Automatic glaze water preparation and production system

A production system and automatic preparation technology, applied in the production of ceramic materials, manufacturing tools, ceramic molding machines, etc., can solve the problems of physical consumption, lack of integration, complexity, etc., to reduce errors, ensure accuracy, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

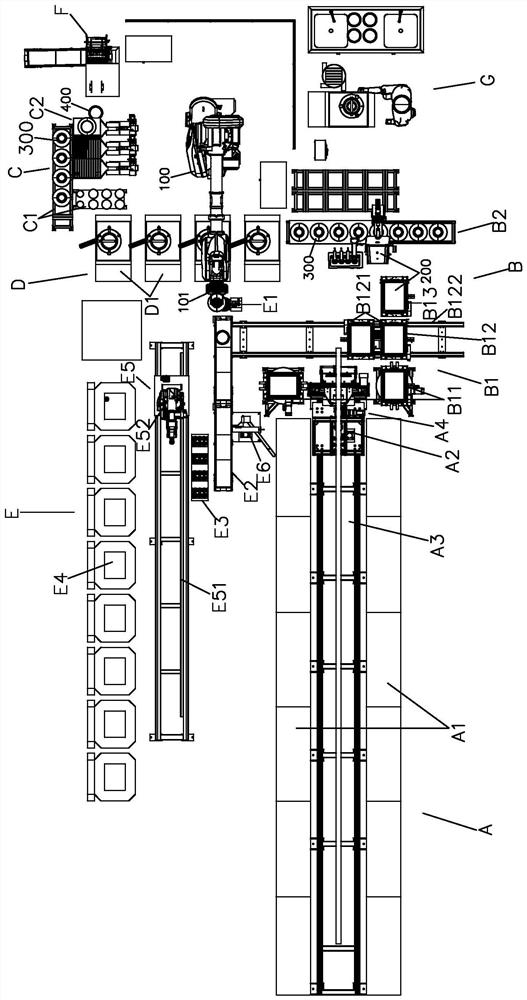

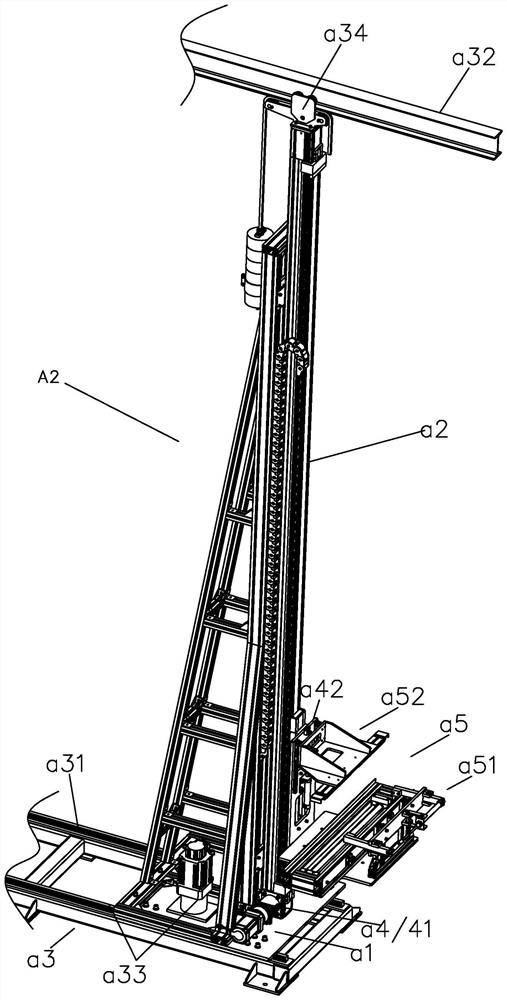

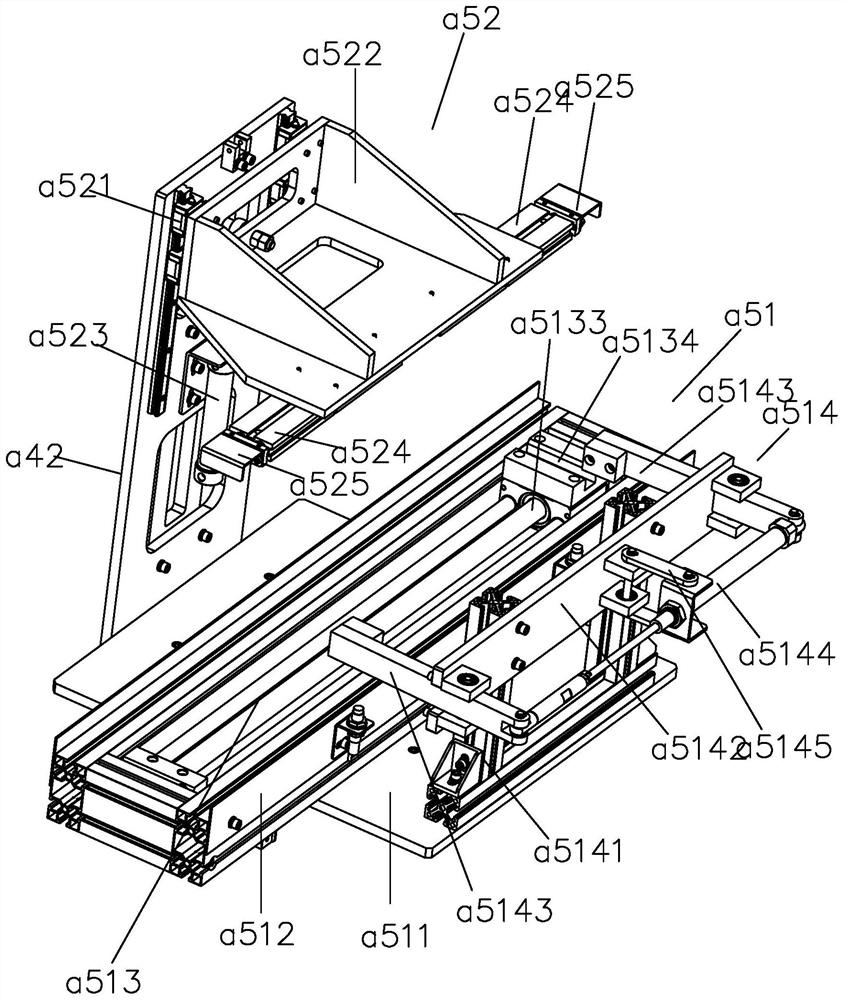

[0061] A production system for automatic preparation of glaze water disclosed in this embodiment, such as figure 1 and Figure 13 As shown, it includes inventory area A, preparation area B, ball mill work area D, cleaning and discharging area C, firing area E, automatic packaging area F, manual operation area G, multi-axis robotic arm 100 and control system (not shown in the figure). It can be seen that the control system is used to control the operation of the entire system, so it is mainly the mechanical control of each area and equipment according to the glaze water preparation and production process, mainly the part of electrical control and control program).

[0062] The storage area A is used to store the raw materials for preparing glaze water;

[0063] Described preparation area B is used for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com