Energy-saving cutting device for continuous casting billet cutting

A cutting device and energy-saving technology, which is applied in the field of energy-saving cutting devices for continuous casting slab cutting, can solve problems such as increased labor intensity, easy splashing around, and potential safety hazards, and achieves reduced labor intensity, reduced splash range, and convenient The effect of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

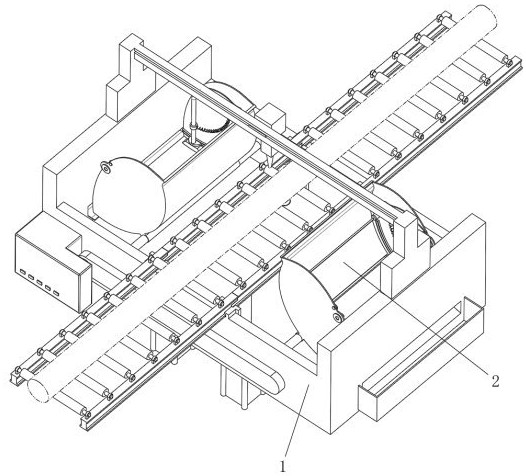

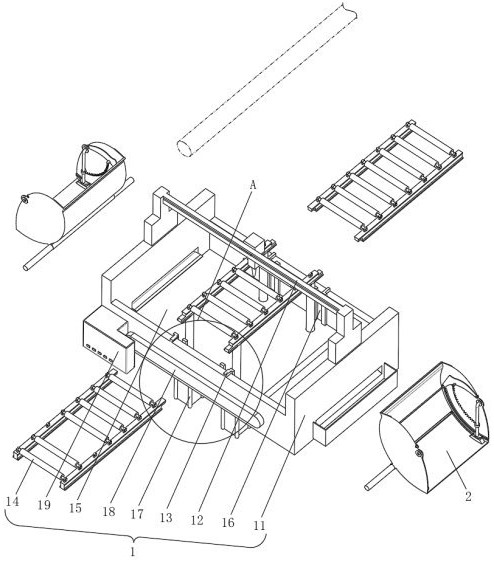

see Figure 1-Figure 8 , the present invention provides a technical solution: an energy-saving cutting device for continuous casting billet cutting, comprising:

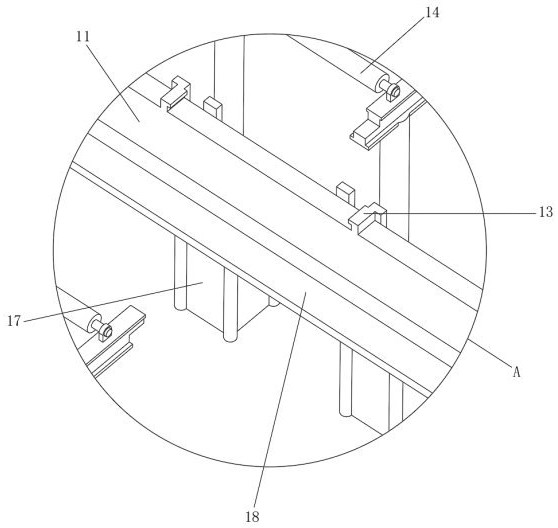

The operating body 1, the operating body 1 includes a placing seat 11, the top of the placing seat 11 is provided with a cutting device 12, and the placing seat 11 is fitted with a conveying frame 14 through a limit block 13 arranged on the top of the placing seat 11;

Placement 2. Placement 2 includes recovery boxes 21. There are two recovery boxes 21 and are symmetrically distributed with the conveying frame 14 as the center. The box 21 is slidably installed with a scraper member 24 through a track 23 provided on the inner wall thereof, and the outer side of the scraper member 24 is adapted to the inner wall of the recovery box 21 .

[0027] There is a working cavity 15 inside the placing seat 11. The conveying frame 14 includes an electric guide rail and rollers. The electric guide rail adopts a segmented design, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com