City gate opening-shaped tunnel corner excavation equipment

A city gate hole-shaped and tunnel technology, which is applied in the field of excavation equipment for the side and corner of city gate hole-shaped tunnels, can solve problems such as damage to a swinging oil cylinder, and achieve the effects of improving service life, ensuring safety, and having a compact overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

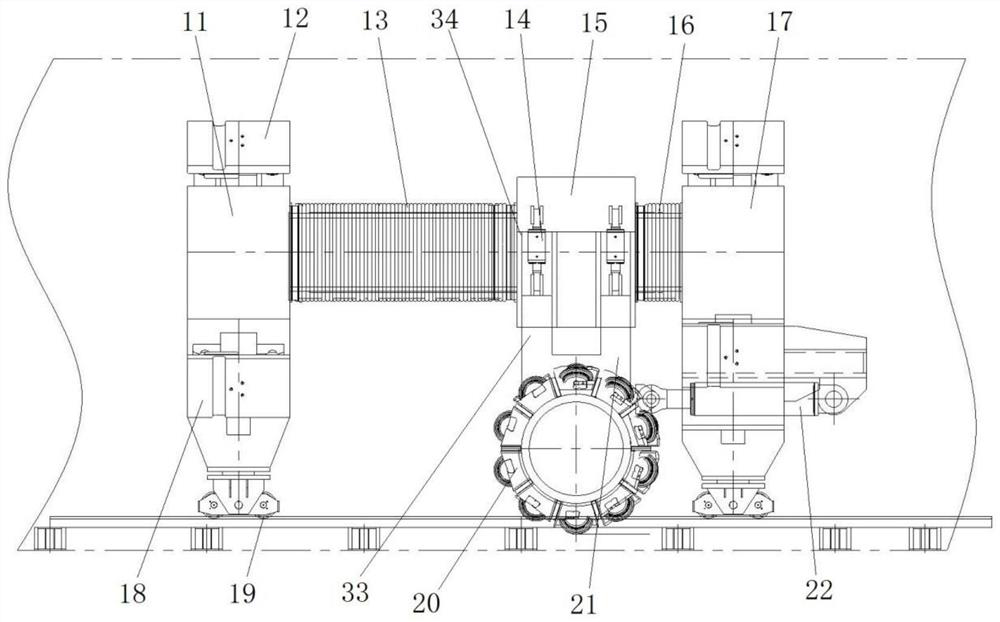

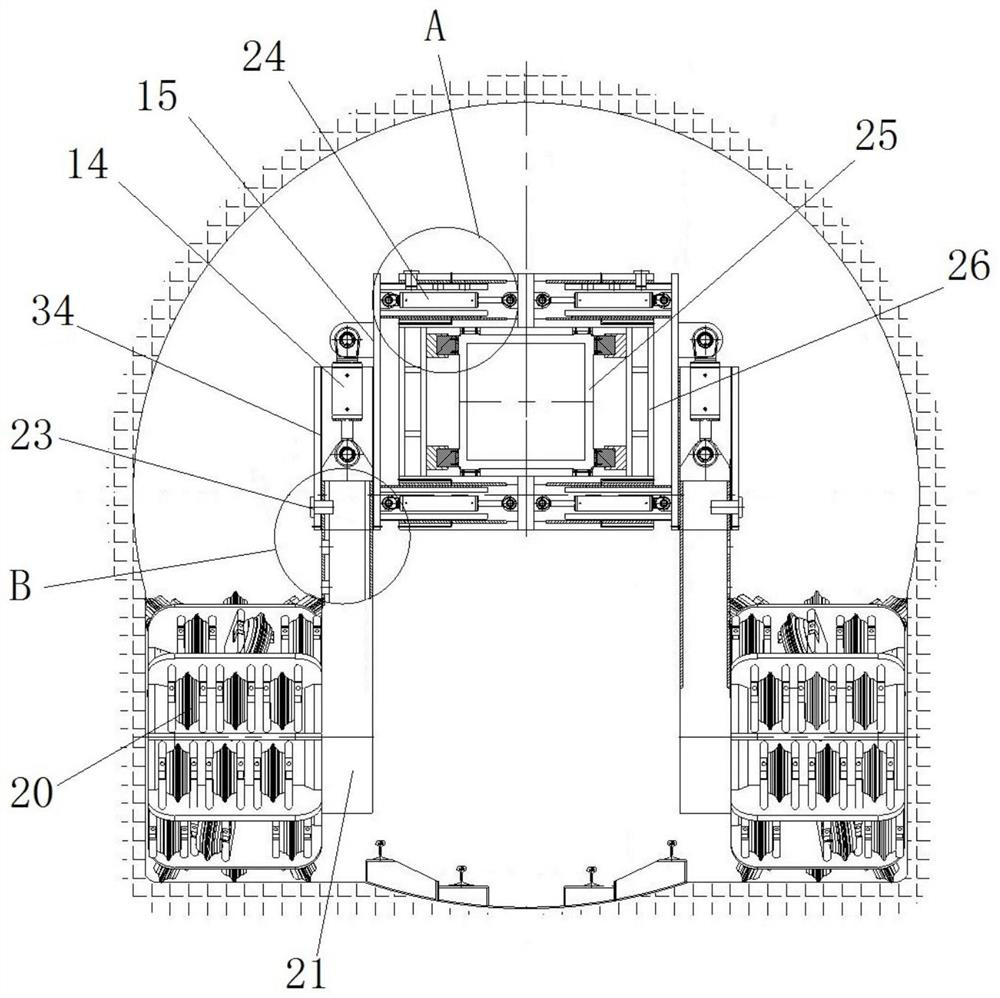

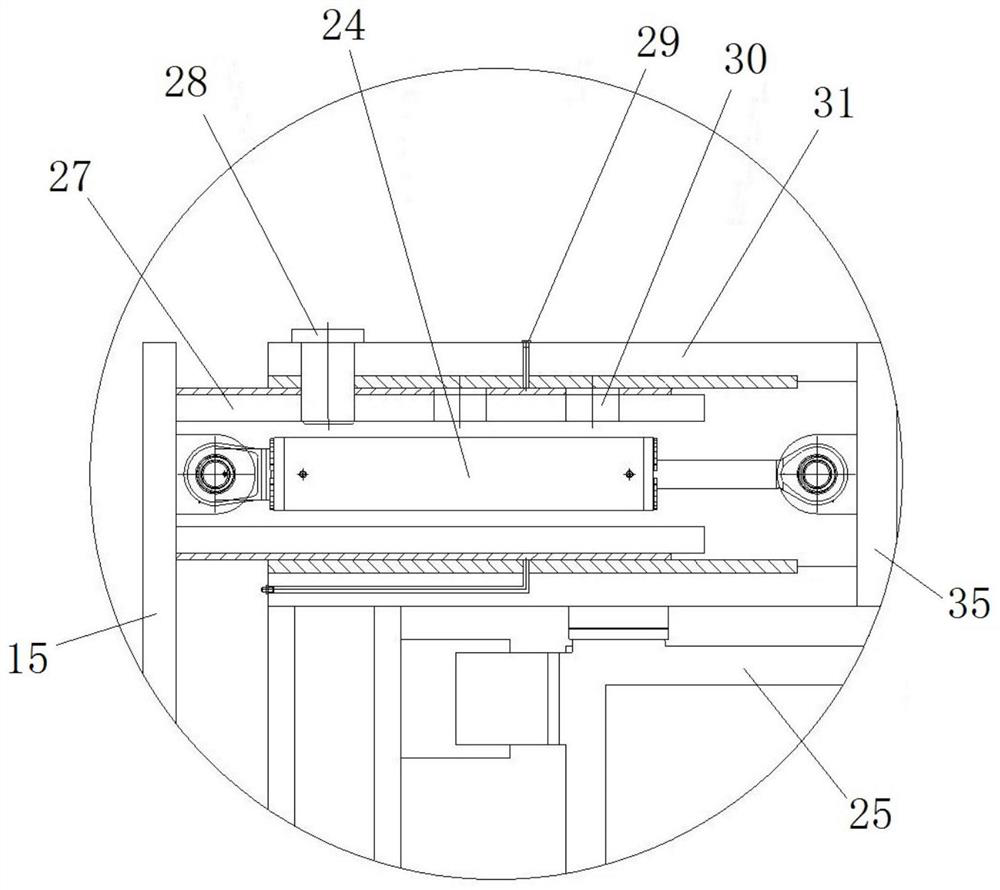

[0037] like figure 1 and figure 2As shown, the excavation equipment for the corners of the city gate tunnel comprises a main beam 25 and a sliding sleeve 26, the main beam 25 extends along the front and rear directions, and the sliding sleeve 26 is sleeved outside the main beam 25 and is slidably assembled on the main beam 25 in the front and rear direction. . The front and rear ends of the main beam 25 are respectively connected with other equipment of the roadheader.

[0038] In this embodiment, the main beam 25 is provided with a front support body 11 and a rear support body 17 outside the sliding stroke of the sliding sleeve 26, that is, the sliding sleeve 26 is located between the front support body 11 and the rear support body 17, and the two support bodies Support boots on both. Wherein, the lower parts of the front support body 11 and the rear support body 17 are provided with traveling wheels 19 to facilitate the movement of the entire excavation equipment.

[00...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that, in Embodiment 1, the vertical guide structure is a vertical guide sleeve, and the upper part of the knife arm is guided and slidably assembled in the vertical guide sleeve in the up-down direction. In this embodiment, the vertical guide structure is a vertical guide rail, the vertical guide rail is provided with a T-shaped groove extending in the up-down direction, the upper part of the knife arm is provided with a protrusion extending in the up-down direction, and the protrusion is connected with the T-shaped groove. adaptation. In other embodiments, the T-slots may be replaced by dovetail slots.

Embodiment 3

[0061] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the vertical locking member is the first locking pin, the vertical guide sleeve is provided with a first locking hole, and the upper part of the knife arm is provided with a second lock locking holes, a plurality of second locking holes are arranged at intervals along the up-down direction, and the first locking pin shafts are inserted into the corresponding first locking holes and the second locking holes to connect the upper part of the knife arm to the vertical guide The sleeves lock together. In this embodiment, the vertical locking member is a set screw, the vertical guide sleeve is provided with a threaded hole, and the upper part of the knife arm and the vertical guide sleeve are locked together by the set screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com