Waste silk recycling and feeding device in textile industry

A feeding device and textile industry technology, applied in textiles and papermaking, recycling technology, textile/flexible product manufacturing, etc., to reduce costs, simplify operations, and achieve good cutting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

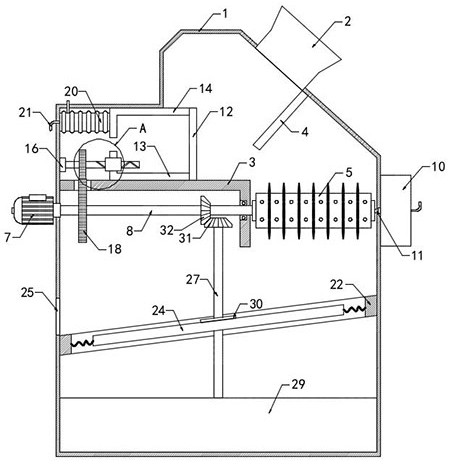

[0026] A collection tank 29 is fixed on the bottom of the recovery box 1 , and the collection tank 29 is located directly below the filter screen plate 24 .

[0027] The upper end of the annular coaming 26 is fixedly connected with a flexible baffle 30 , and the rotating rod 27 runs through the flexible baffle 30 , and the flexible baffle 30 can prevent the waste silk on the filter screen 24 from falling in the annular coaming 26 .

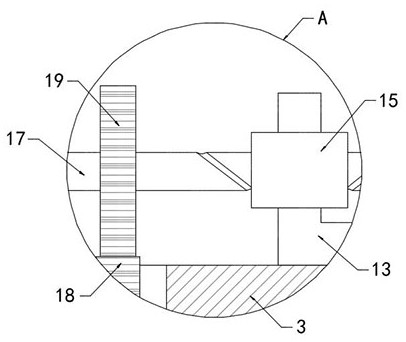

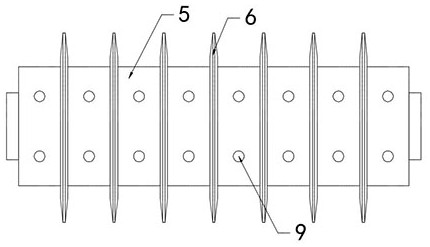

[0028]When the present invention is in use, the waste silk is dropped into the recovery box 1 from the feed hopper 2, and under the guidance of the material guide plate 4, the waste silk falls on the support plate 3, and the motor 7 drives the rotating shaft 8 to rotate when the motor 7 works, and the rotating shaft 8 drives The sector gear 18 fixed with it rotates, and when the sector gear 18 meshes with the driven gear 19, it can drive the driven gear 19 to rotate synchronously, and then the driven gear 19 drives the screw to rotate, and the tors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com