High-yield rice segmented harvesting treatment method

A processing method and rice technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of handling threshing experience and proficiency, twisting rice straw into threshing equipment, limitations of production process, etc. Achieve the effects of improved safety, safe and convenient use, and reduced power source settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

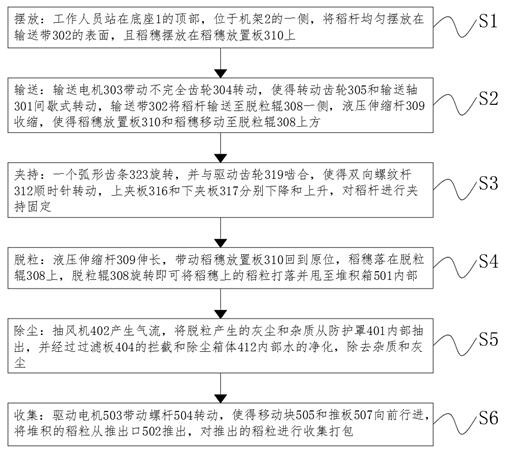

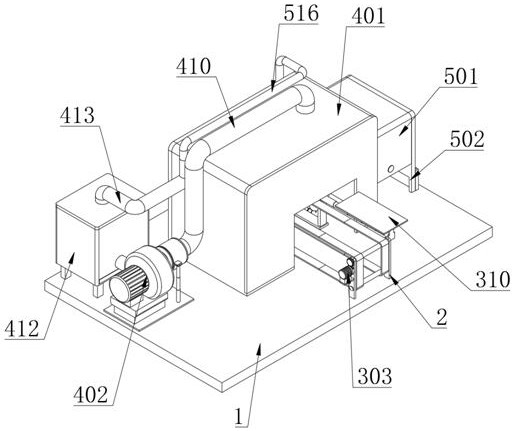

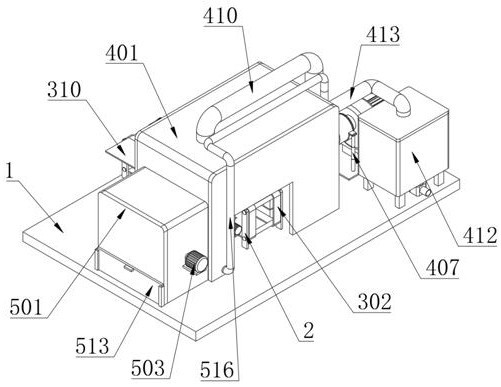

[0047] Example: as figure 1 As shown, the present invention provides a technical solution, a high-yield rice staged harvesting treatment method, comprising the following steps:

[0048] S1, placing: the staff stands on the top of the base 1, on one side of the frame 2, and evenly places the rice straw on the surface of the conveyor belt 302, and the rice ear is placed on the rice ear placing plate 310;

[0049] S2. Conveying: The conveying motor 303 drives the incomplete gear 304 to rotate, so that the rotating gear 305 and the conveying shaft 301 rotate intermittently, the conveying belt 302 conveys the rice straw to the side of the threshing roller 308, and the hydraulic telescopic rod 309 shrinks, so that the rice ears are placed Plate 310 and ear of rice move over threshing roller 308;

[0050] S3. Clamping: an arc-shaped rack 323 rotates and meshes with the driving gear 319, so that the bidirectional threaded rod 312 rotates clockwise, and the upper splint 316 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com