Polyester synthesis vacuum system and online replacement method of sealing element of polyester synthesis vacuum system

A technology of vacuum system and seal, applied in the direction of using atmospheric pressure to chemically change substances, chemical instruments and methods, components of pressure vessels, etc., can solve the problems of lost production capacity, long parking time, energy loss, etc. Achieve the effect of increasing the replacement speed, improving the sealing effect and reducing heat energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

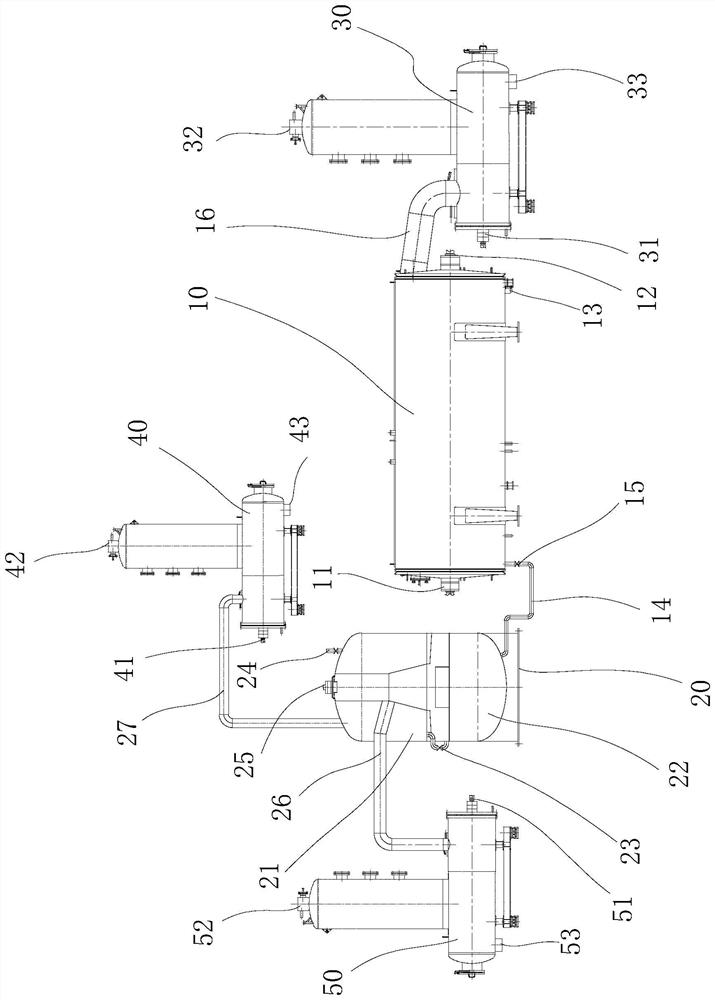

[0025] like figure 1 As shown, the polyester synthesis vacuum system of this embodiment is a four-pot polyester system, including a first esterification reactor (not shown in the figure), a second esterification reactor (not shown in the figure), a pre-polycondensation reaction The reactor 20, the final polymerization reactor 10, the pre-polycondensation reactor 20 is a multi-layer reactor, and the pre-polycondensation reactor 20 specifically includes a pre-polycondensation reactor upper chamber 21 and a pre-polycondensation reactor lower chamber 22 that are isolated from each other. The pre-polycondensation reaction The upper chamber 21 and the lower chamber 22 of the pre-polycondensation reactor are communicated through the pre-polycondensation communication pipe 23, and the pre-polycondensation communication pipe 23 is provided with a control valve for controlling the on-off;

[0026] The top of the prepolycondensation reactor 20 is provided with a prepolycondensation feed ...

Embodiment 2

[0033] As in the polyester synthesis vacuum system in Example 1, the method for on-line replacement of its seals includes the following steps: first, close the feed valve on the pre-polycondensation feed port 24, stop feeding into the pre-polycondensation reactor 20, but pre-polycondensation The heat medium of the polycondensation reactor 20 and the final polymerization reactor 10 is continuously supplied, so that the pre-polycondensation reaction in the pre-polycondensation reactor 20 and the final polymerization reaction in the final polymerization reactor 10 continue to proceed, and the finished product is continuously discharged, so that the The materials in the pre-polycondensation reactor 20 and the final polymerization reactor 10 continue to decrease until they are basically empty, and then the inert gas nitrogen is filled into the pre-polycondensation reactor 20 and the final polymerization reactor 10 until the pressure in the final polymerization reactor 10 is reached. ...

Embodiment 3

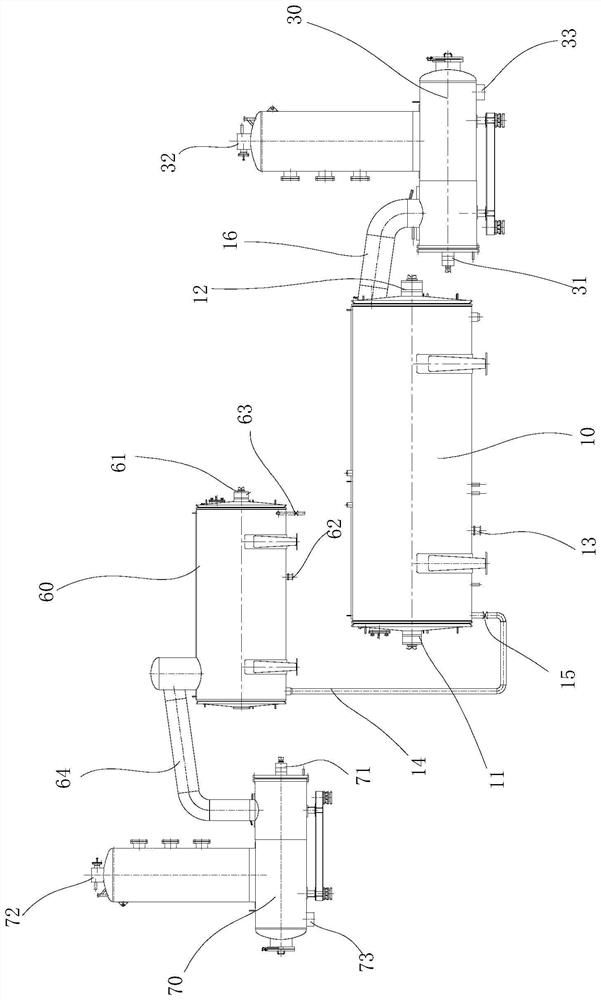

[0036] like figure 2 As shown, the polyester synthesis vacuum system of this embodiment is a five-tank polyester system, including a first esterification reactor (not shown in the figure) and a second esterification reactor (not shown in the figure) serially connected in series. , the first pre-polycondensation reactor (not shown in the figure), the second pre-polycondensation reactor 60, the final polymerization reactor 10,

[0037] Both ends of the final polymerization reactor 10 are respectively provided with a feed end mechanical seal 11 and a discharge end mechanical seal 12, and the bottom of the final polymerization reactor 10 is provided with a discharge port 13;

[0038] The final polymerization reactor 10 is communicated with the final polymerization scraper condenser 30 through the final polymerization outlet pipe 16. One end of the final polymerization scraper condenser 30 is provided with a first mechanical seal 31, and the top of the final polymerization scraper...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap