Automatic sand pit leveling device for long jump sports

A technology for leveling devices and sand pools, applied in sports accessories, binding of skis, skating, etc., can solve problems such as loose sand pools, influence of athletes, cumbersome operation, etc., to achieve convenient handling, save measurement time, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

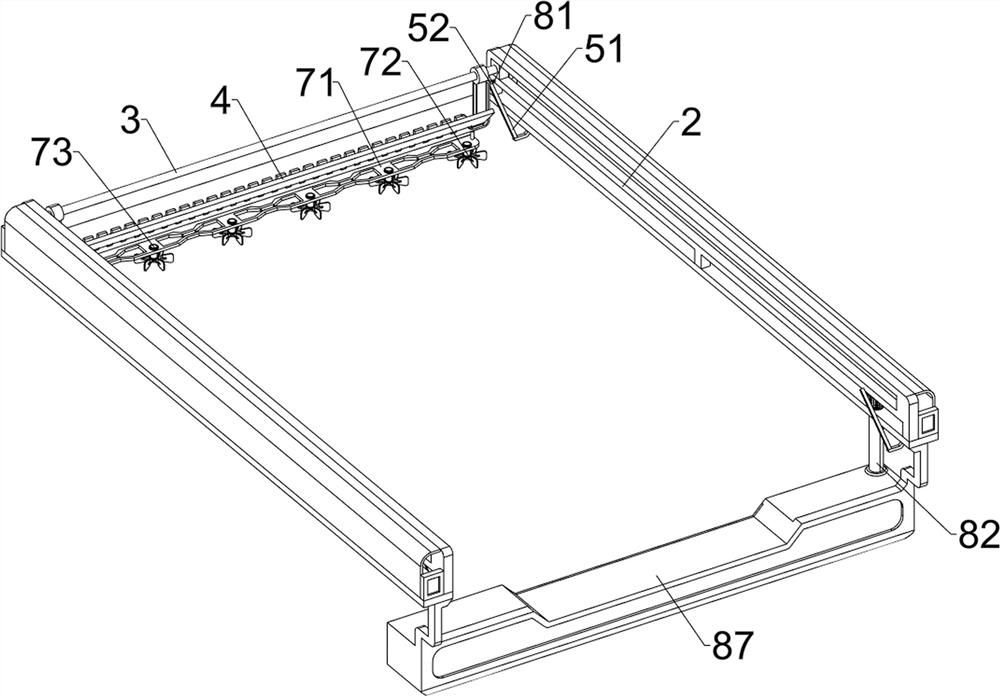

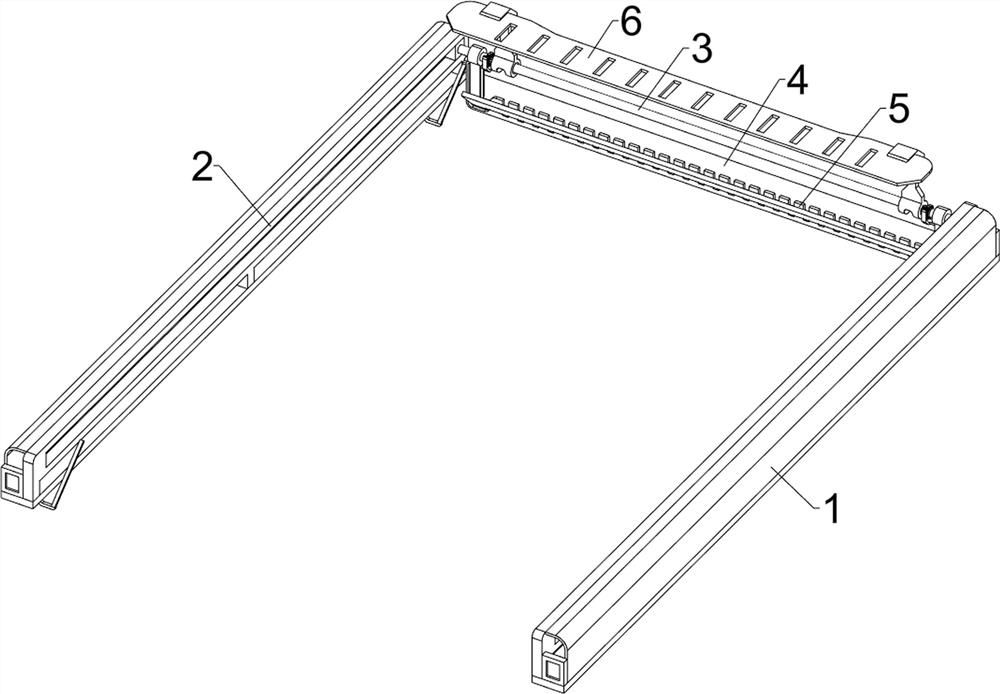

[0030] An automatic leveling device for sand pools for long jumping, such as Figure 1-2 As shown, it includes a fixed plate 1, a rodless cylinder 2, a sliding rod 3, a push frame 4, a reset mechanism 5 and a pull-back mechanism 6. The fixed plate 1 is provided with two left and right, and the two fixed plates 1 are close to each other. Rodless cylinders 2 are installed on the sides by means of screw connection, sliding rods 3 are slidably arranged between the rear parts of the two rodless cylinders 2, and the left and right parts of the sliding rods 3 are bolted for The push frame 4 for leveling the sand pool is provided with a reset mechanism 5 for stirring the sand pool, and the sliding rod 3 is provided with a pull-back mechanism 6 for pulling back the sand pool.

