Adaptive supply voltage clamping circuit

An adaptive power supply and voltage clamping technology, which is applied in the direction of adjusting electrical variables, instruments, control/regulation systems, etc., can solve problems such as inapplicability, achieve the effect of enhancing self-adaptive ability and improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

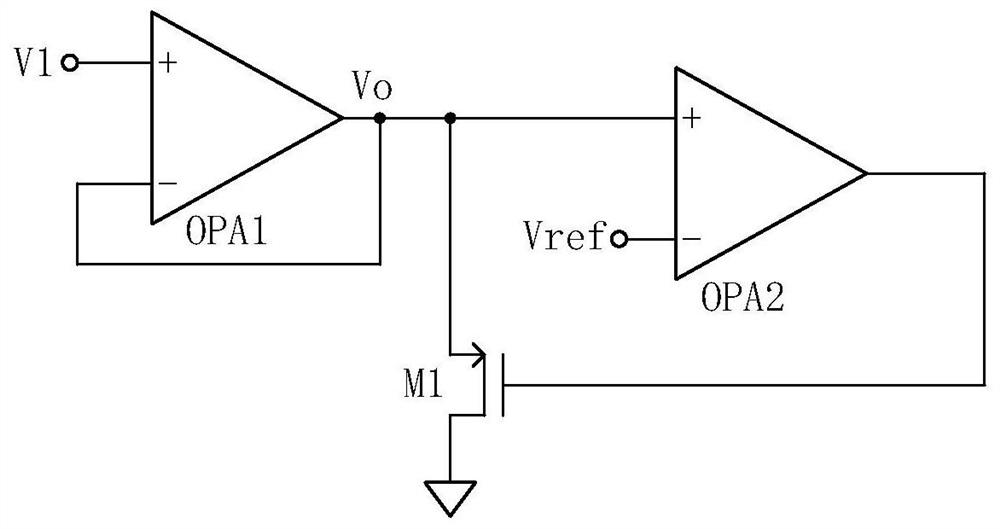

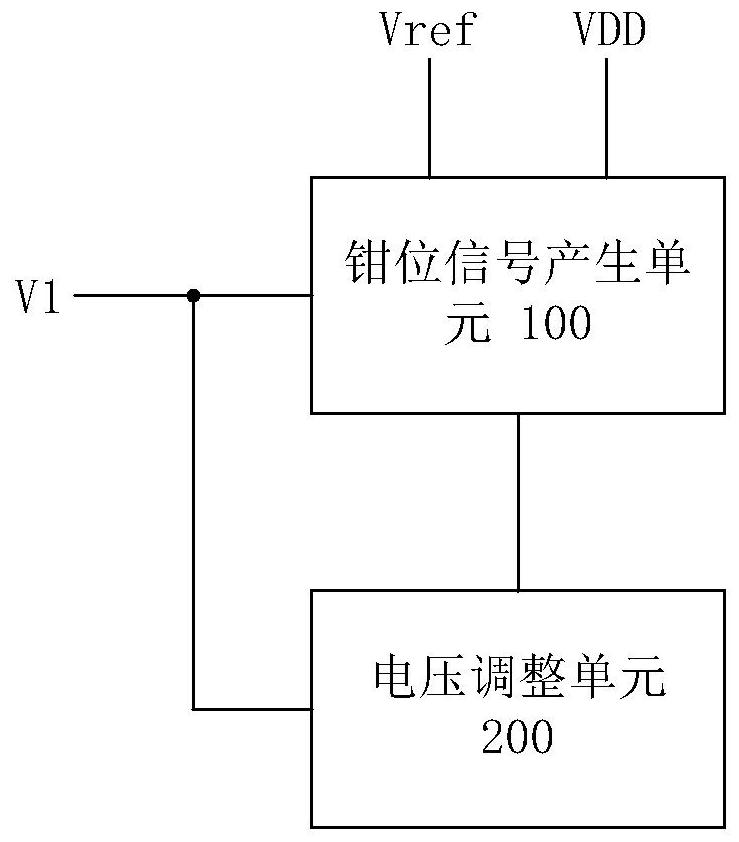

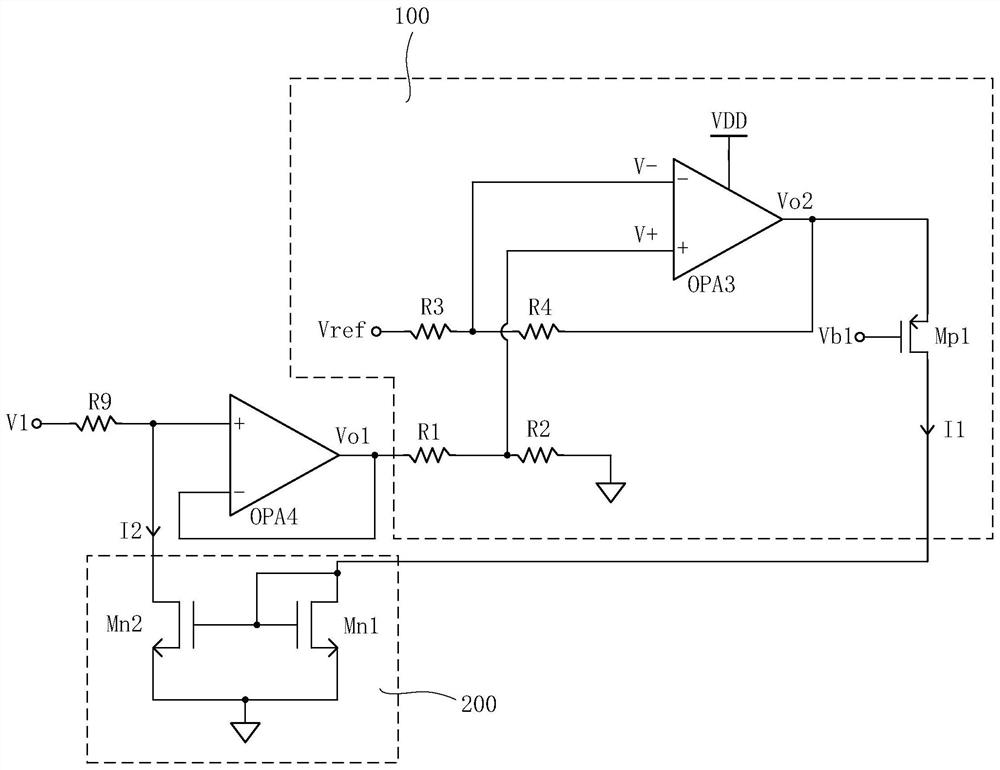

[0051] figure 2 A structural block diagram showing an adaptive supply voltage clamping circuit provided according to an embodiment of the present disclosure, image 3 A schematic circuit structure diagram of the adaptive power supply voltage clamping circuit provided according to the first embodiment of the present disclosure is shown.

[0052] like figure 2 As shown, in this embodiment, the adaptive power supply voltage clamping circuit includes: a clamping signal generation unit 100 and a voltage adjustment circuit 200 .

[0053] Wherein, the first input terminal of the clamping signal generating unit 100 receives the target voltage V1, the second input terminal receives the reference voltage Vref, and the third input terminal receives the power supply voltage VDD, the clamping signal generating unit 100 is used to monitor the target voltage V1, and When it is detected that the difference between the target voltage V1 and the voltage limit value corresponding to the target...

Embodiment 2

[0078] The circuit structure of the self-adaptive supply voltage clamping circuit provided by this embodiment is as follows Figure 4 shown.

[0079] Specifically, the adaptive power supply voltage clamping circuit provided in this embodiment is basically the same as that in the first embodiment above, so details are not repeated here.

[0080] The difference is that in this embodiment, the preset condition that is satisfied between the target voltage V1 monitored by the clamping signal generating unit 100 and the voltage limit value corresponding to the target voltage V1 is: the difference between the target voltage V1 and the voltage limit value Value is less than 0. That is to say, the adaptive supply voltage clamping circuit in the second embodiment of the present disclosure is to realize the pull-up clamping of the target voltage V1, that is, when the target voltage V1 in the circuit changes to less than the voltage limit value, the control The target voltage V1 is pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com