Textile tensioner based on adjusting device

A technology of tensioner and tension, which is applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve problems affecting processing production, yarn winding problems, and yarn breakage, so as to improve production and processing Efficiency and quality, prevention of thread breakage or winding problems, effect of ensuring yarn tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

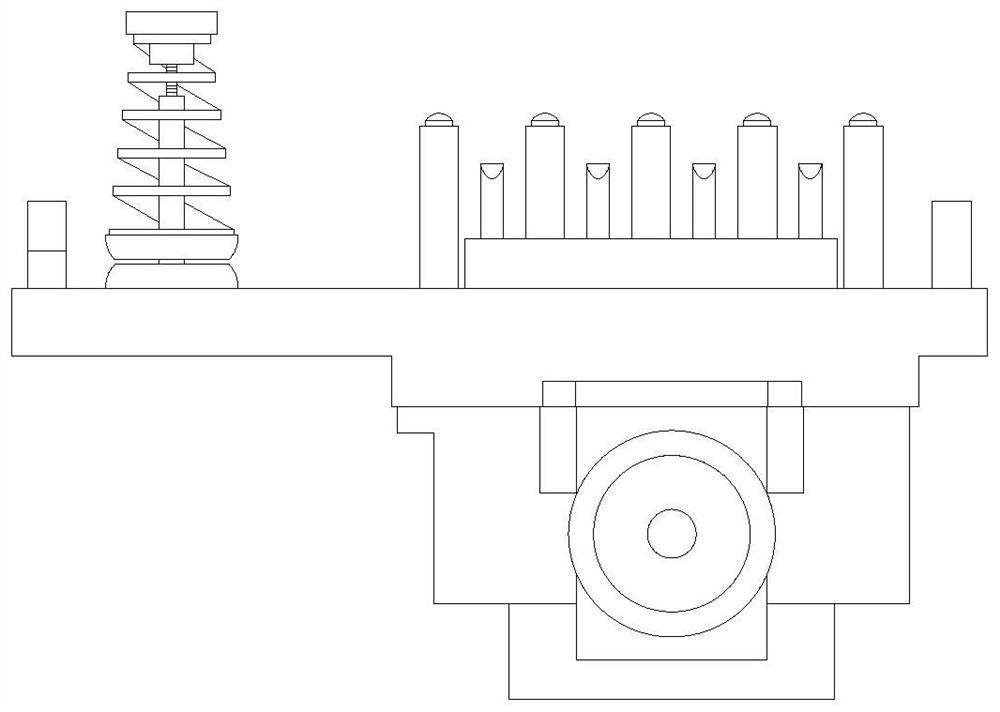

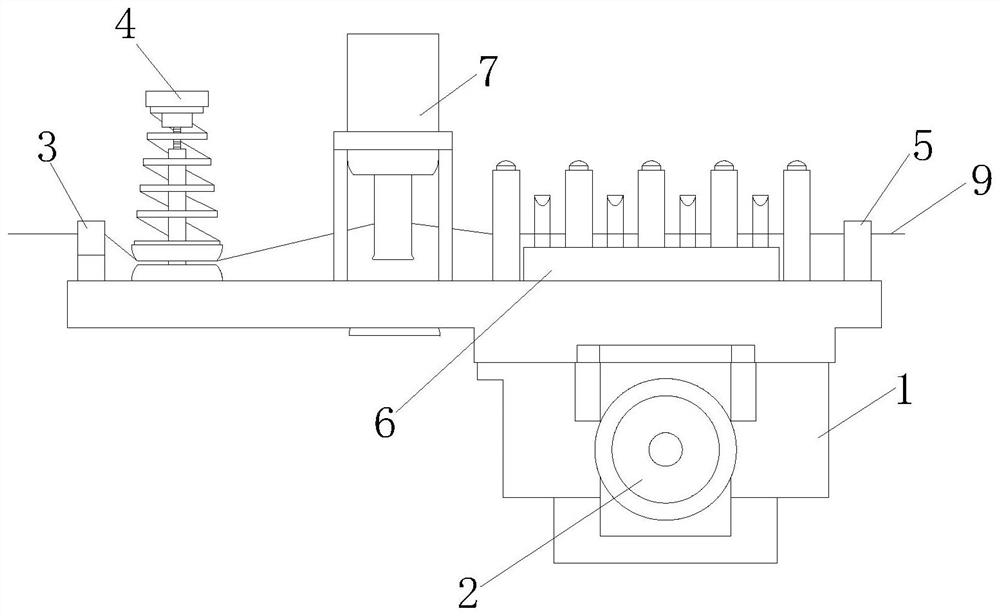

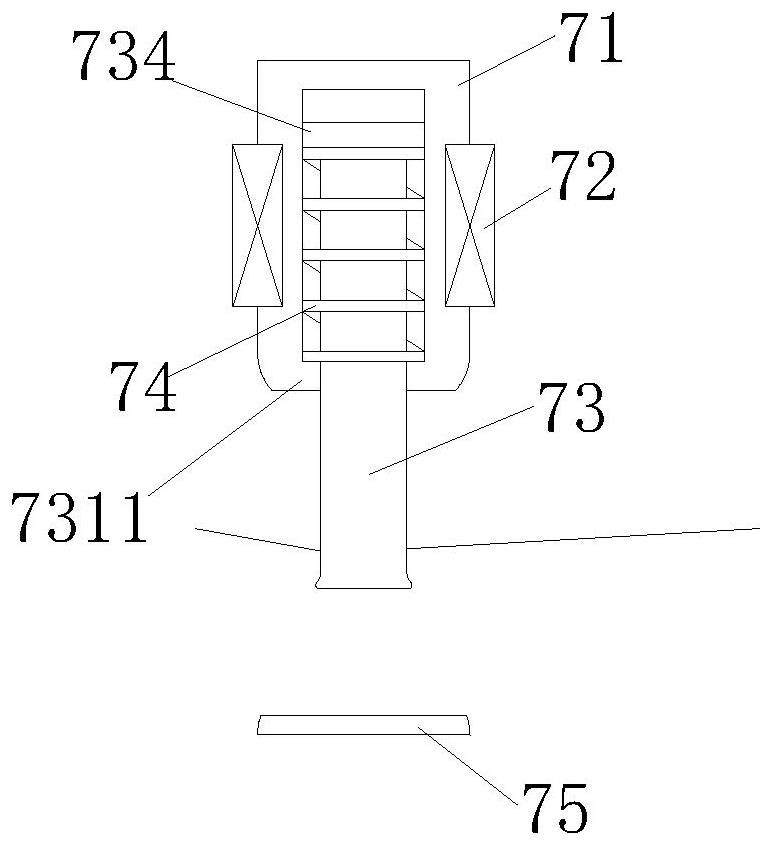

Image

Examples

Embodiment 1

[0028] Embodiment 1, referring to the accompanying drawings, a method for adjusting yarn tension, comprising: adopting a combined adjustment method of manual adjustment and automatic adjustment;

[0029] Preset yarn tension value P 1 , preset real-time yarn tension values P and P 1 The allowable range of the difference is ΔP 允 ;

[0030] Measure the real-time yarn tension value P, and determine the real-time yarn tension value P and the preset yarn tension value P 1 The difference between , set as ΔP 差 , judge ΔP 差 Is it at ΔP 允 range, if ΔP 差 at ΔP 允 Within the range, use manual adjustment to adjust the yarn tension, if ΔP 差 not at ΔP 允 Within the range, the automatic adjustment method is used to adjust the yarn tension.

[0031] Real-time yarn tension value P and preset yarn tension value P 1 The difference ΔP 差 not within the allowable difference ΔP 允 Within the range, there are two situations. One is that the yarn tension is too large. If the yarn tension is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com