Production method of antibacterial quick-dry super cotton-like knitted fabric

A technology for knitted fabrics and production methods, applied in the processing of textile materials, equipment configuration for processing textile materials, spraying/jetting of textile materials, etc.

Inactive Publication Date: 2022-06-10

南通欧时力纺织品有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The present invention provides a method for producing antibacterial and quick-drying super-imitation cotton knitted fabrics, one of which is to have the ability to process the processed antibacterial cotton fabrics The characteristics of high-temperature sterilization and cleaning can solve the problem that after the antibacterial and quick-drying super imitation cotton knitted fabric is processed, there will be a lot of dust, textile fiber debris and bacterial adhesion on the surface during transportation; the other The purpose is to solve the problem of antibacterial and quick-drying super imitation cotton knitted fabrics. Generally, the internal water source is wrung out and placed in an open space to dry naturally. This method is time-consuming and will attach a lot of dust during the drying process. And the problem of bacteria, in order to achieve the effect of rapid high-temperature steam drying of the washed fabric

Method used

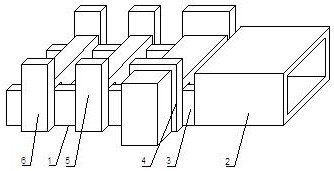

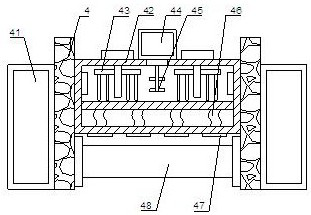

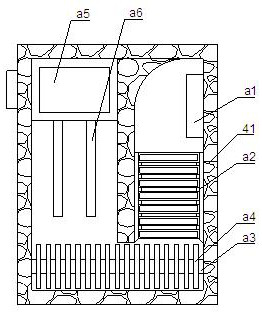

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a production method of an antibacterial quick-drying super cotton-like knitted fabric, and relates to the technical field of antibacterial quick-drying fabrics, and the production method comprises the following steps: step 1, preparing materials; 2, the materials are distributed according to the proportion; step 3, putting into a machine for processing; a1, cloth fibers are staggered, overlapped and knitted; a2, cleaning the cloth; a3, drying the cloth; a4, collecting the cloth; and step 5, filling cloth for sale. An entering water source is differentiated through the two-way differentiation plate, the water source is filtered in cooperation with the double filtering plate, the differentiated water source is atomized and sprayed out through the multi-pipe spraying head on the surface of the connecting plate, the water source has the advantages of being differentiated, filtered and atomized, and the problem that if the water source is not atomized, the water source cannot be atomized is solved. The problem that the cloth is blown away from the original position by a high-speed water source is solved, and the effects of differentiating, filtering, atomizing and spraying the water source are achieved.

Description

technical field [0001] The invention relates to the technical field of antibacterial and quick-drying fabrics, in particular to a production method of antibacterial and quick-drying super imitation cotton knitted fabrics. Background technique [0002] The fabric has good safety. It can efficiently and completely remove bacteria, fungus and mold on the fabric, keep the fabric clean, and prevent bacteria from regenerating and multiplying. There are following problems at prior art: 1. After the existing antibacterial and quick-drying super imitation cotton knitted fabrics are processed, there will be a lot of dust, textile fiber debris and bacterial adhesion problems during transportation on the surface; 2. After cleaning, the antibacterial and quick-drying super imitation cotton knitted fabrics are generally wrung out of the internal water source and placed in an open space to dry naturally. Problems of dust and bacteria. Contents of the invention [0003] The invention...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06B1/02D06B15/06D06B23/20D06B23/22F26B21/00A61L2/04A61L2/18

CPCD06B1/02D06B15/06D06B23/20D06B23/205D06B23/22A61L2/18A61L2/04F26B21/005A61L2202/26

Inventor 范金键

Owner 南通欧时力纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com