A kind of production equipment and process of supercapacitor composite electrode material

A composite electrode and supercapacitor technology, used in capacitors, capacitor manufacturing, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of general stirring effect, uncontrollable temperature, uneven heating, etc., and achieve good stirring effect and uniform heating. , easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

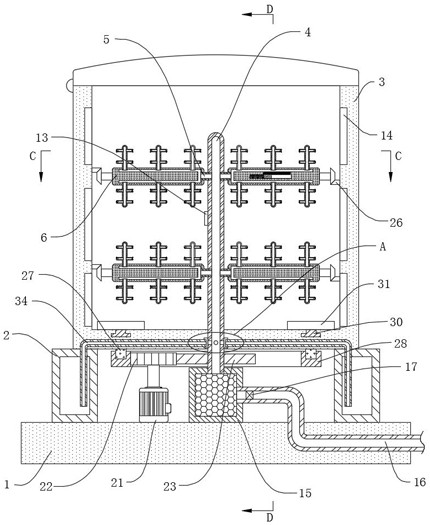

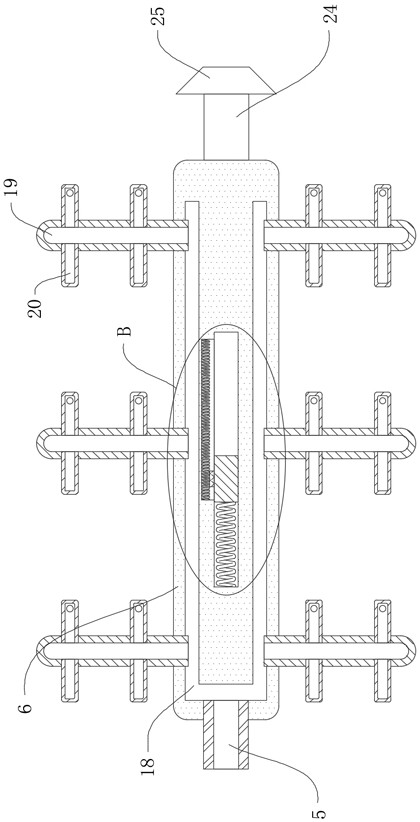

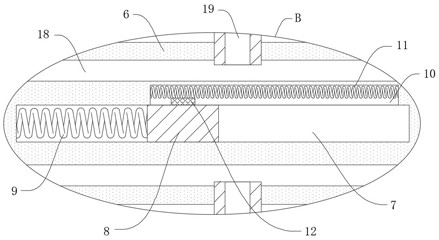

[0035] refer to Figure 1-8 , a production equipment for supercapacitor composite electrode materials, comprising a base 1, a support block 2 is fixedly connected to the upper surface of the base 1, a main body 3 is fixedly connected to the upper surface of the support block 2, and an adjustment mechanism is arranged in the main body 3;

[0036]The adjustment mechanism includes a first rotating tube 4 that is connected to the bottom wall of the main body 3 through a bearing and is rotatably connected. A section of the first rotating tube 4 located in the main body 3 is connected to a number of connecting tubes 5 through the bearing, and the connecting tube 5 is fixedly connected to a rotating tube. Block 6, one of the rotating blocks 6 is provided with a functional cavity 7, a centrifugal column 8 is slidably connected in the functional cavity 7, and a conductive spring 9 is fixedly connected between the centrifugal column 8 and the inner wall of the functional cavity 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com