Glass processing technology

A processing technology, glass technology, applied in glass production, glass cutting device, glass manufacturing equipment, etc., can solve the problems of reducing glass processing efficiency and inability to achieve high-efficiency cutting, so as to improve cutting and breaking efficiency, improve operating performance, and structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

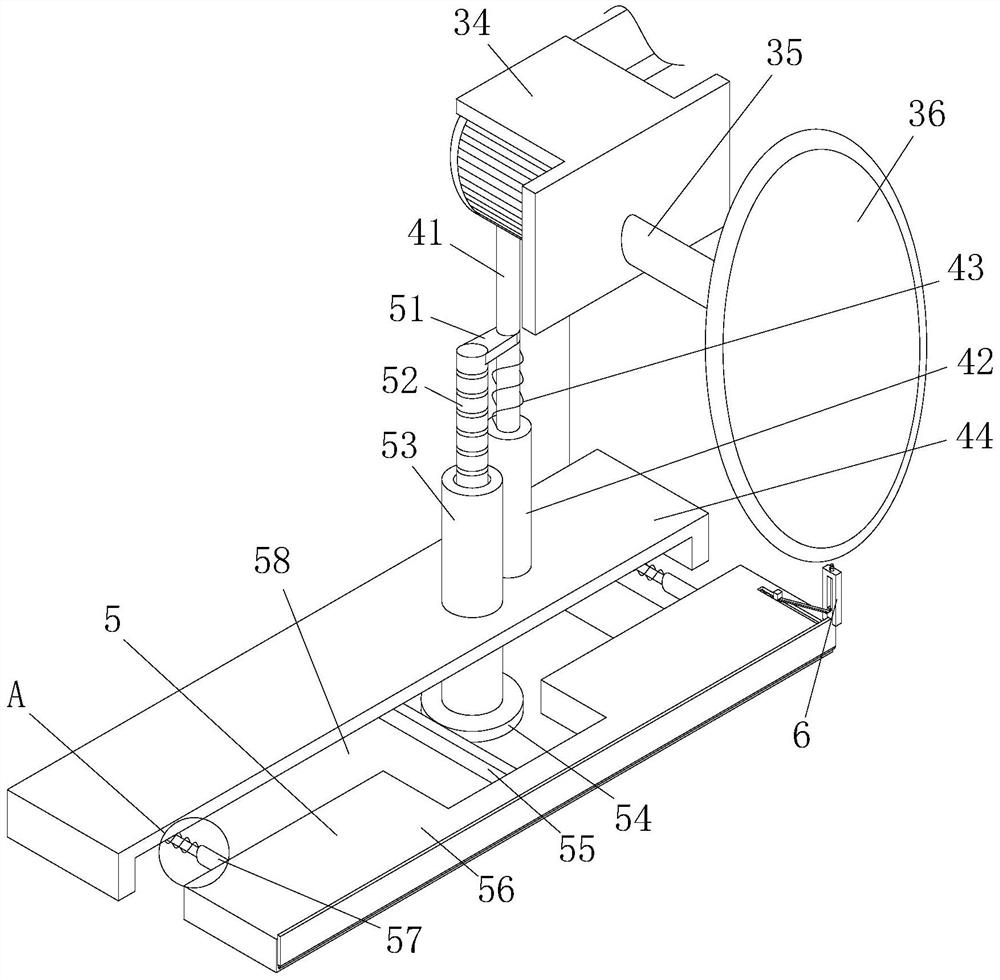

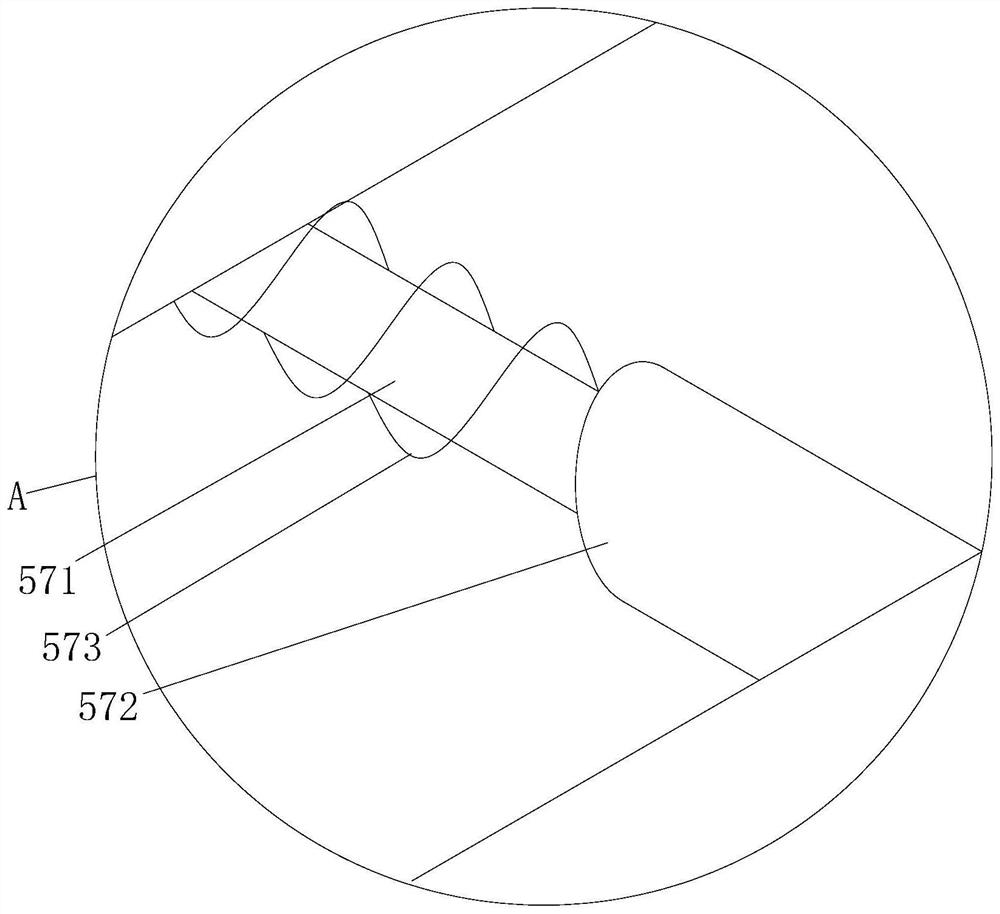

[0037] Attached below Figure 1-4 The present invention is further described with examples:

[0038] A glass processing technology, comprising the following steps:

[0039] S1 material preparation: prepare colorless glass substrate raw materials;

[0040] S2 cutting material: the colorless glass substrate raw material is cut into a preset shape glass wool by a cutting device;

[0041] S3 processing: the glass wool is subjected to edge grinding and drilling processing, and the processed glass wool is pulled into the flowing water;

[0042] S4 processing: the glass wool in step S3 enters the washing machine in the running water for processing;

[0043] S5 drying: put the glass wool after step S4 into a drying furnace to dry for use;

[0044] S6 configuration dye: configure a variety of dyes of specific colors to form dyes of different colors;

[0045] S7 printing pattern: add the configured dye to the screen printing machine to form a customized pattern, and print the custo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com