Application of polymethyl methacrylate

A technology of polymethyl methacrylate and transparency, applied in the field of materials science, can solve the problems of transparency and optical imaging defects, achieve complete and convenient imaging, and achieve remarkable technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

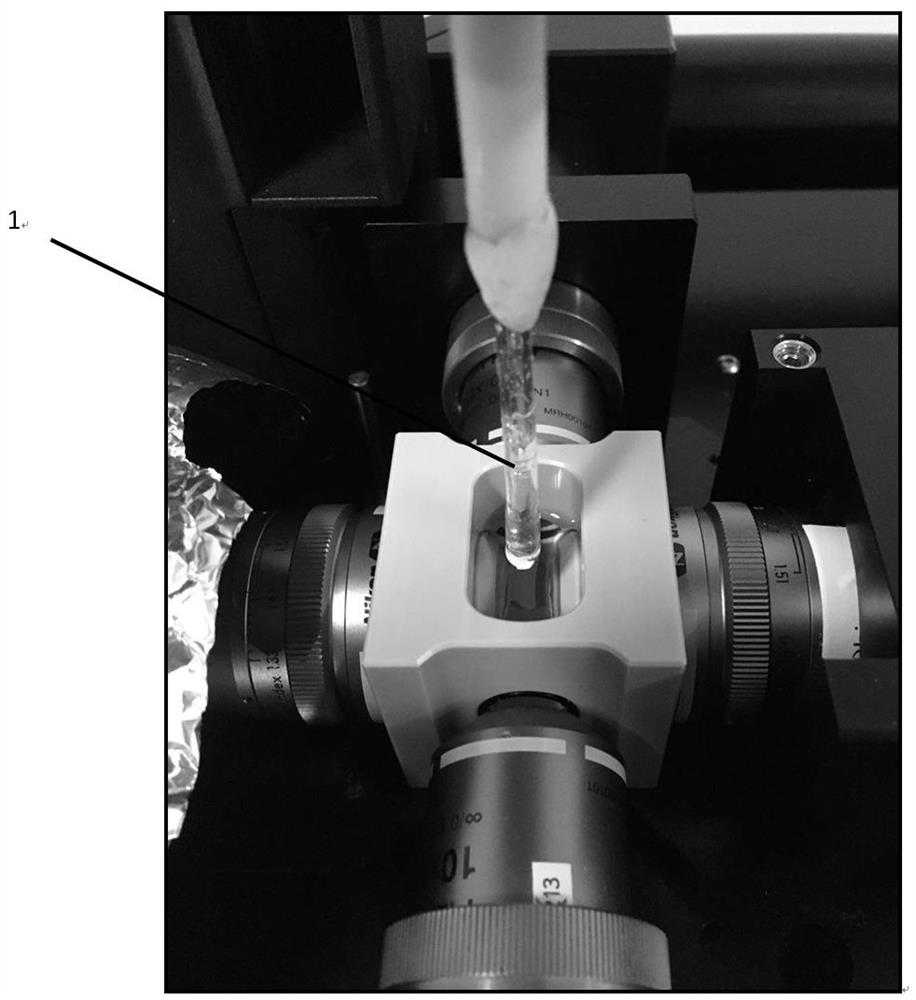

[0019] The present invention provides an application of polymethyl methacrylate material in the production of CUBIC transparent tissue microscopic imaging holder.

[0020] The present invention further provides a method for preparing a CUBIC transparent tissue microscopic imaging holder, using a polymethyl methacrylate material, the polymethyl methacrylate material is added to the blow molding device, injection device or, extrusion device molding.

[0021] Specifically, the heating temperature in the blow molding device, injection device or extrusion device is 80 ~ 300 ° C, preferably a temperature of 150 ~ 300 ° C.

[0022] Specifically, blow molding devices, injection devices or extrusion devices are prior art, which will not be repeated herein.

[0023] Specifically, the shape of the made holding vessel is tubular or sheet-shaped.

[0024] Specifically, the maximum diameter of the size of the holder made is 0.5-100 mm.

[0025]Specifically, the thickness of the made holding is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com