Novel reactive power compensation cabinet based on electric energy quality control

A technology of power quality and power compensation, applied in reactive power compensation, reactive power adjustment/elimination/compensation, electrical components, etc., can solve problems such as inconvenient installation of power compensation devices, easy adhesion of dust to heat dissipation plates, and influence on the heat dissipation function of devices, etc. , to achieve the effect of convenient and convenient maintenance, increasing convenience and increasing convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

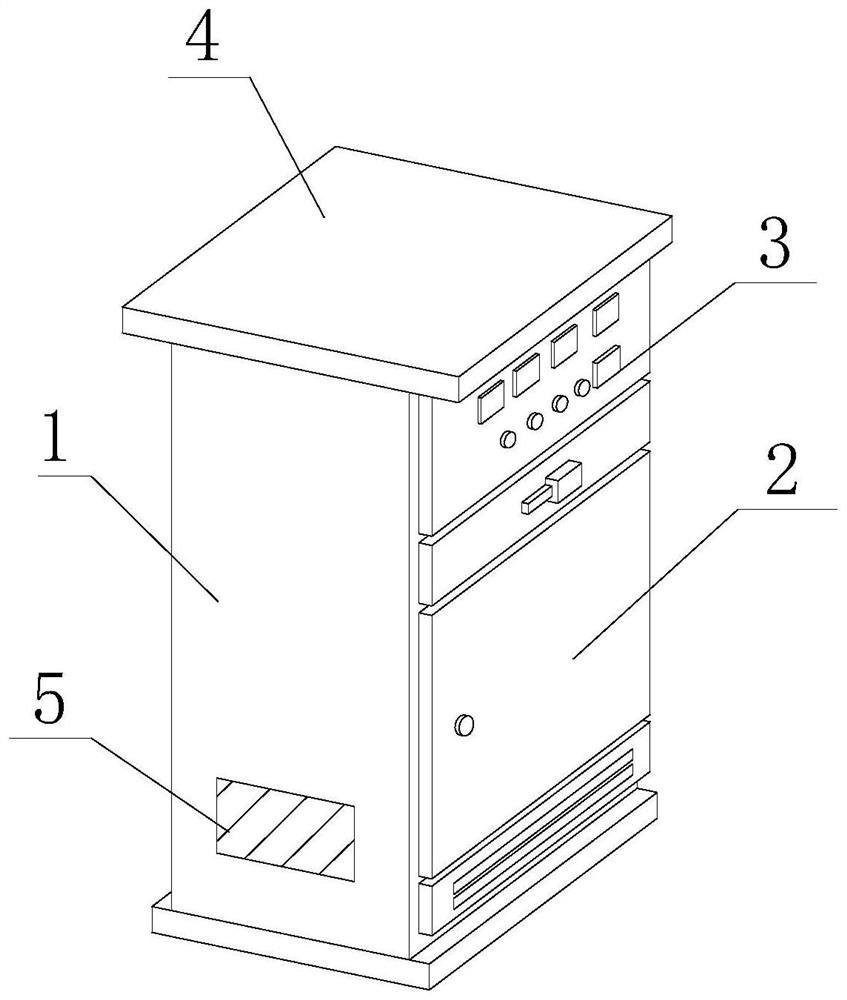

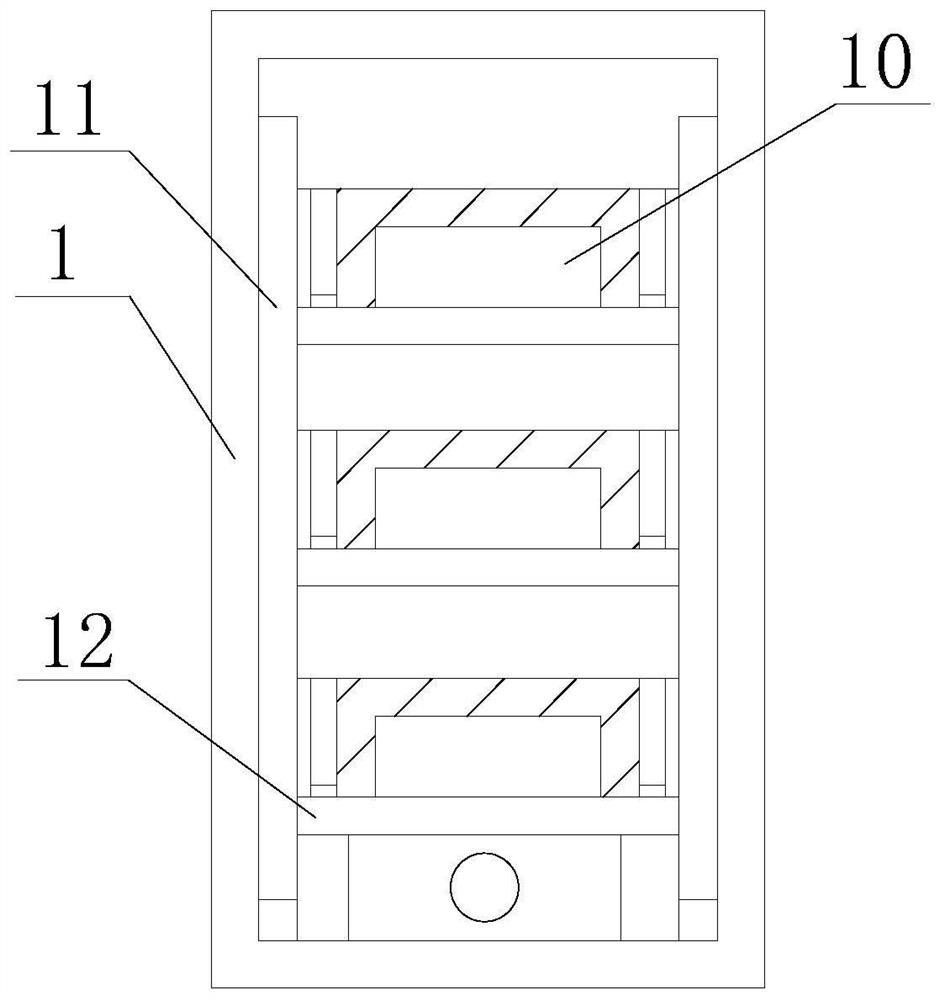

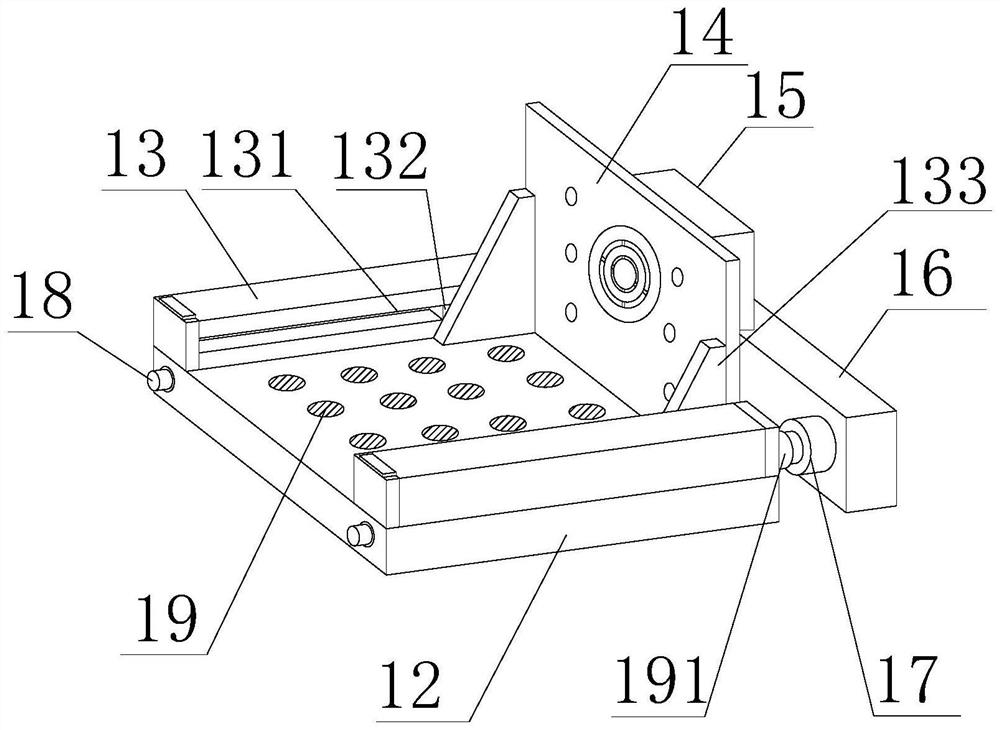

[0043] like Figure 1-8 As shown, the present invention provides a new type of non-power compensation cabinet based on power quality control, including a compensation cabinet body 1, a switch door 2, a control panel 3, a protective baffle 4 and a heat dissipation hole 5, and the side of the compensation cabinet body 1 is provided with a switch Door 2, the top of the switch door 2 is provided with a control panel 3, the top of the compensation cabinet body 1 is fixedly installed with a protective baffle 4, one side of the compensation cabinet body 1 is provided with a heat dissipation hole 5, and the interior of the compensation cabinet body 1 is fixed with a fixed Frame 11, the inner side of the fixed frame 11 is provided with a movable baffle 12, the interior of the movable baffle 12 is provided with electronic components 10, one side of the movable baffle 12 is provided with a telescopic rod 17, and the outer side of the telescopic rod 17 is provided with a clamping slot 171...

Embodiment 2

