Surface treatment polishing device for mechanical equipment manufacturing for constructional engineering

A mechanical equipment and surface treatment technology, which is applied in the direction of grinding drive devices, metal processing equipment, manufacturing tools, etc., can solve the problems of adjustment of tubular parts of different sizes, inconvenient grinding of cylindrical parts, etc. To achieve the effect of improving stability, improving convenience and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

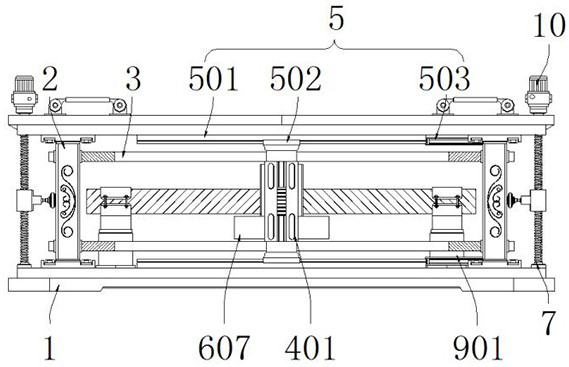

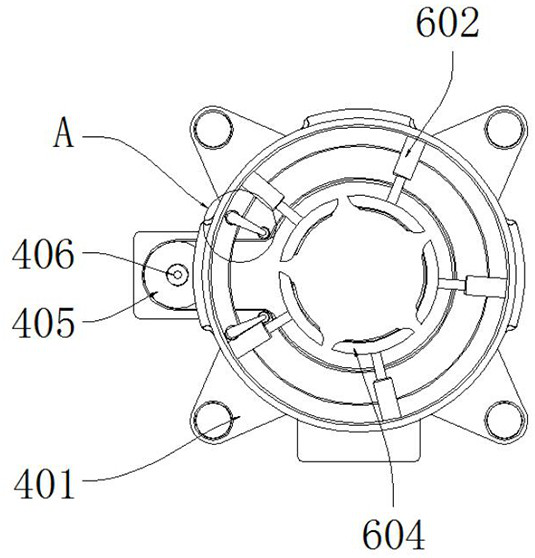

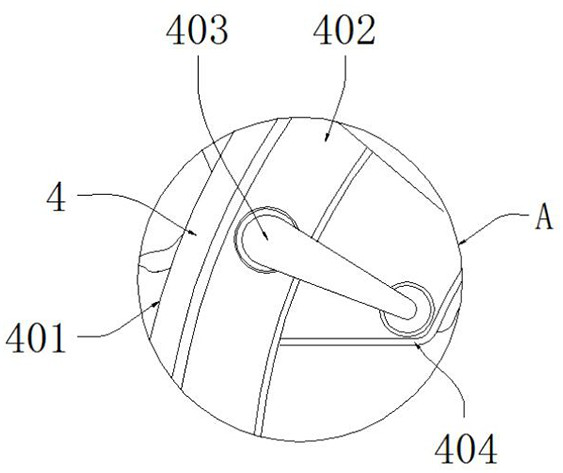

[0022] see Figure 1-Figure 8 , the present invention provides a technical solution: a surface treatment and grinding device for manufacturing mechanical equipment for construction engineering, comprising a base 1 and a limit assembly 6, the top of the base 1 is connected to a limit frame 2, and the surface of the limit frame 2 is provided with a sliding The rod 3, the sliding rod 3 is provided with a grinding component 4 outside, and the grinding component 4 is provided with an adjustment component 5 outside. The grinding component 4 includes a grinding frame 401, a driving frame 402, a wear-resistant roller 403, a grinding plate 404, a transmission wheel 405 and a drive Motor 406, a driving frame 402 is installed on the inner wall of the grinding frame 401, and a wear-resistant roller 403 is arranged on the inner wall of the driving frame 402, a grinding sheet 404 is movably arranged on the surface of the wear-resistant roller 403, and a driving wheel 405 is arranged inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com