Spherical rotating anchorage device and retaining wall anchoring structure

A spherical and anchoring technology, applied in underwater structures, infrastructure engineering, sheet pile walls, etc., can solve the problems of inability to form external anchors, time required for consolidation, damage to existing structures, etc. The effect of low cost and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Project brief: There is an upright rock slope project whose stability does not meet the requirements of the specification, and slope support is required. After analysis, the prefabricated bolt support scheme is adopted to form the retaining wall anchoring structure.

[0024] Implementation steps:

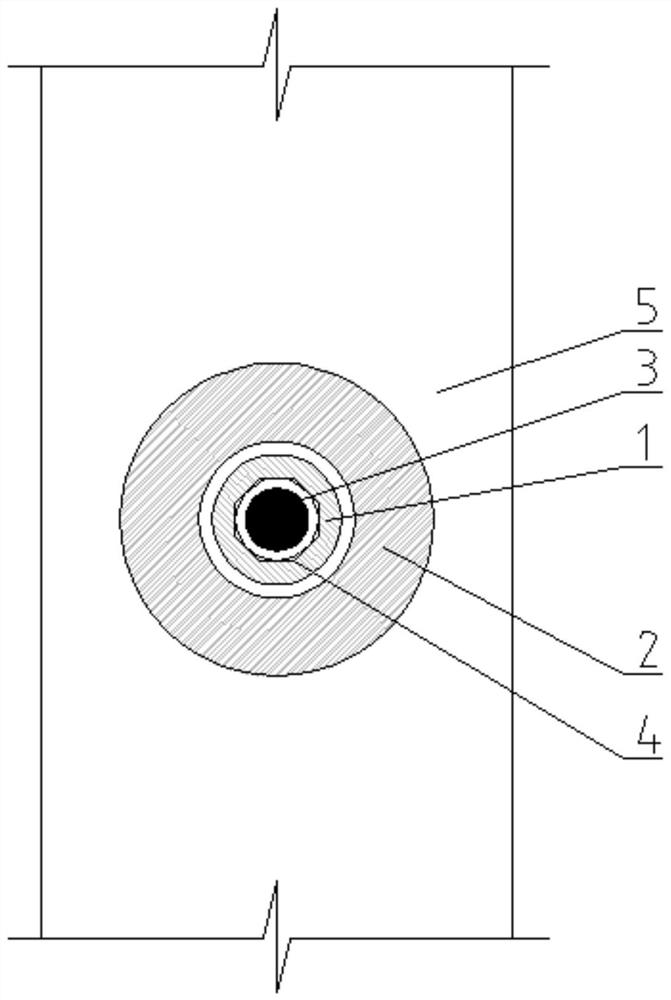

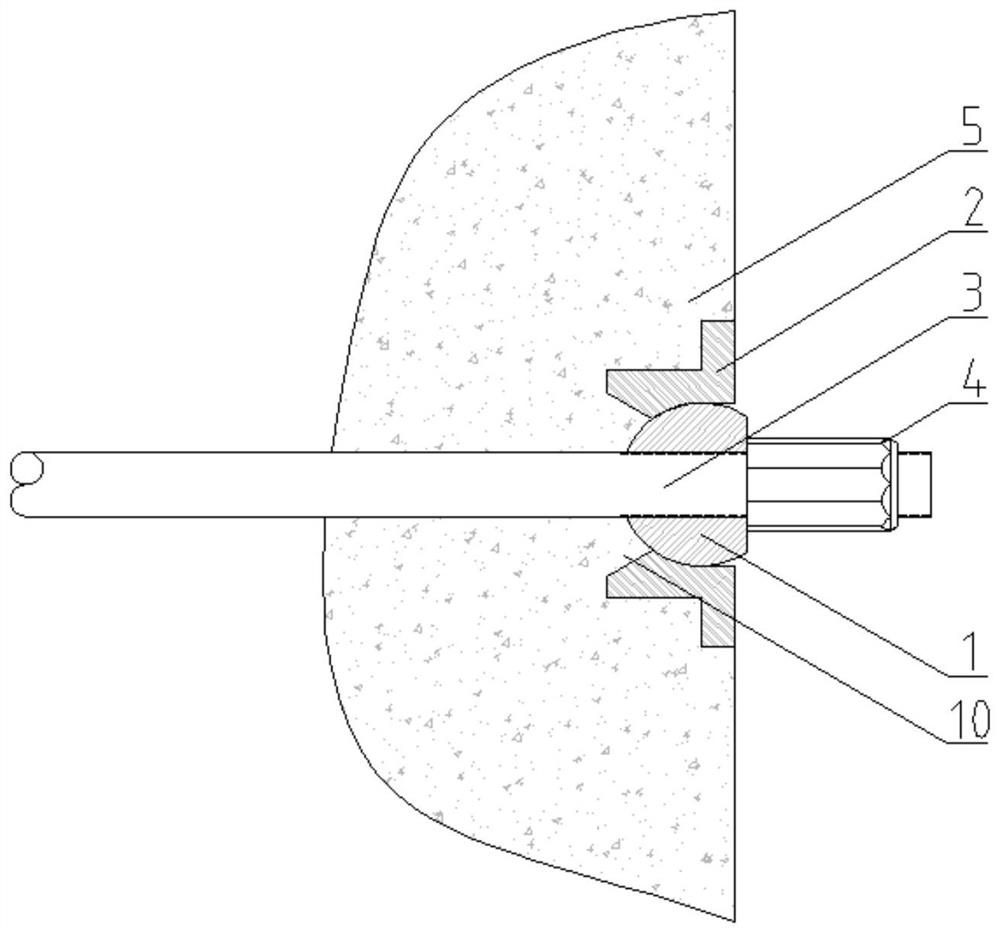

[0025] Step 11, first prefabricate the concrete structure 5 (point anchor block) according to the design, pre-embed the hemispherical anchor cup 2 in the concrete structure 5, and set the reserved holes 6 for the concrete members in the concrete structure 5 according to the design, and the concrete structure 5 maintenance spare;

[0026] Step 12, construct the anchor rod 3 according to the design, and carry out the grouting of the anchor hole;

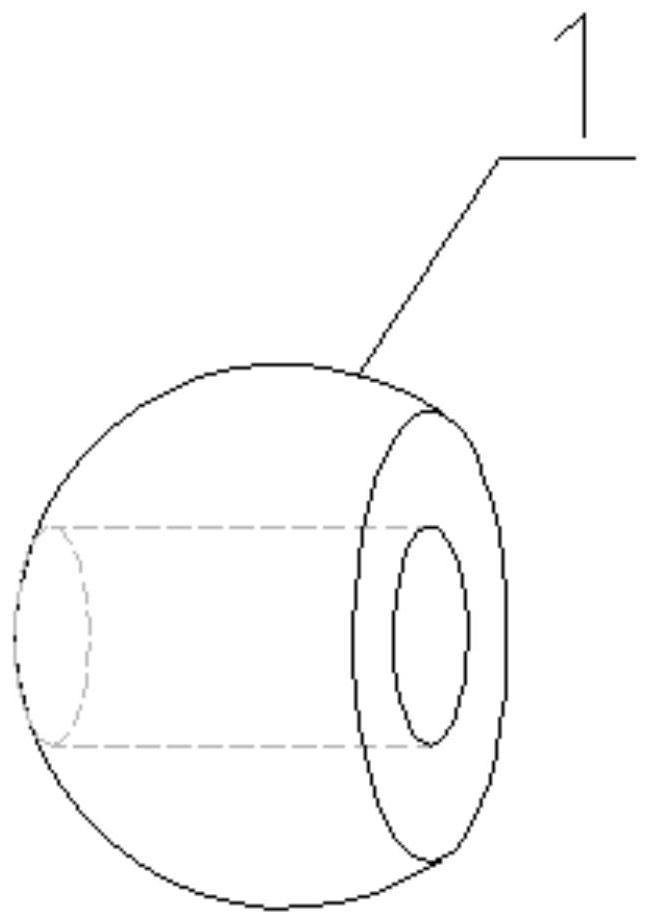

[0027] Step 13, after the anchor hole grouting reaches the design strength, the hemispherical bearing body 1 is loaded into the hemispherical anchor cup 2 on the precast concrete structure 5, and then the precast concrete structure ...

Embodiment 2

[0032] Project brief: There is an upright rock slope project whose stability does not meet the requirements of the specification, and slope support is required. After analysis, the pile + anchor cable support scheme is adopted to form the retaining wall anchoring structure.

[0033] Implementation steps

[0034] Step 21, firstly construct anti-sliding piles according to the design, namely concrete structure 5;

[0035] Step 22, after the concrete structure 5 meets the strength requirements, excavate the soil in front of the pile to the position of the first row of anchor cables 3 according to the design reverse method, implement the anchor cables 3, and carry out grouting of the anchor holes;

[0036] Step 23, chisel the protective layer of the steel reinforcement of the concrete structure 5 at the exit of the anchor hole on the concrete structure 5, put the spherical bearing body 1 into the hemispherical anchor cup 2, adjust the angle of the spherical bearing body 1 accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com