Radial thrust acquisition mechanism and thrust vector measurement device and method

A technology of radial thrust and thrust vector, applied in the field of rockets, can solve problems such as inability to realize radial measurement and inability to obtain direction information of engine combined thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

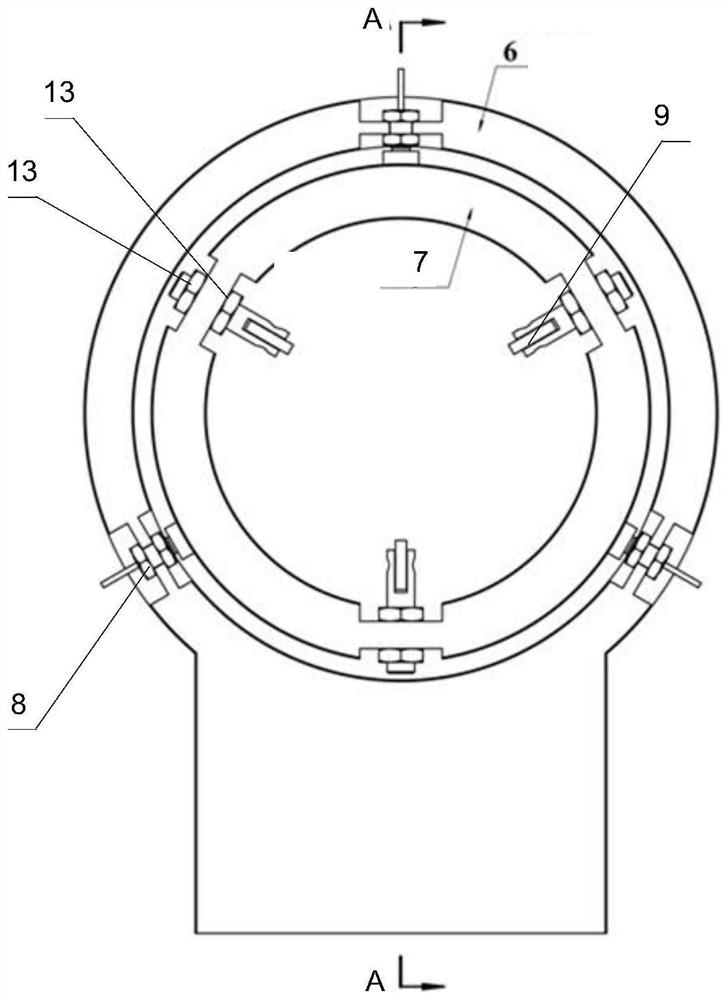

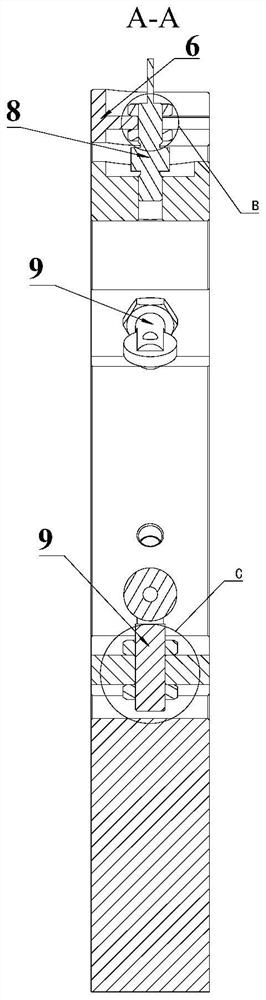

[0071] see Figure 1 to Figure 6 As shown, the embodiment of the present application provides a radial thrust acquisition mechanism for detecting the radial thrust of the component to be tested, especially the radial thrust of the rocket engine 12 .

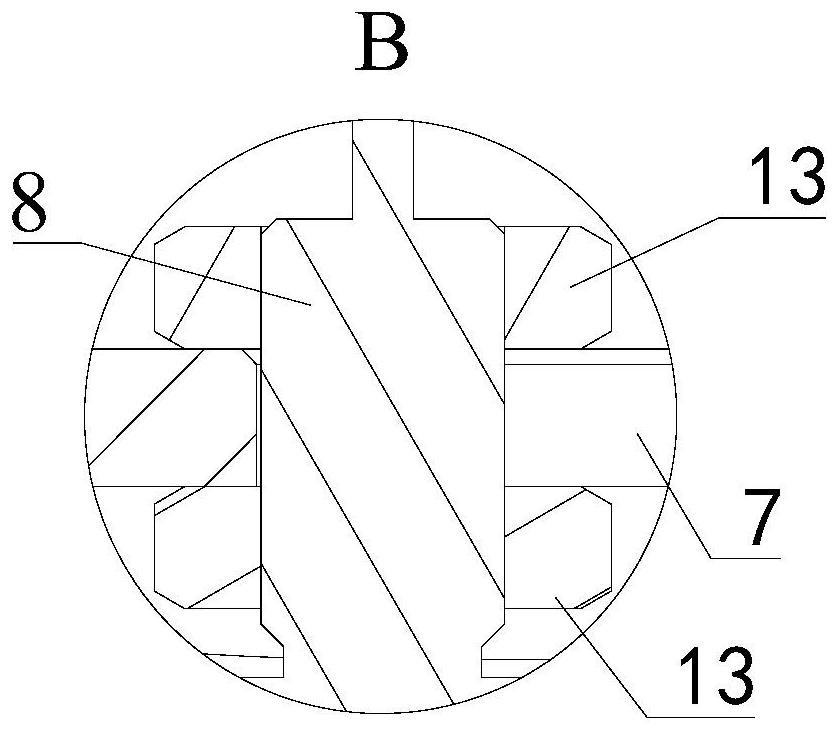

[0072] The radial thrust collection mechanism provided in this embodiment for the thrust vector measurement device includes a first fixed frame, a first moving frame, a pulley 9 and a radial tension pressure sensor 8 .

[0073] Hereinafter, the above-mentioned components of the radial thrust collecting mechanism will be described in detail.

[0074] see Figure 1 to Figure 6 , in the optional solution of this embodiment, the first fixed frame is provided with an installation hole, the first movable frame is arranged in the installation hole, the first movable frame is annular, and the inner space of the first movable frame forms a predetermined cylindrical area, and the predetermined cylindrical area is formed. The cylindrical ...

Embodiment 2

[0088] The second embodiment provides a thrust vector measurement device, which includes the radial thrust collecting mechanism in the first embodiment, and the technical features of the radial thrust collecting mechanism disclosed in the first embodiment are also applicable to this embodiment. The technical features of a disclosed radial thrust collecting mechanism will not be described again.

[0089] combine Figure 1 to Figure 6 and see Figure 7 to Figure 10 As shown, the thrust vector measurement device provided in this embodiment is used for vector measurement of the thrust of the rocket engine 12 .

[0090] The rocket motor 12 includes a head, a body, and a tail arranged in sequence along its own axis. The rocket engine thrust vector measurement device includes a working platform 1, an axial thrust acquisition mechanism and at least one radial thrust acquisition mechanism.

[0091] Hereinafter, the above-mentioned components of the rocket engine 12 will be described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com