Manual-automatic integrated high-voltage power distribution cabinet protection pressing plate

A technology of high-voltage power distribution cabinet and protection pressure plate, which is applied in emergency protection circuit devices, electrical components, circuit devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

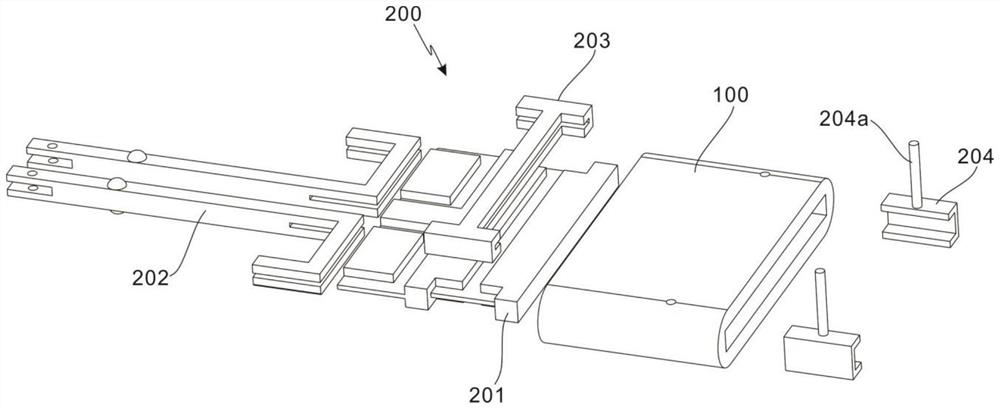

[0029] refer to figure 1 , which is the first embodiment of the present invention. This embodiment provides a manual-integrated high-voltage power distribution cabinet protection pressure plate, including a housing 100 , a pressure plate assembly 200 and a drive assembly 300 . The shell 100 is used as an outer part, the pressure plate assembly 200 inside the protector, the shell 100 is fixed on the user's high-voltage power distribution cabinet, and can be installed vertically or horizontally. When the pressure plate 201 is embedded inside the shell 100 At this time, the protection device of the whole set of protection pressing plate 201 is in the state of power frequency differential protection.

[0030] The two ends of the housing 100 are communicated with each other. The pressing plate assembly 200 includes a pressing plate 201 inside the housing 100 , a movable rod 202 on the upper part of the pressing plate 201 , and a first contact electrode 203 on the upper part of the ...

Embodiment 2

[0033] refer to Figures 1 to 6 , which is the second embodiment of the present invention, which is the same as the previous embodiment.