[0046] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a pressing column 18 is arranged inside the moving baffle 12, and a limit block 191 is arranged at the other end of the pressing column 18, and the inner side of the limit block 191 It is arranged on the outer side of one end of the telescopic rod 17 .

[0047] Telescopic columns 192 are fixedly installed on both sides of the inner cavity of the limiting block 191 , and a clamping block 193 is fixedly installed at one end of the telescopic column 192 . There is a lift rod 194 , one end of the lift rod 194 is provided with a moving ring 195 , and the inner side of the moving ring 195 is provided at the outer side of the telescopic column 192 .

[0048] The other end of the moving ring 195 is provided with a folding rod 1951 .

[0049] In this embodiment, by squeezing and moving the pressing column 18 , the limiting block 191 is driven to be sleeved ...

Embodiment 3

[0051] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a fixed column 13 is fixedly installed on the top of the movable baffle 12, and a chute 131 is opened on the inner side of the fixed column 13, and the inner side of the chute 131 is movable A slider 132 is installed.

[0052] A connecting inclined plate 133 is fixedly installed on the side of the slider 132 away from the chute 131 , a push plate 14 is fixedly connected to the side of the connecting inclined plate 133 , and a heat dissipation mechanism 15 is fixedly installed inside the push plate 14 .

[0053] In this embodiment, the sliding block 132 slides inside the chute 131, and then the sliding block 132 drives the connecting inclined plate 133 and the push plate 14 to slide, so as to push the electronic device to achieve the function of secondary pushing , it is convenient for the staff to carry out convenient disassembly, and the function o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com