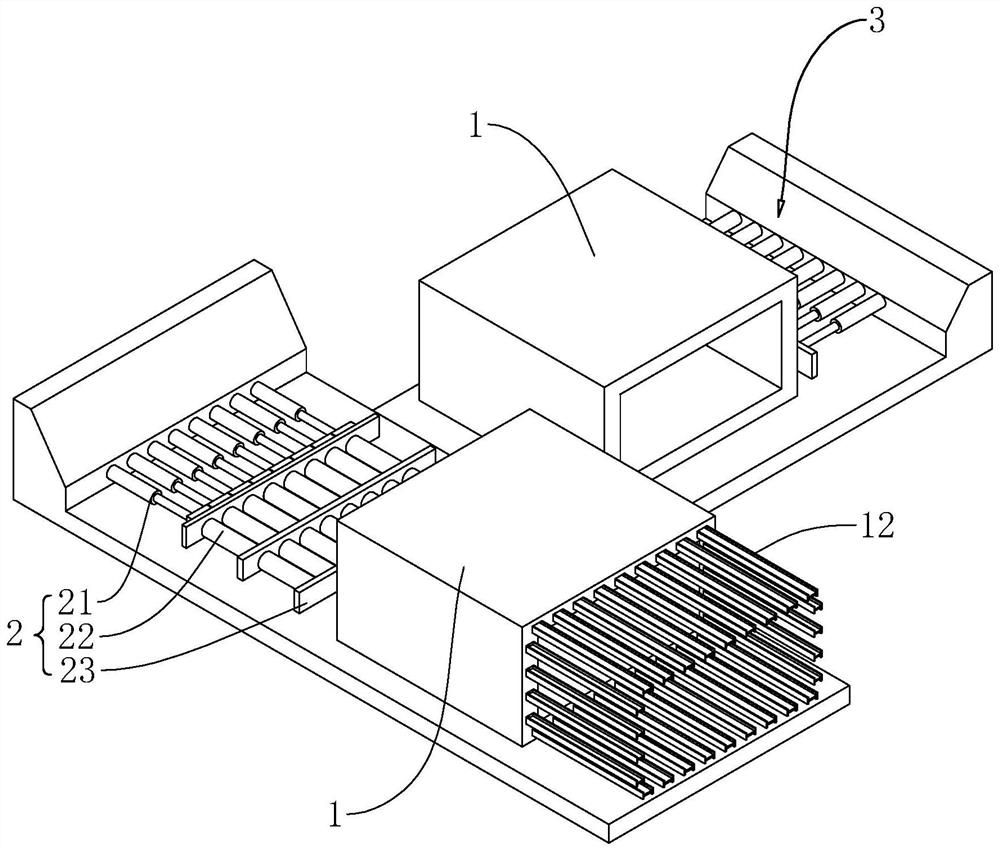

Method used

Image

Examples

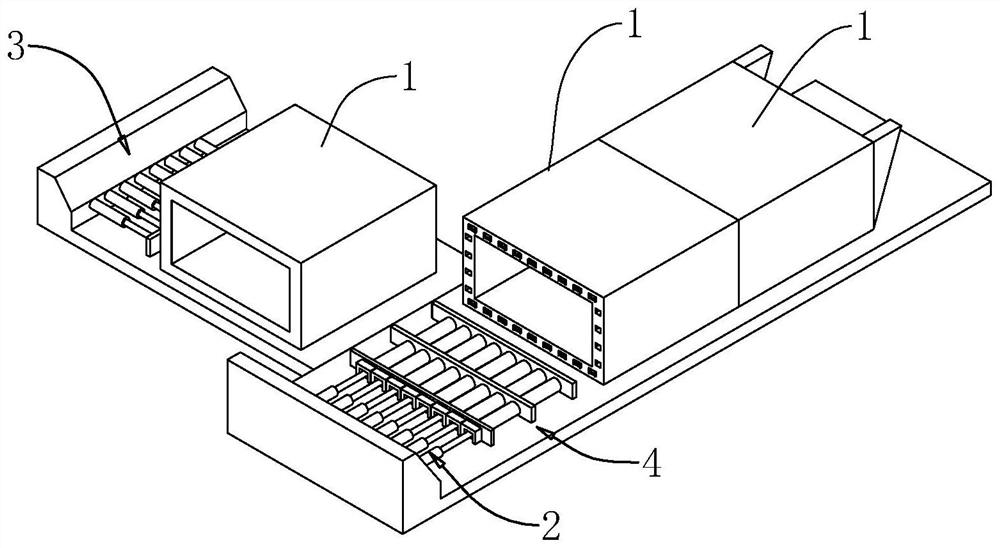

Embodiment 2

[0057] The embodiment of the present application discloses a frame box culvert jacking structure passing through a railway. image 3 , the difference from Embodiment 1 is that the hydraulic jacking member 21 is detachably connected with an abutment mechanism 4, and the abutment mechanism 4 includes a top member 41, a mounting plate 42, an extension member 43 and an abutment member 44. The top member A plurality of 41 are provided, and one jack 41 is fixed on the piston rod of one hydraulic jack 21 . The mounting plate 42 is detachably connected to the top piece 41 , the mounting plate 42 is detachably connected to the abutting piece 44 , the abutting piece 44 is used to push against the outer wall of the box culvert 1 , and the extension piece 43 is arranged on the mounting plate 42 and abutting Between the pieces 44, the mounting plate 42 and the abutting piece 44 can be detachably connected to the extension piece 43, and the extension piece 43 is used to extend the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com