Novel inorganic environment-friendly flame retardant for flame-retardant paper

A flame retardant and flame retardant paper technology, applied in the field of inorganic flame retardants, can solve problems such as environmental and human hazards, and achieve the effects of high production value, high flame retardant efficiency, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

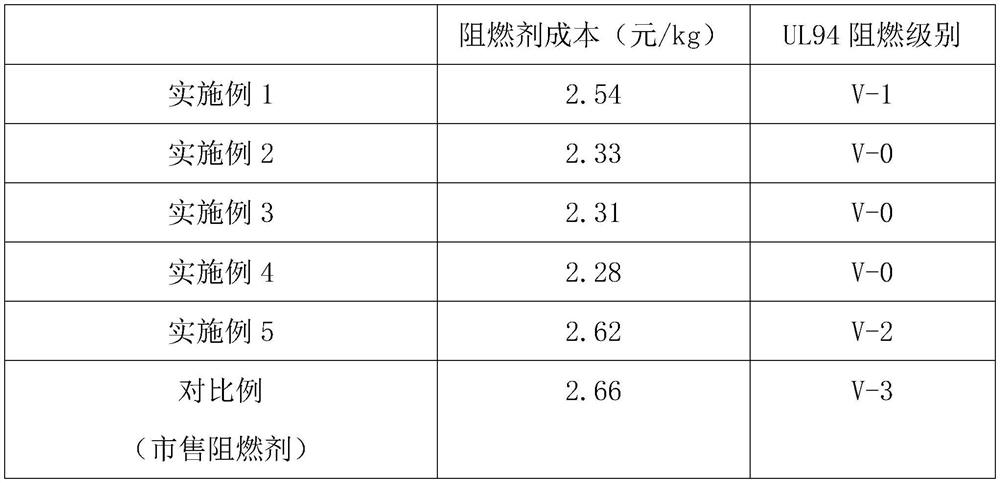

Examples

Embodiment 1

[0019] The invention provides a new type of inorganic environment-friendly flame retardant for flame retardant paper, which comprises the following raw materials in parts by weight: 19-25 parts of ammonium polyphosphate, 0.8-1.5 parts of magnesium hydroxide, 0.6-0.9 parts of magnesium oxide, 3.75-5.75 parts of B-type flame retardant, 0.8-1.3 parts of guanidine phosphate, the B-type flame retardant is set to be any one of polypropylene flame retardant, inorganic flame retardant and brominated flame retardant;

[0020] In this embodiment, the following raw materials are included in parts by weight: 25 parts of ammonium polyphosphate, 0.8 parts of magnesium hydroxide, 0.6 parts of magnesium oxide, 3.75 parts of B-type flame retardant, and 0.8 parts of guanidine phosphate. Type flame retardant is set to brominated flame retardant;

[0021] The specific processing steps are as follows: prepare ammonium polyphosphate, magnesium hydroxide, magnesium oxide, B-type flame retardant and ...

Embodiment 2

[0023] The invention provides a new type of inorganic environment-friendly flame retardant for flame retardant paper, which comprises the following raw materials in parts by weight: 19-25 parts of ammonium polyphosphate, 0.8-1.5 parts of magnesium hydroxide, 0.6-0.9 parts of magnesium oxide, 3.75-5.75 parts of B-type flame retardant, 0.8-1.3 parts of guanidine phosphate, the B-type flame retardant is set to be any one of polypropylene flame retardant, inorganic flame retardant and brominated flame retardant;

[0024] In this example, the following raw materials are included by weight: 22 parts of ammonium polyphosphate, 1.25 parts of magnesium hydroxide, 0.75 parts of magnesium oxide, 4.75 parts of B-type flame retardant, and 1.15 parts of guanidine phosphate. Type flame retardant is set to brominated flame retardant;

[0025] The specific processing steps are as follows: prepare ammonium polyphosphate, magnesium hydroxide, magnesium oxide, B-type flame retardant and guanidine...

Embodiment 3

[0027] The invention provides a new type of inorganic environment-friendly flame retardant for flame retardant paper, which comprises the following raw materials in parts by weight: 19-25 parts of ammonium polyphosphate, 0.8-1.5 parts of magnesium hydroxide, 0.6-0.9 parts of magnesium oxide, 3.75-5.75 parts of B-type flame retardant, 0.8-1.3 parts of guanidine phosphate, the B-type flame retardant is set to be any one of polypropylene flame retardant, inorganic flame retardant and brominated flame retardant;

[0028] In this example, the following raw materials are included by weight: 22 parts of ammonium polyphosphate, 1.25 parts of magnesium hydroxide, 0.75 parts of magnesium oxide, 4.75 parts of B-type flame retardant, and 1.15 parts of guanidine phosphate. Type flame retardant is set to polypropylene flame retardant;

[0029] The specific processing steps are as follows: prepare ammonium polyphosphate, magnesium hydroxide, magnesium oxide, B-type flame retardant and guanid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com