Novel resin not easy to wear and preparation process thereof

A resin, a new technology, applied in the field of new resin and its preparation process, can solve the problems of insignificant acid and alkali corrosion resistance, non-scratch-resistant outer layer, inconvenient cutting and taking, etc., to save manpower and material resources, avoid surface moisture, non-discrete effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

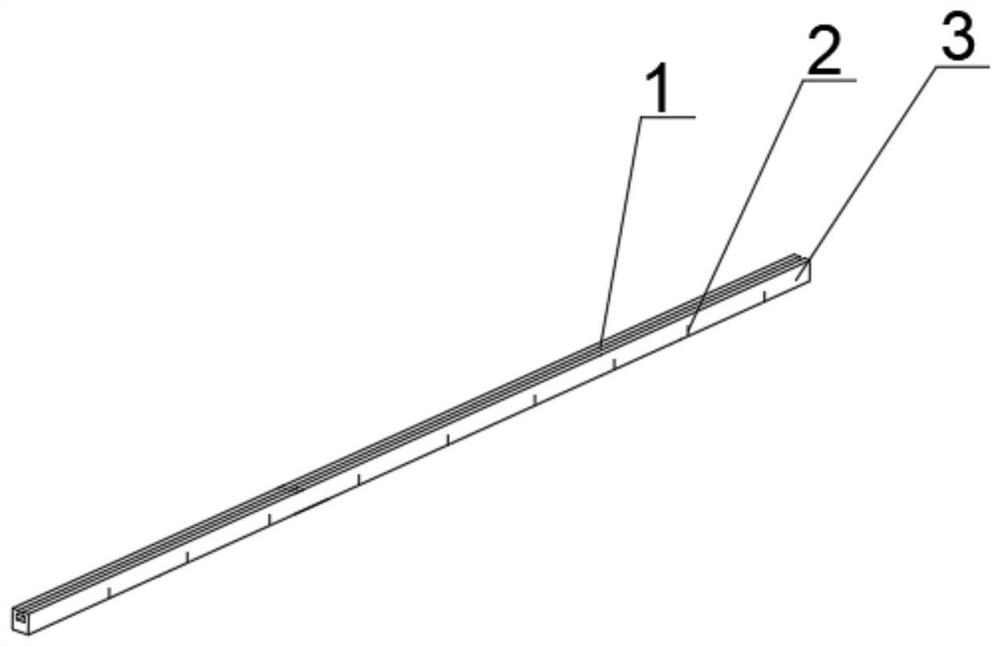

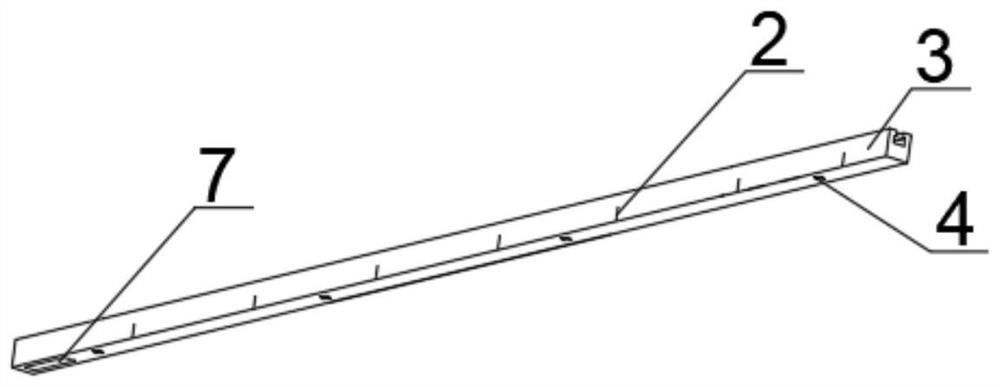

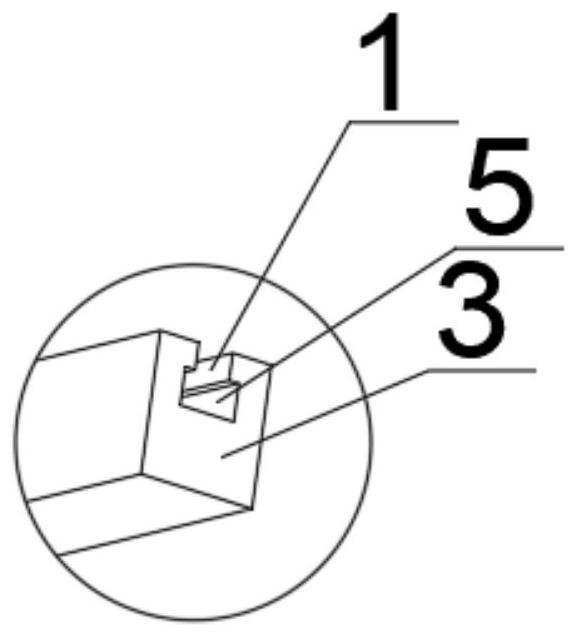

[0025] like Figure 1-4 As shown, a new type of resin that is not easy to wear, comprises strip resin 3, distance marking 2, pressing groove 5 and closing notch 1, and one side of the strip resin 3 is provided with distance marking 2 at equal distances, so The strip-shaped resin 3 is provided with a pressure groove 5 , and the top of the pressure groove 5 is provided with a notch 1 .

[0026] Wherein, the receiving groove 1 and the pressing groove 5 are communicated with each other, and the bottom end of the strip resin 3 is provided with an identification spray code 7 .

[0027] Wherein, there are separation holes 6 equidistantly opened at 2 places from the marking line.

[0028] Wherein, the bottom of the strip resin 3 is provided with ventilation holes 4 at equal distances.

[0029] A kind of novel resin that is not easy to wear, the concrete preparation method steps are as follows:

[0030] Step 1: Weigh the corresponding parts by weight of 35.5 parts by weight of polyl...

Embodiment 2

[0036] like Figure 1-4 As shown, a new type of resin that is not easy to wear, comprises strip resin 3, distance marking 2, pressing groove 5 and closing notch 1, and one side of the strip resin 3 is provided with distance marking 2 at equal distances, so The strip-shaped resin 3 is provided with a pressure groove 5 , and the top of the pressure groove 5 is provided with a notch 1 .

