Compact magnetofluid sealing transmission device

A magnetic fluid sealing and transmission technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of shortened length and high cost of cross roller bearings, and achieve the effect of shortened length, simplified structure and the purpose of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

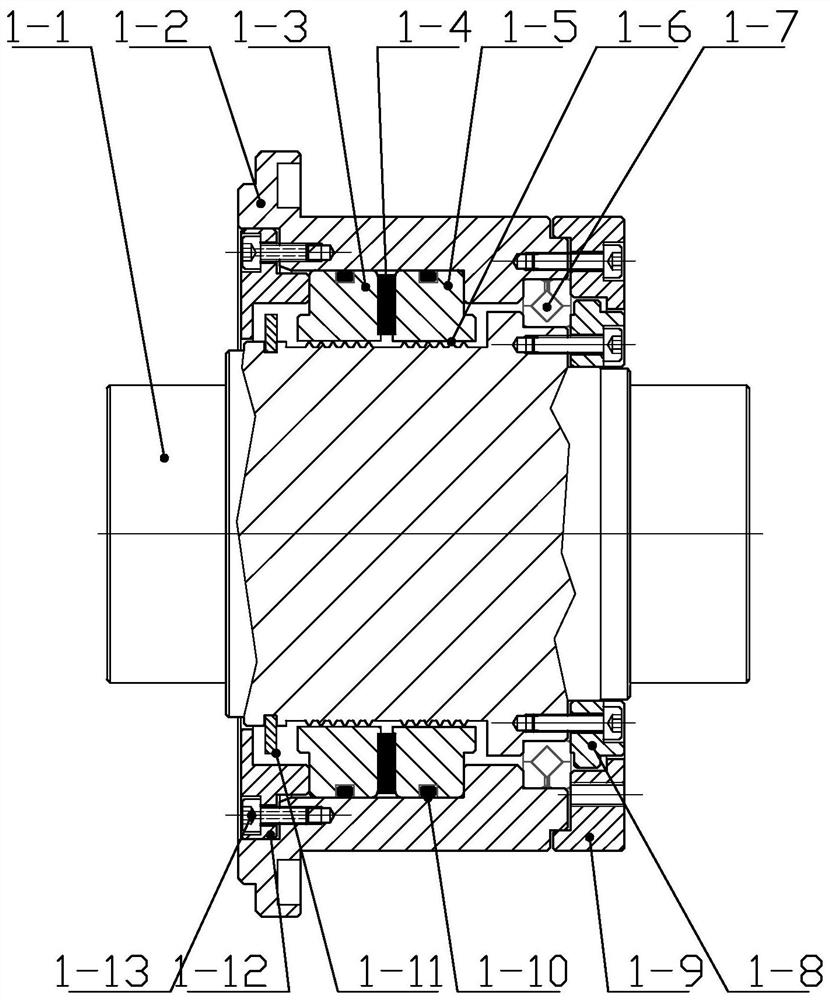

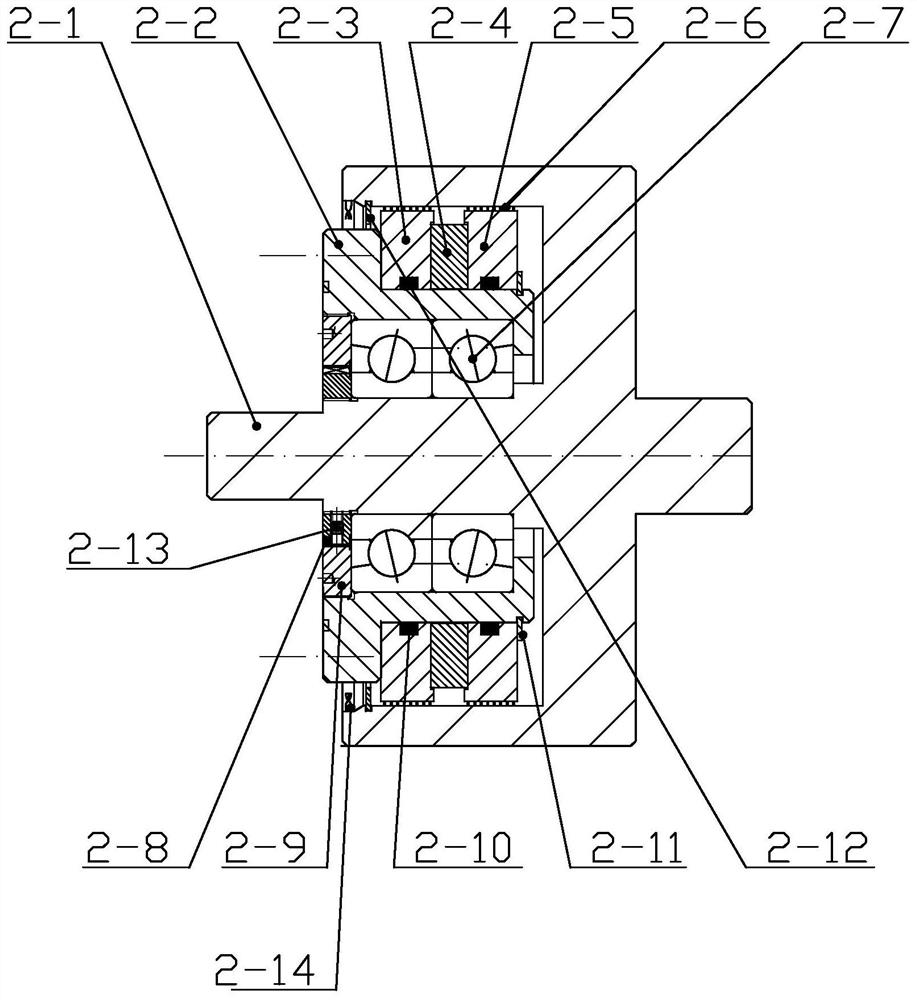

[0027] like figure 1 , 2 As shown in the figure, a compact magnetic fluid seal transmission device includes a cantilevered seal assembly disposed between the main shaft and the casing, the main shaft is also sleeved with a bearing, and the cantilevered seal assembly is radially disposed on the Bearings on one side. The cantilevered seal assembly includes a magnetic block, and a first magnetic pole and a second magnetic pole are arranged on both sides of the magnetic block in the axial direction; the magnetic pole seal ring is arranged on the side of the first magnetic pole and the second magnetic pole close to the bearing. , the first magnetic pole and the second magnetic pole are provided with magnetic fluid for filling the gap on the side away from the bearing. In this application, the magnetic fluid adopts colloidal magnetic fluid.

