Box collision prevention mechanism of box pasting inspection machine

A product inspection machine and anti-collision box technology, which is applied in sorting and other directions, can solve problems such as box deformation, unstable handling, unstable force, and box collision, and achieve stable and reliable work, reduce box collision, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are only used to more clearly illustrate the technical solutions of the present invention, and are therefore only used as examples, and cannot be used to limit the protection scope of the present invention. It should be noted that, unless otherwise specified, the technical or scientific terms used in this application should have the usual meanings understood by those skilled in the art to which the present invention belongs.

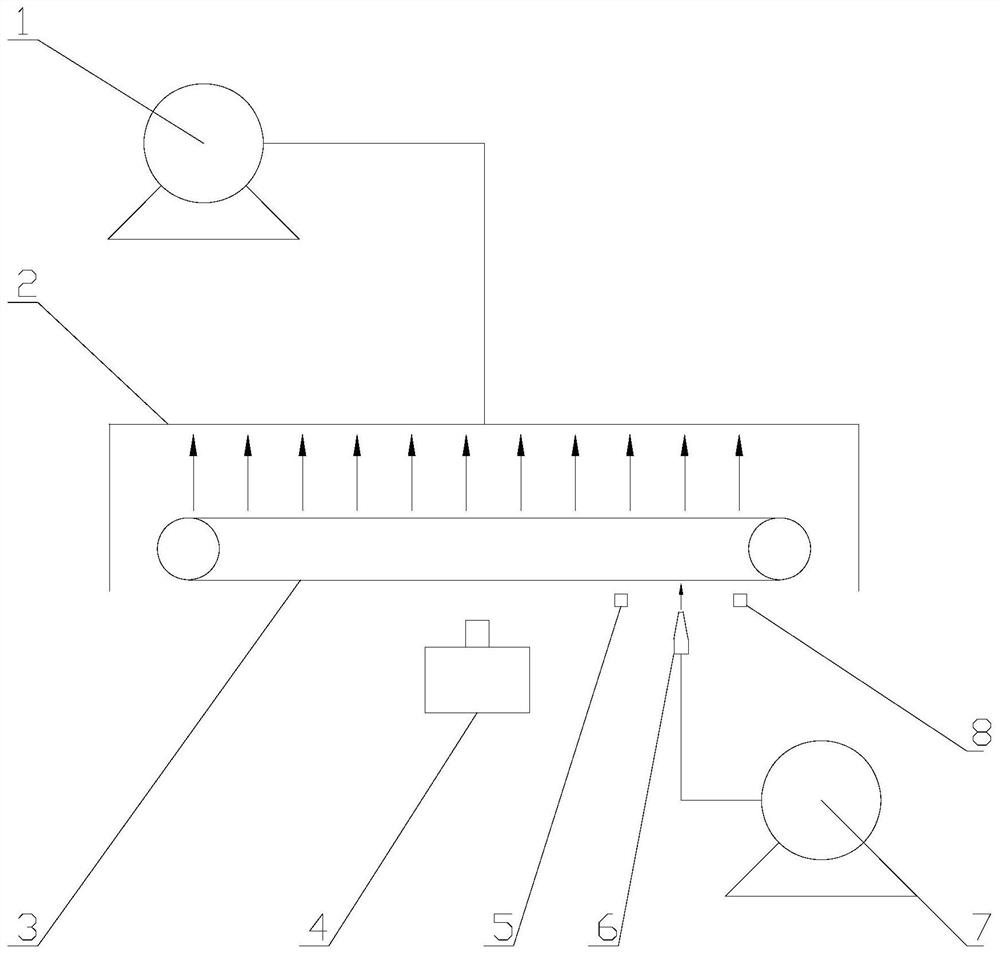

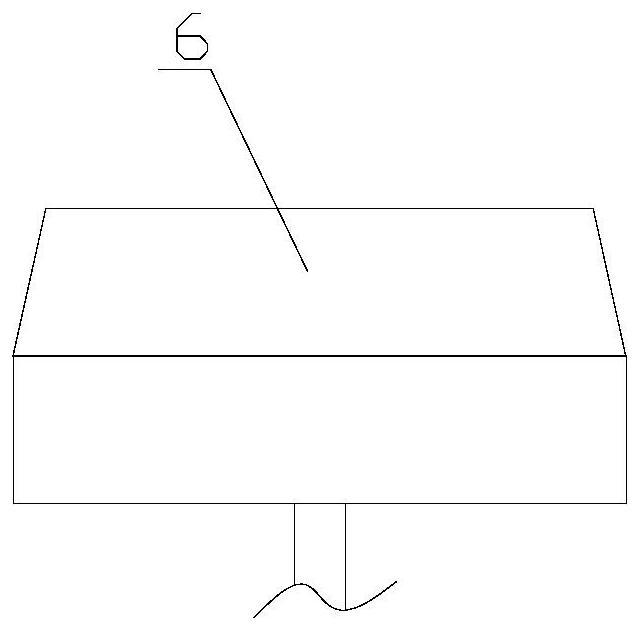

[0019] like figure 1 , figure 2 As shown: the suction belt 3 is installed on the inner lower side of the suction box 2, the two ends of the suction belt 3 are installed on the roller shaft, one of the roller shafts is connected with the drive motor, and the air pump 1 is connected with the upper end of the suction box 2 through a pipeline , a detection camera 4 is arranged under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com