Boiler coal slag clearing alarm method

A boiler and cinder technology, which is applied in the field of boiler cinder cleaning and alarming, can solve the problems of boiler economy and reliability reduction, and achieve the effect of improving self-adaptive ability, efficiency and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0027] In order to overcome the current problems of difficult detection and cleaning of boiler cinders, the present invention builds a method for cleaning and alarming boiler cinders. Each briquette target and each cinder target are distinguished, and based on the recognition result of the number of cinder targets, it is determined whether to perform a boiler cinder cleaning alarm. The boiler cinder cleaning alarm platform automatically completes the above-mentioned processing in an electronic manner.

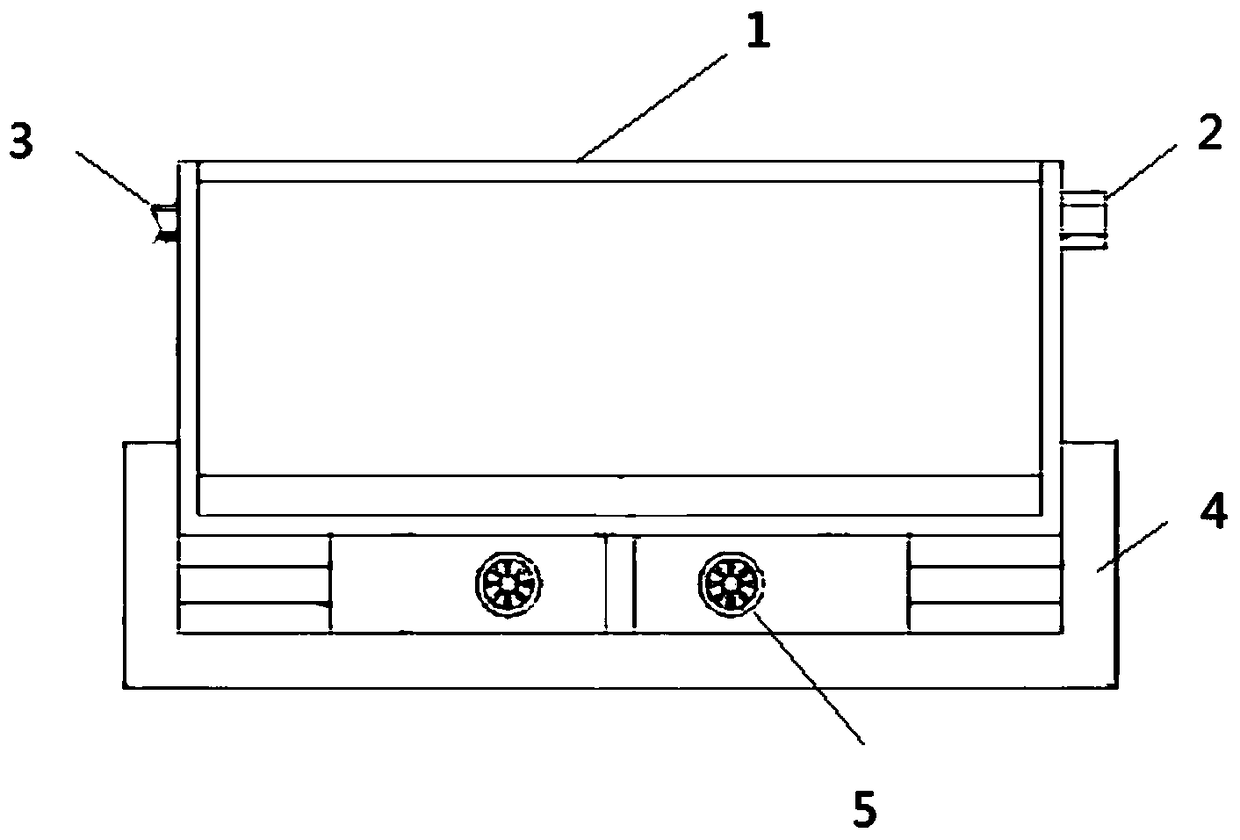

[0028] figure 1 It is a structural schematic diagram of a boiler cinder cleaning alarm platform according to an embodiment of the present invention, the platform includes a casing 1, a temperature control button 2, a water adding tank 3, a base 4, and left and right blast outlets 5;

[0029] The platform also includes:

[0030] The blowing operation swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com