Full-cooling type gas static pressure main shaft

A gas static pressure and cooling technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of limited heat dissipation, unstable performance, and decreased processing accuracy, so as to achieve good control and increase stability , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following embodiments are intended to illustrate the present invention, but are not intended to limit the scope of the present invention.

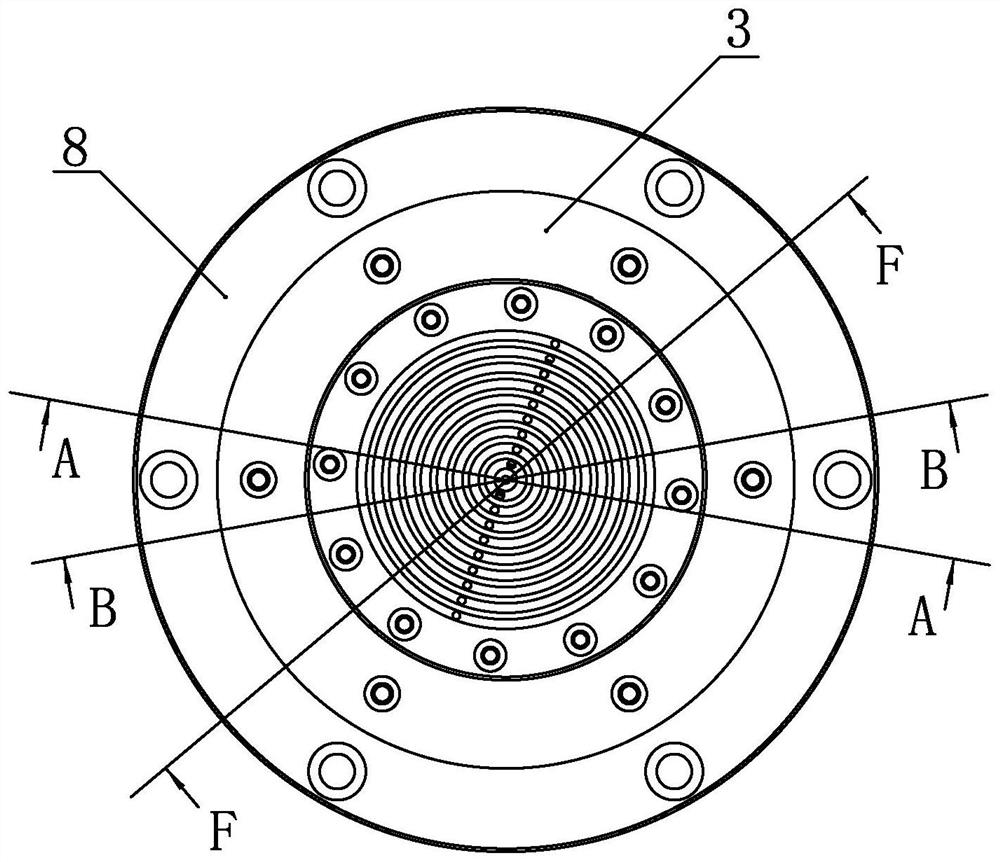

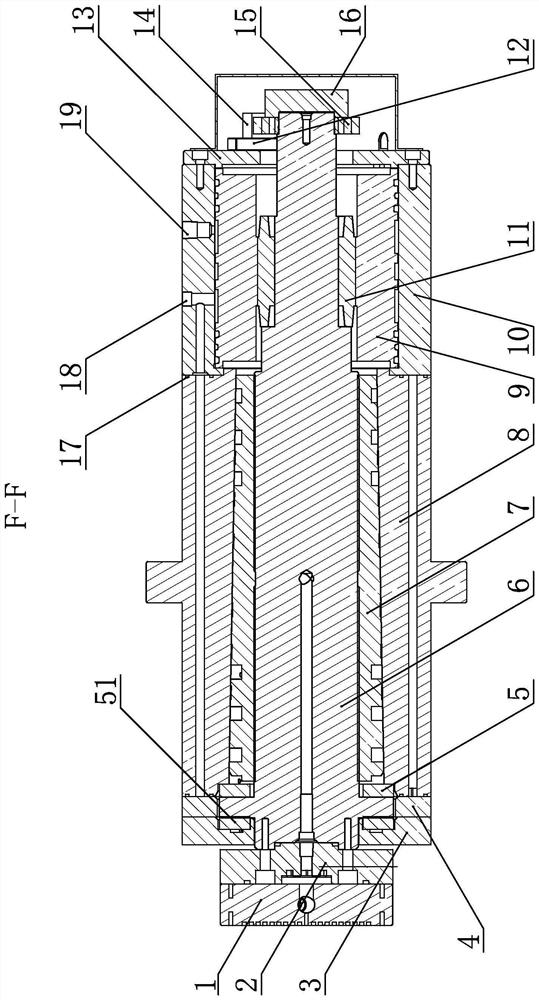

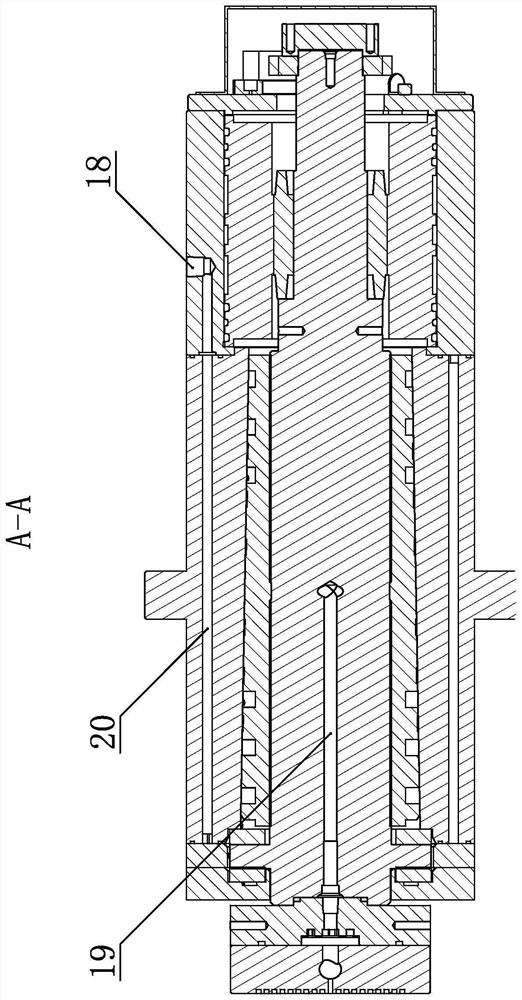

[0028] as Figure 1-Figure 4 As shown, the present invention fully cooled gas hydrostatic spindle comprises a spindle body 6, the external part of the spindle body 6 is provided with a spindle sleeve 8, the front surface of the spindle body 6 is equipped with a suction cup 1, the rear of the spindle body 6 is equipped with a spindle motor.

[0029] Between the spindle body 6 and the spindle sleeve 8 is provided graphite long bushing 7, the length of the graphite major bushing 7 is slightly shorter than the spindle sleeve 8. Graphite long shaft sleeve 7 is provided with a circular groove on the outer ring, and the annular groove is located at the front and rear of the graphite long shaft sleeve 7, respectively. The multi-channel annular groove forms a gas path channel, and the gap between the graphite long shaft sleeve 7 and the spind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com