Railway turnout snow melting system and method based on laser surface heat treatment

A technology of surface heat treatment and turnout, applied in the field of railway construction, can solve the problems of high power consumption, high project cost, difficult daily operation and maintenance, etc., and achieve the effect of small quantity and low project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

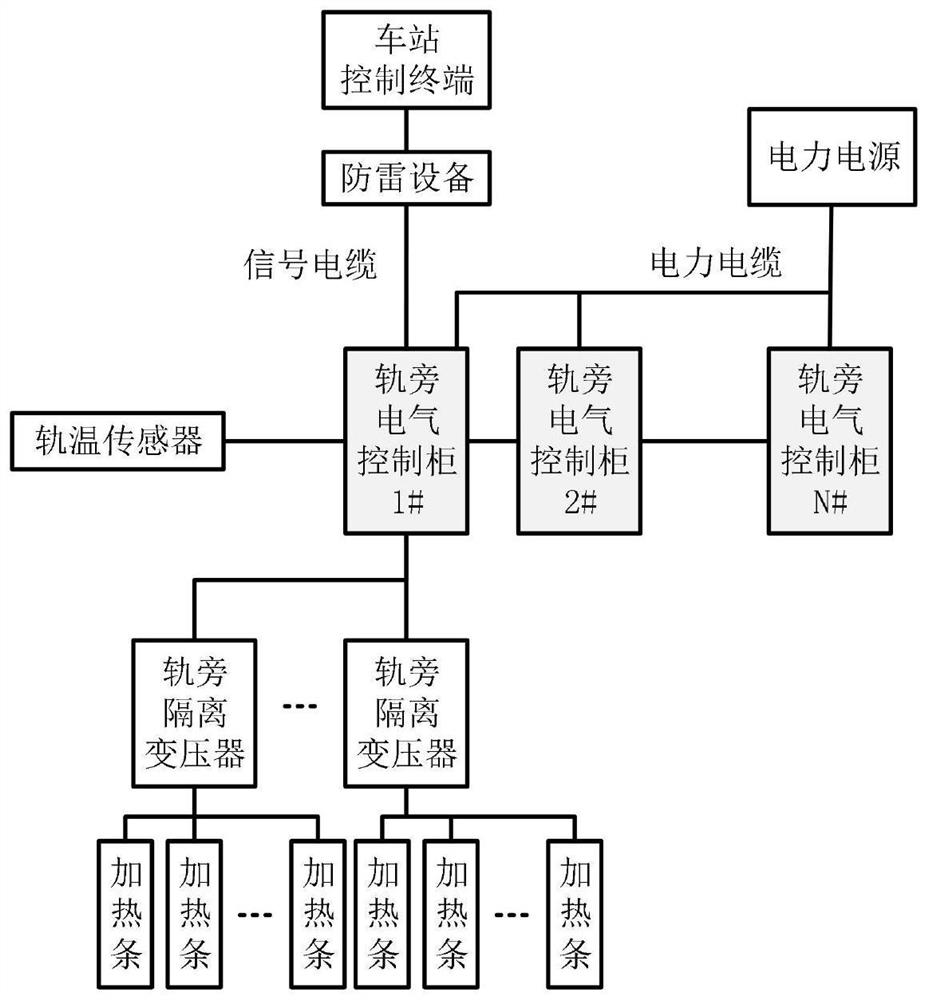

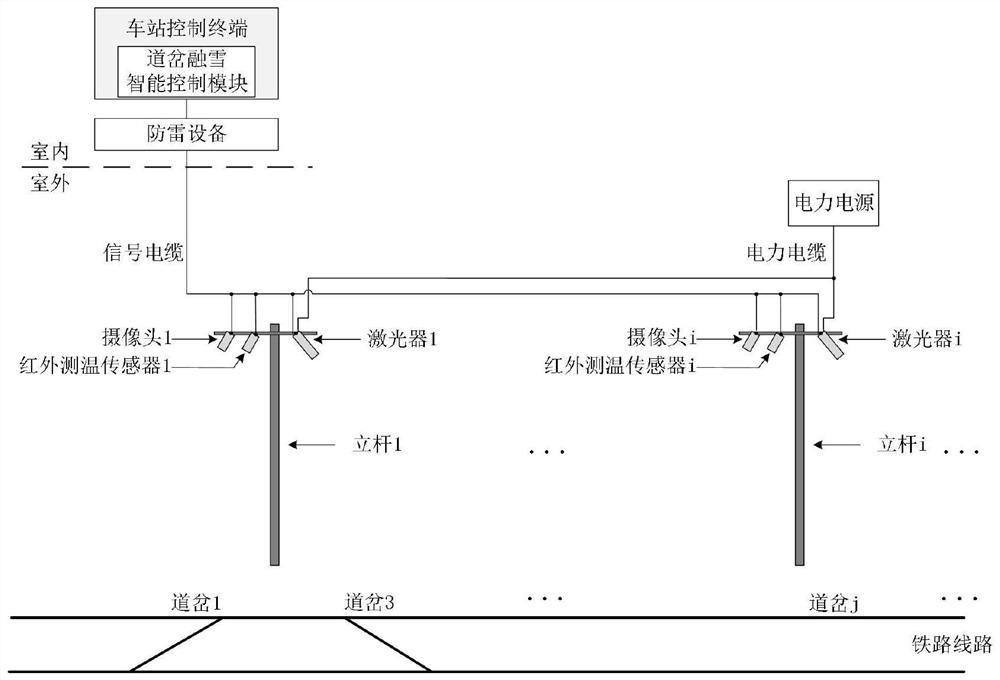

[0025] see figure 2 , an embodiment of the present invention provides a railway turnout snow melting system based on laser surface heat treatment, including a laser and an environmental detection device, the laser and the environmental detection device are connected to a control terminal, and the environmental detection device is used to transmit a detection signal to the control A terminal, the control terminal is used for judging the ice and snow coverage of the railway switch according to the detection signal of the environment detection device, and outputting a control signal to the laser, so as to control the laser to perform laser surface heat treatment on the surrounding switch.

