A method for obtaining static pressure matching accuracy in uniform region of large-scale supersonic jet flow field

A large-scale, static-pressure technology, used in the testing of machines/structural components, instruments, complex mathematical operations, etc., can solve the problems of restricting high-speed free jet wind tunnels, difficult to meet high-quality test requirements, etc., to expand the uniform area. , The idea is simple, and the effect of improving the uniformity of the flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

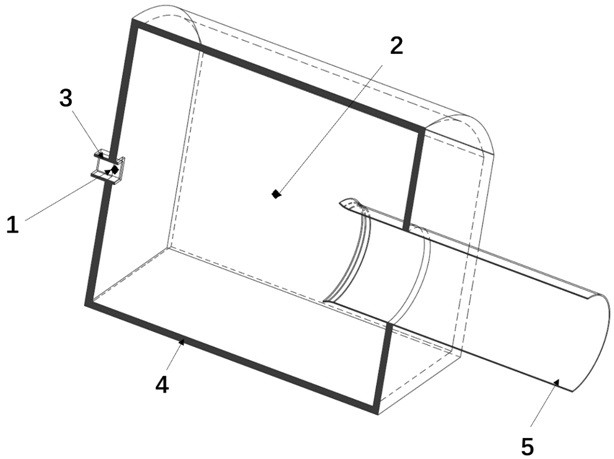

[0048] like figure 1 As shown, according to the airflow direction of the wind tunnel, the high-speed free jet wind tunnel includes a nozzle, a test chamber 4 and a collector 5 in sequence from front to back. The supersonic nozzle has a Mach number of 1.5.

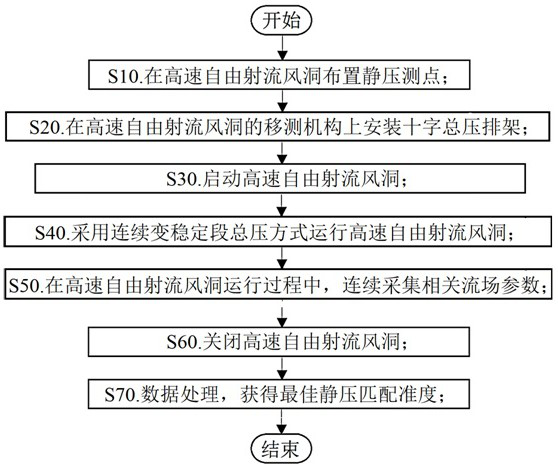

[0049] like figure 2 As shown, the specific implementation steps of this embodiment are as follows:

[0050] S10. Arrange static pressure measuring points in the high-speed free jet wind tunnel;

[0051] like figure 1 As shown in the figure, the nozzle outlet static pressure measuring point is arranged at the nozzle outlet of the high-speed free jet wind tunnel, and the static pressure at the nozzle outlet is measured. ; Arrange the reference point static pressure measuring point of the test cabin on the inner wall of the test cabin of the high-speed free jet wind tunnel, and measure the static pressure of the reference point of the test cabin ;

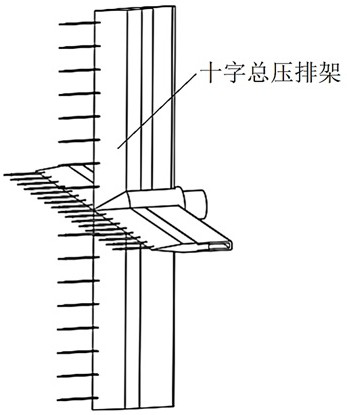

[0052] S20. Install the cross total pressure rack on the mobile meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com