Planetary type transverse support mechanism capable of adjusting common rotation speed ratio and rotation speed ratio and stirring machine adopting planetary type transverse support mechanism

A revolution and planetary technology, applied to mixer accessories, mixers with rotating containers, mixers, etc., can solve problems such as the inability to adjust the speed ratio at full speed, and achieve the effect of ensuring stability and expanding the adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

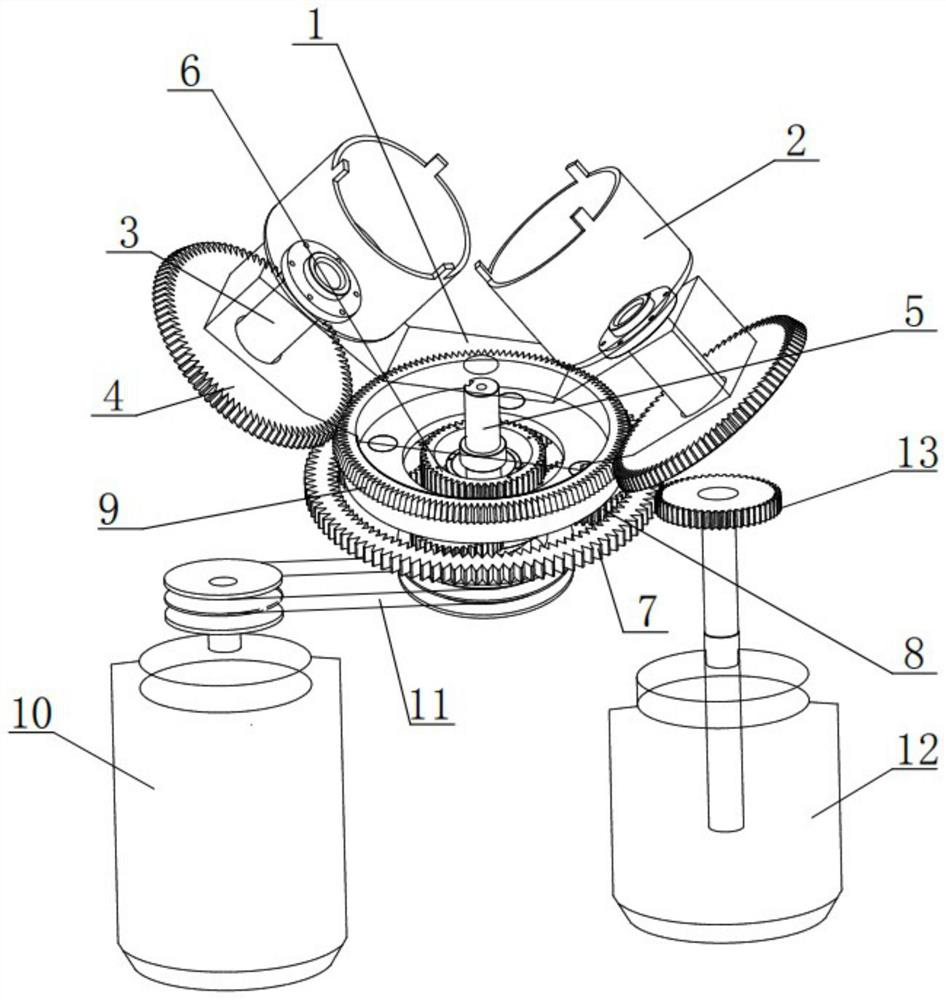

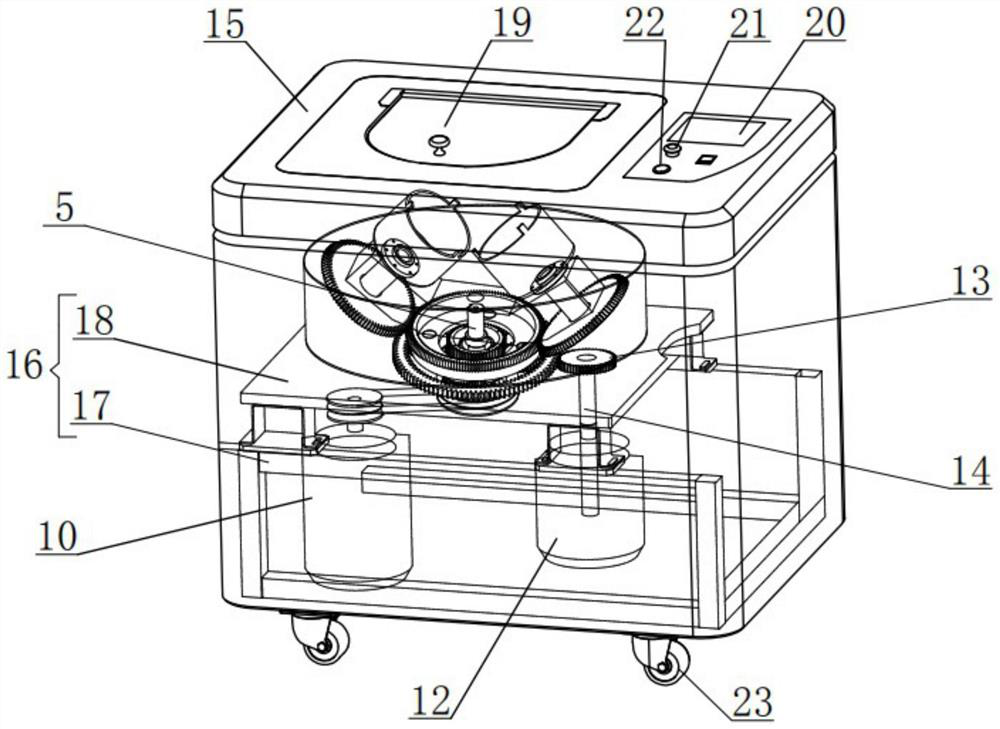

[0040] like figure 1 As shown in the figure, a planetary transverse support mechanism that can adjust the revolution ratio of the public to the self includes a transverse support 1, a rotor cup 2, a sun gear 6, a ring gear structure 7, a bevel-tooth integrated planetary carrier 9, a planetary gear 8, a revolution Motor 10 and autorotation motor 12 .

[0041] A revolving shaft 5 is fixedly inserted on the horizontal support 1 , and a central gear 6 is fixedly sleeved on the outside of the revolving shaft 5 . Both the central gear 6 and the lateral support 1 are fixedly connected with the revolving shaft 5 and rotate together with the revolving shaft 5 .