[0037] Wherein, the receiving groove 1 and the pressing groove 5 are communicated with each other, and the bottom end of the strip resin 3 is provided with an identification spray code 7 .

[0038] Wherein, there are separation holes 6 equidistantly opened at 2 places from the marking line.

[0039] Wherein, the bottom of the strip resin 3 is provided with ventilation holes 4 at equal distances.

[0040] A kind of novel resin that is not easy to wear, the concrete preparation method steps are as follows:

[0041] Step 1: Weigh the corresponding parts by weight of 36.9 parts by weight of polyl...

Embodiment 3

[0047] like Figure 1-4 As shown, a new type of resin that is not easy to wear, comprises strip resin 3, distance marking 2, pressing groove 5 and closing notch 1, and one side of the strip resin 3 is provided with distance marking 2 at equal distances, so The strip-shaped resin 3 is provided with a pressure groove 5 , and the top of the pressure groove 5 is provided with a notch 1 .

[0048]Wherein; the groove 1 and the pressure groove 5 are communicated with each other, and the bottom end of the strip resin 3 is provided with an identification spray code 7;

[0049] Wherein; the distance marking line 2 is equidistantly provided with separation holes 6; the separation hole 6 is made on one side of the strip resin 3 to form the distance marking line 2, which is convenient for taking the strip resin 3 at different distances, and it is convenient to separate the strip resin 3. 3. Manually cut according to the length used to save manpower and material resources.

[0050] Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com