[0026] Further, the environment detection device includes a camera, and the camera is used to photograph the ice and snow coverage on the surrounding switch, and send the photographed picture to the control terminal, and the control terminal judges through image recognition whether the switch ...

Embodiment 2

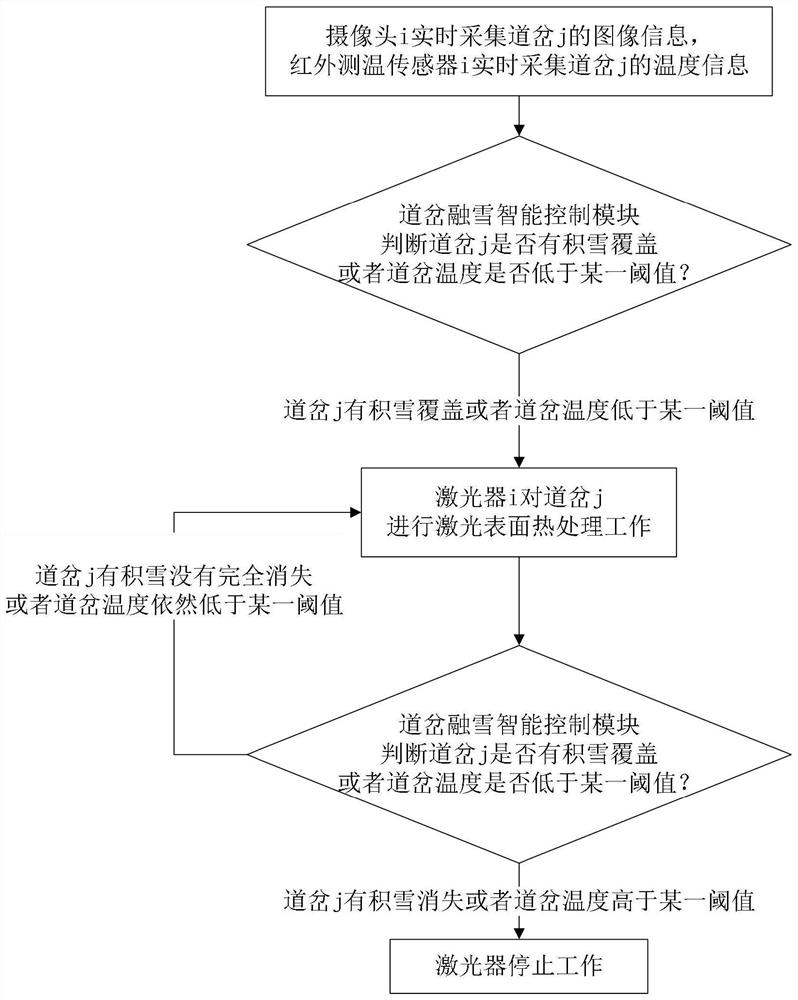

[0037] see image 3 , the embodiment of the present invention discloses a method for melting snow of railway turnouts based on laser surface heat treatment, comprising the following steps:

[0038] The image information of the surrounding switch is captured in real time through the camera, and the image is transmitted to the control terminal;

[0039] The control terminal judges whether the turnout picture captured by the camera is covered with ice and snow through the image recognition algorithm. If it is detected that the turnout is covered with ice and snow, it controls the laser to start working;

[0040] The control terminal recognizes and accurately locates the range of the laser scanning switch through the image, and controls the laser to align the switch to scan and irradiate a certain area of the switch, so that the temperature of the switch increases and the snow melts;

[0041] If the control terminal detects that the ice and snow on the switch is melted, the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com