Balanced oil well layering packer

A packer, balanced technology, applied in the direction of sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve troubles and other problems, and achieve the effect of preventing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

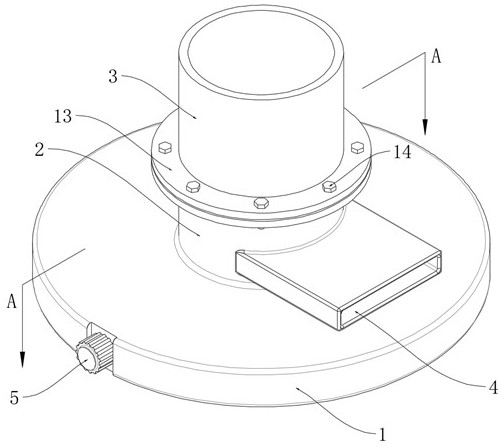

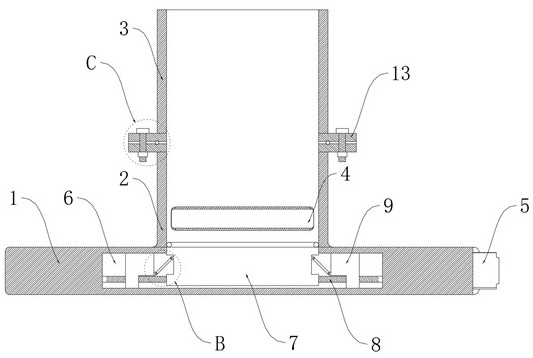

[0018] See e.g. figure 1 A balanced oil well layered packer as shown includes a sealing cover plate 1, a protruding pipe 2 integrally welded to the center of the top wall of the sealing cover plate 1, and an oil delivery pipeline fitted on the top of the protruding pipe 2. 3. An oil outlet pipe 4 is installed laterally on the outer wall of the protruding pipe 2;

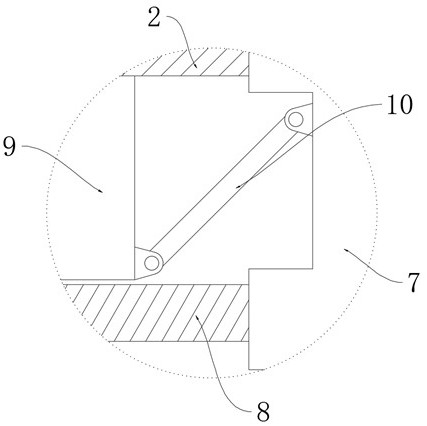

like Figure 2-Figure 4 As shown, an outer motor 5 is welded on one side of the outer wall of the isolation cover plate 1, and an inner chamber 6 isolated from the outside is formed in the isolation cover plate 1, and the inner chamber 6 is provided with a double-patterned connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com