Feed dog assembly of sewing machine

A technology of feeding dog and sewing machine, applied in sewing machine components, sewing equipment, feeding mechanism and other directions, can solve the problems of high transmission efficiency, complex mechanical transmission mechanism, low manufacturing difficulty, etc., and achieves improved transmission efficiency, high promotion value, The effect of simplified mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present application will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present application can be more easily understood by those skilled in the art, so that the protection scope of the present application can be more clearly defined. These embodiments It is only used to illustrate the present invention, but not to limit the present invention.

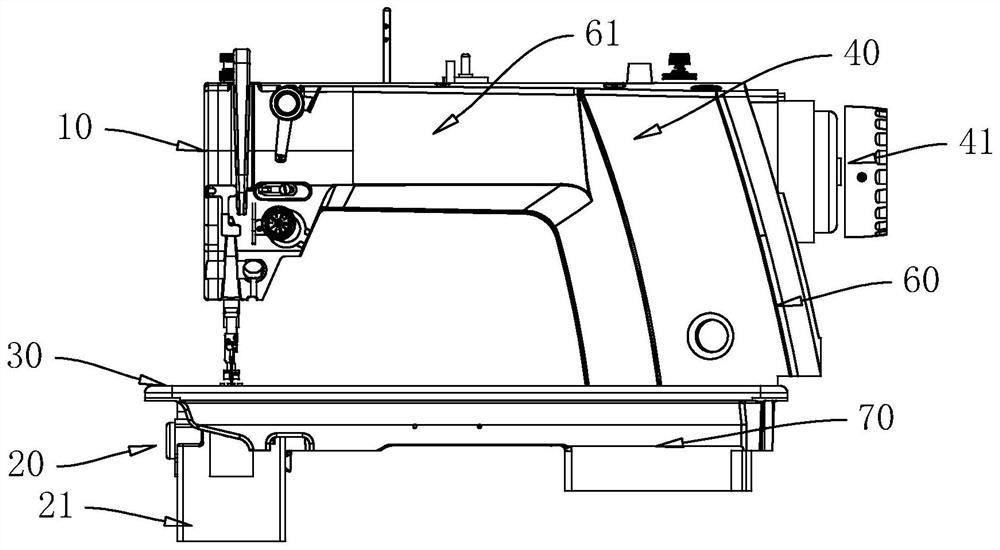

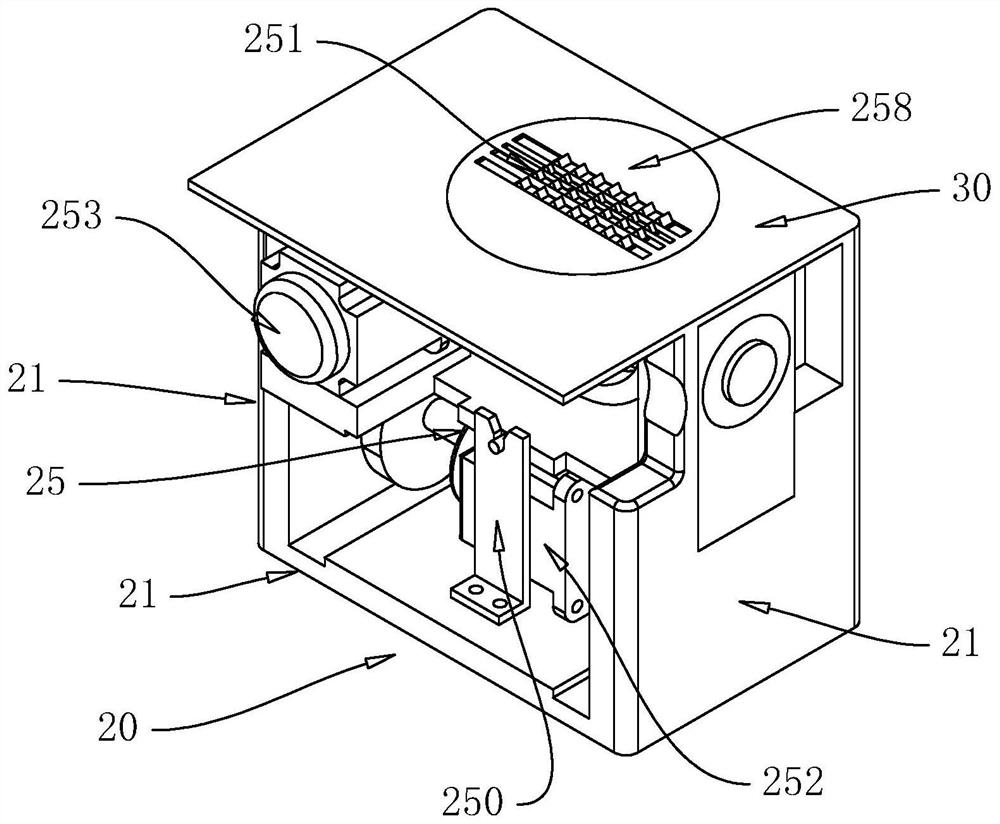

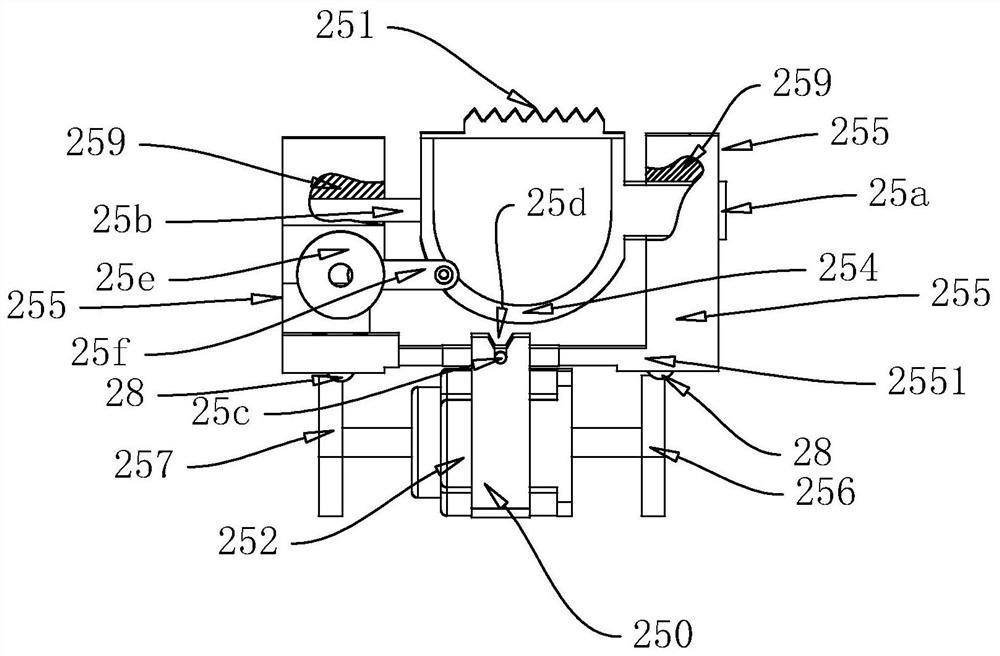

[0023] figure 1 Shown is a schematic structural diagram of a feed dog assembly of a sewing machine of the present application. The feed dog assembly structure of the sewing machine of the present application includes a machine head 40 , a controller 60 , a platen 30 and a base 70 . The above-mentioned handpiece 40 includes an upper thread mechanism 10 , a spindle motor 41 and a controller 60 , and a control operation panel 61 included in the controller 60 is mounted on the front of the handpiece 40 . The lower thread mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com