[0028]The cantilevered seal assembly can be radially arranged on the outside or inside of the bearing. No matter which side of the bearing ...

Embodiment 2

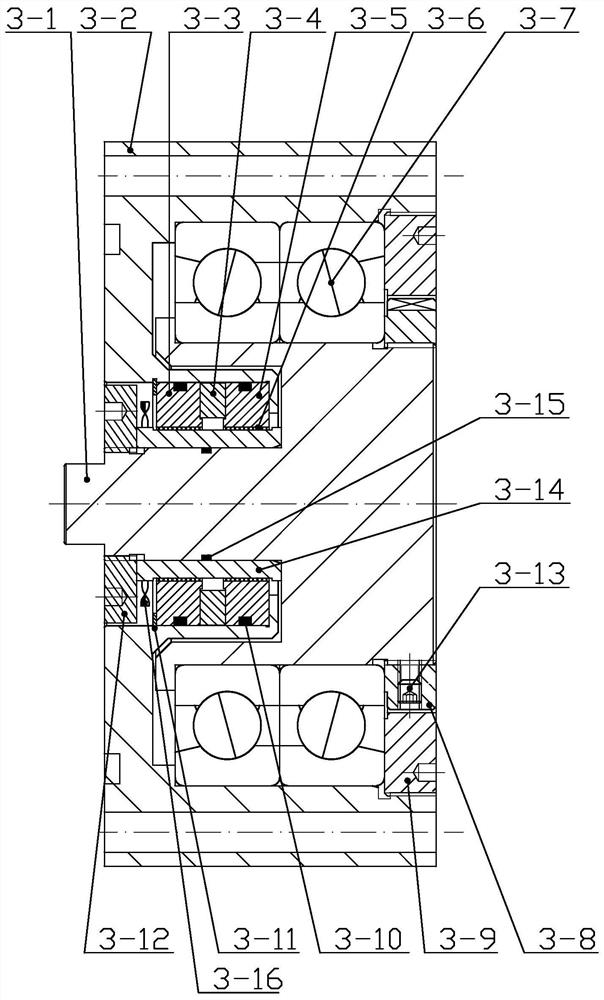

[0033] like image 3 As shown, the difference from Embodiment 1 is that in this embodiment, the cantilevered seal assembly is radially disposed inside the bearing, a shaft sleeve is disposed between the cantilevered seal assembly and the main shaft, and the outside of the shaft sleeve Sealing teeth 3-16 are arranged along the axial direction, and the magnetic fluid is filled in the tooth grooves of the sealing teeth. In this structure, a casing 3-2, a sealing assembly and a bearing 3-7 are included; the sealing assembly includes a main shaft 3-1, a magnetic block 3-4, a first magnetic pole 3-3 disposed on both sides of the magnetic block 3-4, and The second magnetic pole 3-5, the magnetic fluid 3-6 arranged between the main shaft sleeve 3-14 and the matching gap between the first magnetic pole 3-3 and the second magnetic pole 3-5; the sealing assembly is located between the casing 3-2 and the main shaft shaft Between the sleeves 3-14, the magnetic fluid seal transmission devi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap