A kind of auto parts grinding jig

A technology for auto parts and jigs, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of affecting the sealing performance of piston rings, easily producing inclination angles, and the inability to determine the radial direction of piston rings, etc., so as to simplify the equipment structure and operation process, improve The effect of clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the objects and advantages of the present invention more clear, the present invention will be specifically described below with reference to the embodiments. It should be understood that the following text is only used to describe one or more specific embodiments of the present invention, and does not strictly limit the protection scope of the specific claims of the present invention.

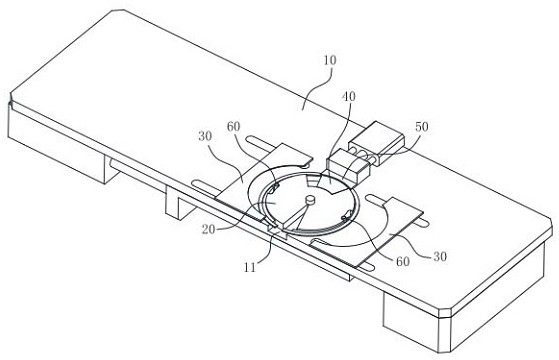

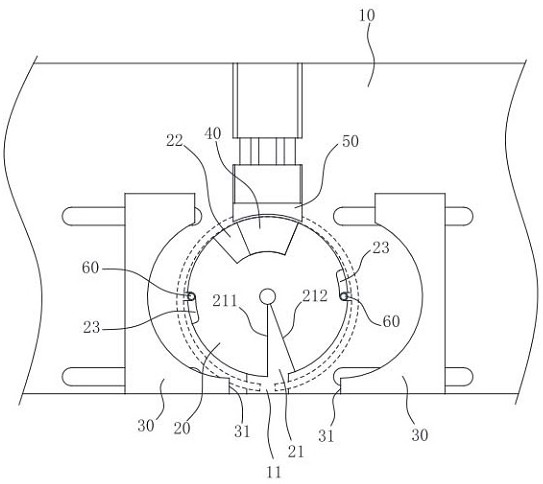

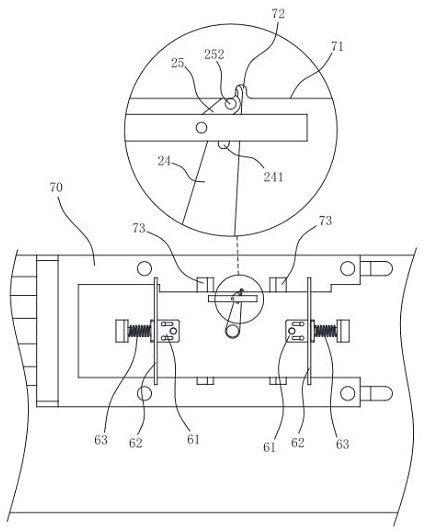

[0035] like figure 1 , 2 , shown in 4, a grinding fixture for automobile parts, used for the positioning of the end of the piston ring when grinding, including a flat support plate 10, used to fit the bottom surface of the piston ring; 1. The inner positioning part 20 has a first arc-shaped surface 201 for fitting the inner ring of the piston ring; The diameter of the first arc-shaped surface 201 is equal to the assembly inner diameter of the piston ring, that is, the inner diameter when the piston ring is elastically deformed after being loaded into the cylinder liner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com