[0042] Wherein, the output shaft of the revolution motor 10 is drivingly connected to the revolution shaft 5 through a revolution drive assembly, and the revolution drive assembly is a coupling, a bevel gear assembly, a belt assembly or a spur gear assembly. In this embodiment, the revolution drive assembly is a belt assemb...

Embodiment 2

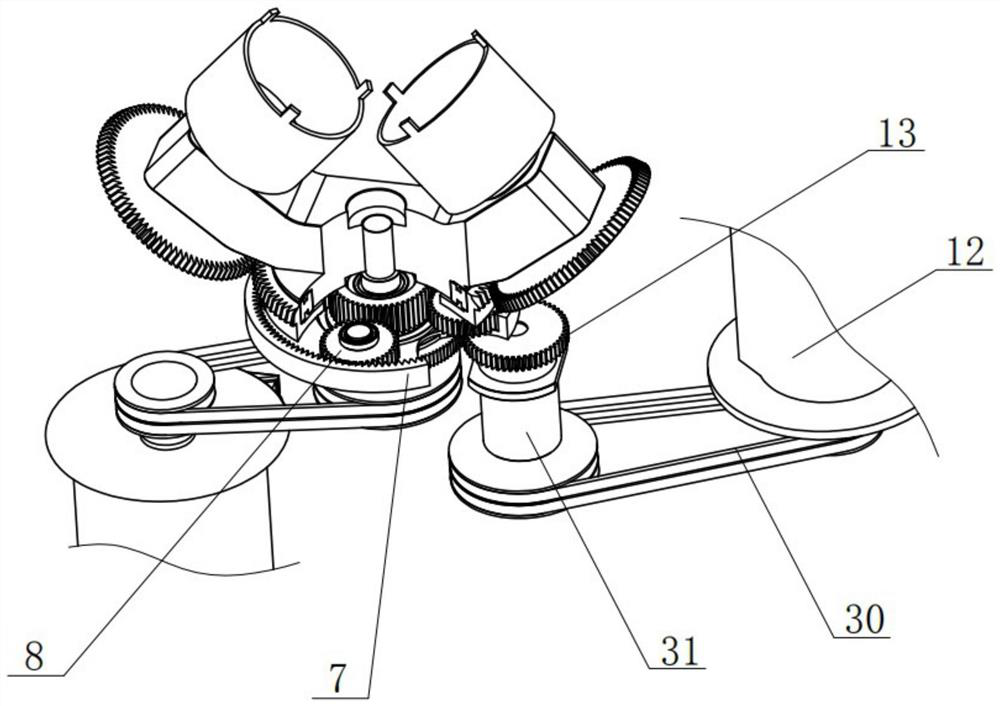

[0060] In this embodiment, the autorotation drive assembly of the planetary transverse support mechanism includes a transmission spur gear 13 , a transmission shaft 31 , two autorotation pulleys and an autorotation belt 30 . The two autorotation pulleys are respectively installed on one end of the transmission shaft 31 and the output shaft of the autorotation motor 12. The autorotation belt 30 is installed on the two autorotation pulleys. The loop structure 7 is engaged in a meshing connection.

[0061] The ring gear structure 7 includes an upper gear ring and a lower gear ring that are connected up and down. The upper gear ring and the lower gear ring are coaxial and integrally arranged. The inner side of the upper gear ring and the outer side of the lower gear ring are provided with tooth-shaped structures. The toothed structure on the inner side of the ring gear is meshed with the planetary gear 8 , and the toothed structure on the outer side of the lower ring gear is meshe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com