PVC pipeline forming extruder capable of being rapidly cooled

A rapid cooling and extruder technology, applied in the direction of cooling/ventilation devices, electromechanical devices, lighting and heating equipment, etc., can solve the problems of waste, inconvenient reuse of extruder heat, etc., and achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

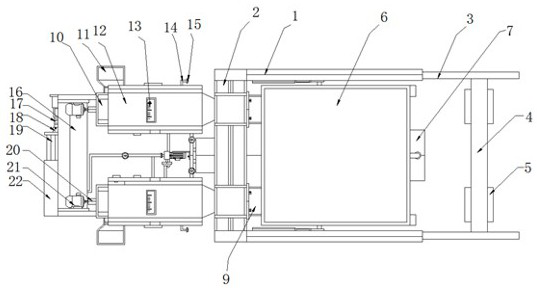

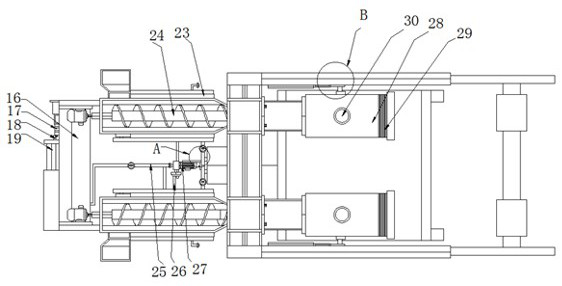

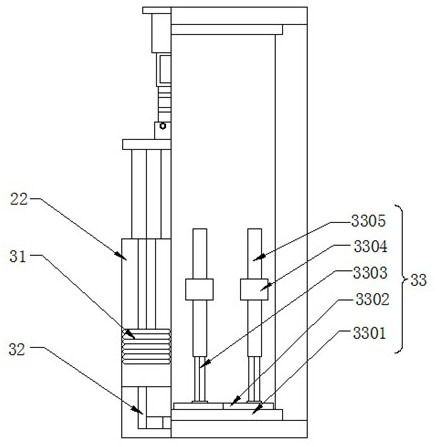

[0031] see Figure 1 to Figure 8 , the present invention provides a technical solution: an extruder capable of rapidly cooling PVC pipes, including a connecting frame 1, a connecting plate 2, a built-in adjustment rod 3, a longitudinal rod 4, an auxiliary chamber 5, a first water tank 6, a side Frame 7, transfer block 8, molding cavity 9, extrusion barrel 10, discharge trough 11, external cavity plate 12, thermometer 13, lead-out pipe 14, fastening cover 15, fixed cavity 16, first hydraulic air rod 17 , fixed block 18, push rod 19, connecting shaft 20, motor 21, connecting bottom cavity 22, heating plate 23, threaded rod 24, first connecting pipe 25, second connecting pipe 26, first water pump 27, cooling bucket 28, Threaded block 29, assembly groove 30, rubber bottom pad 31, thin tube 32, adjustment assembly 33, connecting bottom plate 3301, built-in air bag 3302, movable inner rod 3303, fixed sleeve plate 3304, external cavity 3305, installation groove 34, second Water pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com