Spinneret template micropore processing method

A technology of micro-hole processing and spinning, applied in the field of micro-hole processing of spinneret templates, can solve the problems of poor polishing effect and uneven polishing, and achieve the effect of reducing roughness, uniform polishing effect and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

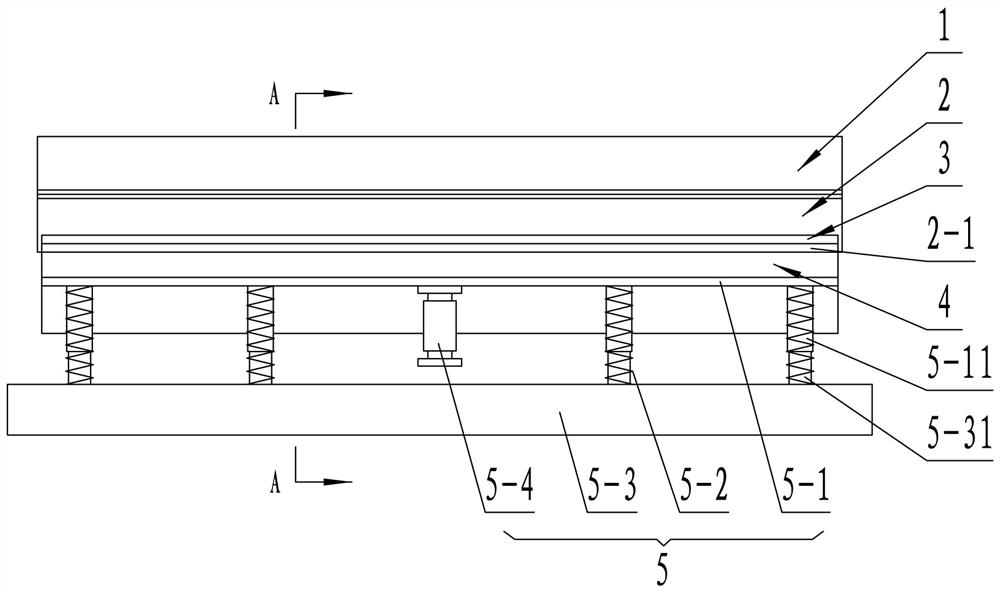

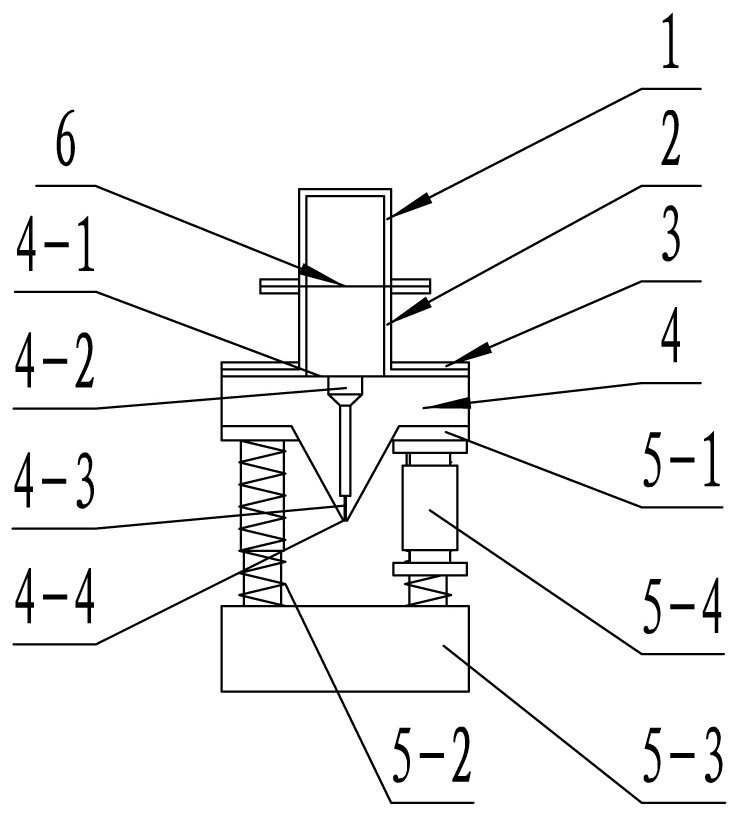

[0029] In the spinneret template microhole processing method of this embodiment, the rotating speed of the drilling tool for drilling the microholes on the spinneret template is 10000 rpm, and the feed rate of the drill tool is 0.03 mm / s. After the microholes are drilled, the following steps are also included :

[0030] A, clean the spinneret template that has drilled micropores with a dry ice blaster, clean the micropores at a speed of 2 cm / s from the feeding surface of the spinneret template and the spinneret surface along the direction of the arrangement of the micropores of the spinneret template, During the cleaning process, the distance from the nozzle of the dry ice blasting machine to the surface of the spinneret plate is 10cm, the injection pressure is 0.6 MPa, and the ice output rate is 0.8kg / min;

[0031] B. Install a material frame on the feed surface of the spinneret template, and the material frame surrounds the feed trough on the spinneret template;

[0032] C....

Embodiment 2

[0038] In the spinneret template microhole processing method of the present embodiment, the rotating speed of the drilling tool for drilling the microholes on the spinneret template is 15000 rpm, and the feed rate of the drill tool is 0.04 mm / s. After the microholes are drilled, the following steps are also included :

[0039] A, clean the spinneret template that has drilled micropores with a dry ice blaster, clean the micropores at a speed of 4 cm / s from the feeding surface of the spinneret template and the spinneret surface along the direction of the arrangement of the micropores of the spinneret template, During the cleaning process, the distance from the nozzle of the dry ice blasting machine to the surface of the spinneret plate is 15cm, the injection pressure is 0.8 MPa, and the ice output rate is 1.2kg / min;

[0040] B. Install a material frame on the feed surface of the spinneret template, and the material frame surrounds the feed trough on the spinneret template;

[0...

Embodiment 3

[0047] In the spinneret template microhole processing method of the present embodiment, the rotating speed of the drilling tool for drilling the microholes on the spinneret template is 20000 rpm, and the feed rate of the drill tool is 0.05 mm / s. After the microholes are drilled, the following steps are also included :

[0048] A, clean the spinneret template that has drilled micropores with a dry ice blaster, clean the micropores at a speed of 5 cm / s from the feeding surface of the spinneret template and the spinneret surface along the direction of the arrangement of the micropores of the spinneret template, During the cleaning process, the distance from the nozzle of the dry ice blasting machine to the surface of the spinneret plate is 20cm, the injection pressure is 1 MPa, and the ice output rate is 1.5kg / min;

[0049] B. Install a material frame on the feed surface of the spinneret template, and the material frame surrounds the feed trough on the spinneret template;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com