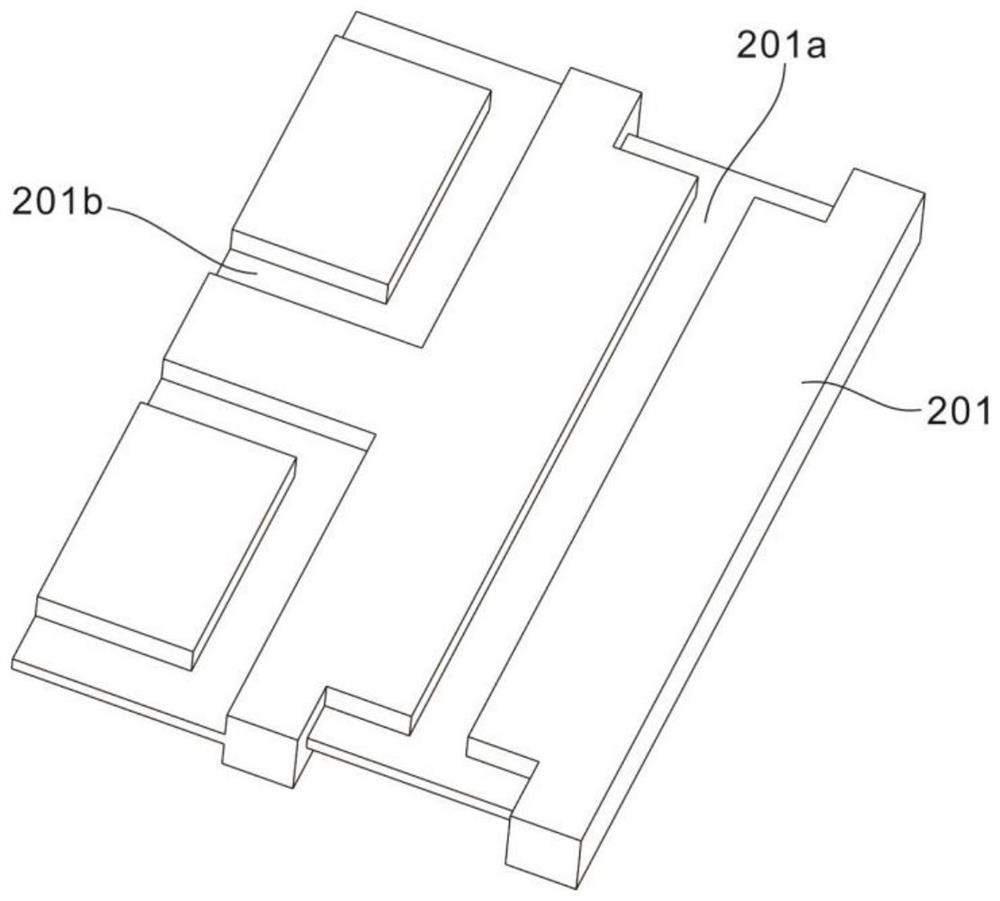

[0034] The first contact electrode 203 is I-shaped, the first contact electrode 203 is hollow, and the first contact electrode 203 is sleeved on the pressing plate 201 . The first contact electrode 203 is used to connect the positive and negative electrodes of the protection pressure plate 201 when the power frequency pressure plate is put in. It is made of brass and has good conduction characteristics.

[0035] The pressing plate 201 is provided with a first connecting groove 201a, the first connecting groove 201a is correspondingly disposed with the first contact electrode 203, the first contact electrode 203 is sleeved on the pressing plate 201 through the first connecting groove 201a, and the first contact electrode 203 and the pressing plate 201 Surface flush setting. The first connection groove 201a is used to realize the sleeve of ...

Embodiment 3

[0040] refer to Figures 1 to 6 , is the third embodiment of the present invention, which is the same as the previous embodiment.

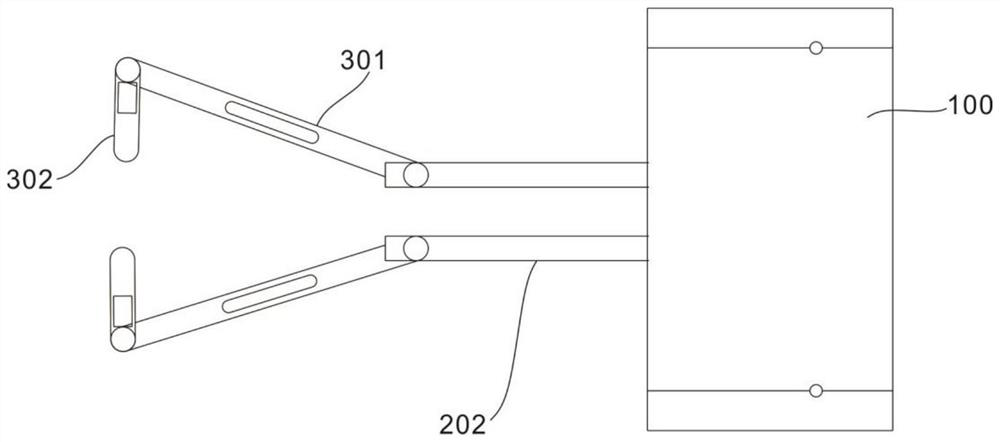

[0041] The drive assembly 300 includes a guide rod 301, a drive rod 302 and a turntable 303. One end of the guide rod 301 is rotatably connected to the movable rod 202, and the other end of the guide rod 301 is rotatably connected to the drive rod 302. One end of the drive rod 302 is provided with a slider 304. 302 is slidably connected to the turntable 303 through the slider 304 .

[0042]The guide rod 301 is made of brass, which can maintain the connection of the circuit during the movement. The horizontal motion of the driving rod 302 is converted into the vertical motion of the movable rod 202 through the guide rod 301. The driving rods corresponding to the rods 202 are arranged in opposite directions of horizontal movement, that is, the two driving rods 302 can realize the input and cutting operations of the pressing plate 201 through the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com