[0031] like image 3 As shown, the reset mechanism 5 includes a connecting rod 51, a contact block 52, a first connecting plate 53 and an oblique rod, the lower part of the push frame 4 is slidably provided wit...

Embodiment 2

[0035] On the basis of Example 1, as figure 1 and Figure 4 As shown, it also includes a sand loosening mechanism 7 for loosening the sand tank. The sand loosening mechanism 7 includes a support frame 71, a stirring frame 72 and a motor 73. The bottom side of the first connecting plate 53 is bolted with a support frame 71. The support frame Five motors 73 are installed on the lower part of the motor 71 by means of screw connection evenly spaced apart, and a stirring frame 72 is connected to the output shaft of the motors 73 .

[0036] Initially, the stirring frame 72 is inside the sand pool, the operator starts the motor 73, the output shaft of the motor 73 will drive the stirring frame 72 to rotate, and the stirring frame 72 will agitate the sand pool, so as to loosen the inside of the sand pool and cooperate with The first connecting plate 53 can further prevent the hardening of the sand pool from causing damage to the players, and then the downward movement of the first co...

Embodiment 3

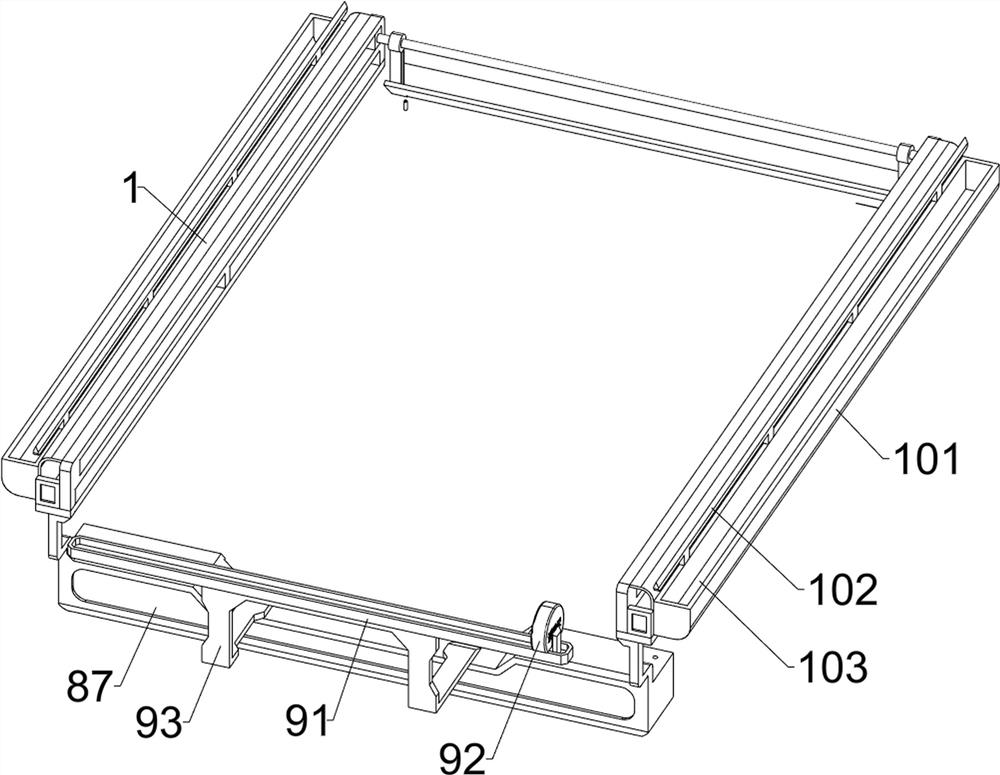

[0038] On the basis of Example 2, as figure 1 , Figure 5 and Image 6 As shown, it also includes a timing mechanism 8 for timing sand loosening. The timing mechanism 8 includes a tooth block 81, an automatic reset switch 83, a connecting shaft 84, a contact rod 85, a second gear 86, a connecting frame 87, a support base 88 and A torsion spring 89, a connecting frame 87 is welded between the front lower sides of the two fixing plates 1, a support seat 88 is bolted on the right side of the inner bottom of the connecting frame 87, and the right rear side of the support seat 88 is installed with an electric motor 73. There is an automatic reset switch 83 connected to each other, a connecting shaft 84 is rotatably provided between the front part of the right fixing plate 1 and the connecting frame 87, and the lower part of the connecting shaft 84 is connected with a contact rod 85 for pressing the automatic reset switch 83. The contact rod 85 and the connecting frame 87 are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com