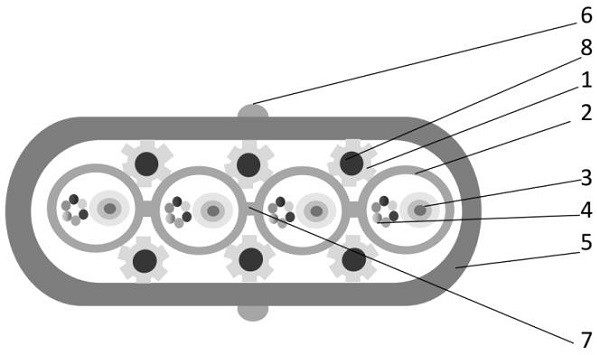

Multi-row easy-to-identify strip-shaped composite optical cable and manufacturing method thereof

A manufacturing method and composite optical cable technology, applied in optics, light guides, optical components, etc., can solve problems such as inconvenient construction and installation, difficulty in troubleshooting problem points, inconvenient maintenance, etc., and achieve the effect of improving efficiency and saving household costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This embodiment provides a method for manufacturing multi-row and easily identifiable ribbon-shaped composite optical cables, wherein the method includes the following specific steps:

[0081] (1) Production of circular optical fiber ribbon:

[0082] The six colored optical fibers are drawn from the fiber pay-off frame to the belt mold through the guide wheel, and the tension of the optical fiber pay-off is controlled to 80g, and the belt mold port is connected to the resin coating cup through the connecting conduit, and passed through the resin coating cup. The adjustment of the barometer valve and the selection of the belt mold control the flow rate of the acrylic resin coating, and the viscosity of the surface of the coating resin is controlled by adjusting the lamp power of the curing furnace;

[0083] The optical fiber coated with acrylic resin comes out of the belt mold and then enters the curing furnace for curing. The curing furnace adopts LED lamps for curing. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com