Water resistance industrial boiler

An industrial boiler, water resistance technology, applied in electrode boilers, steam boilers, liquid resistors, etc., can solve the problems of high opening cost, easy generation of hydrogen, leakage, etc., to ensure the safety of boiler operation, avoid electrode dry burning, improve The effect of heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

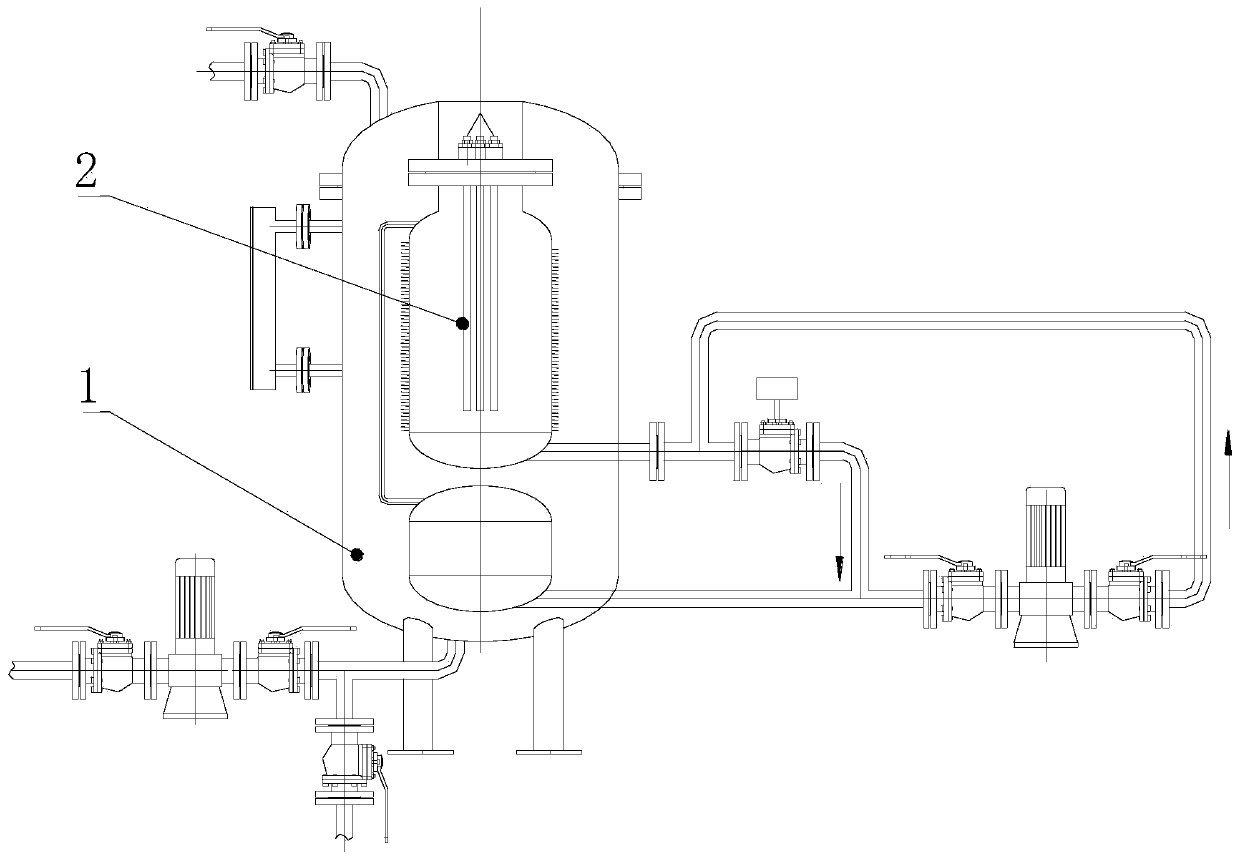

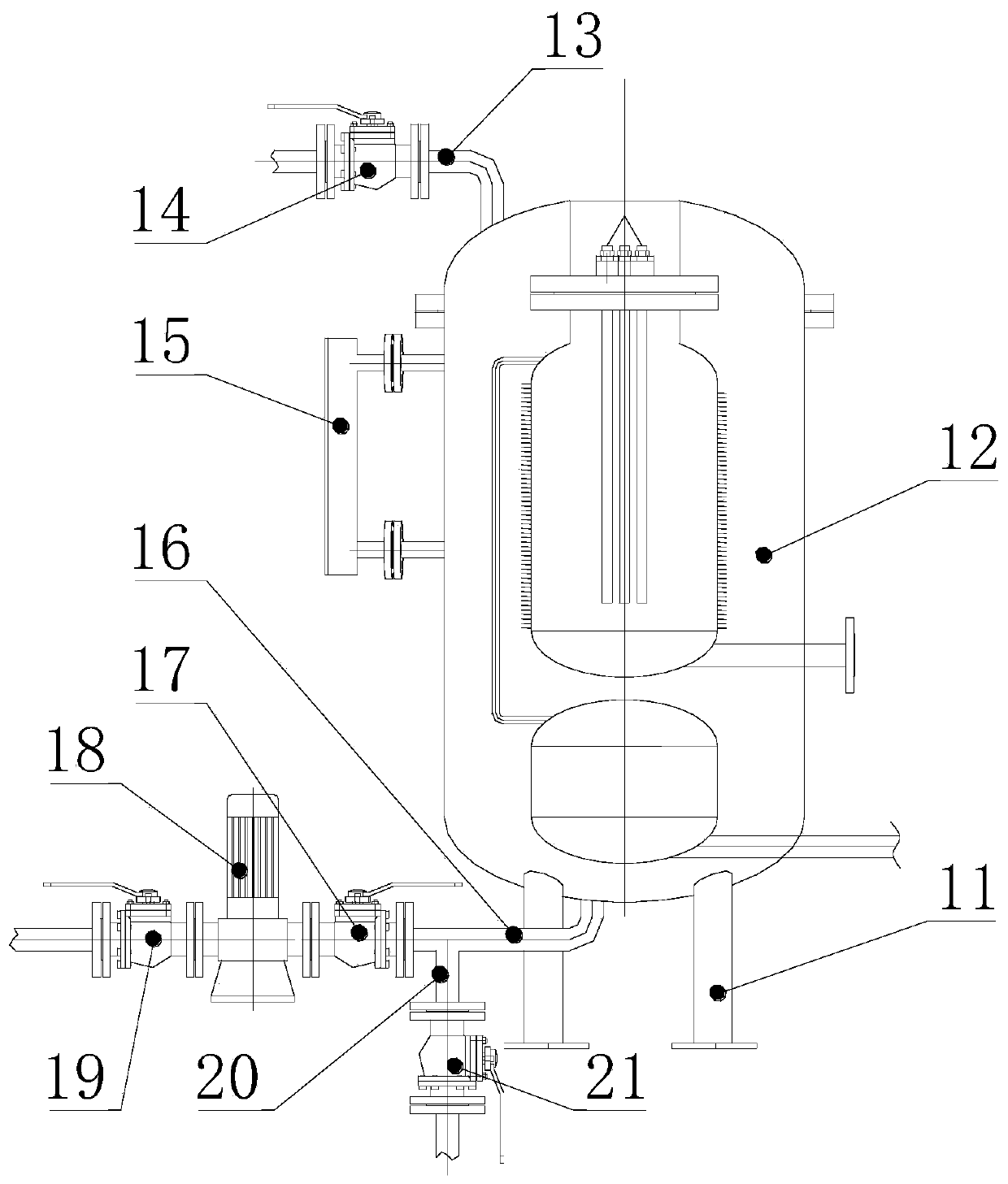

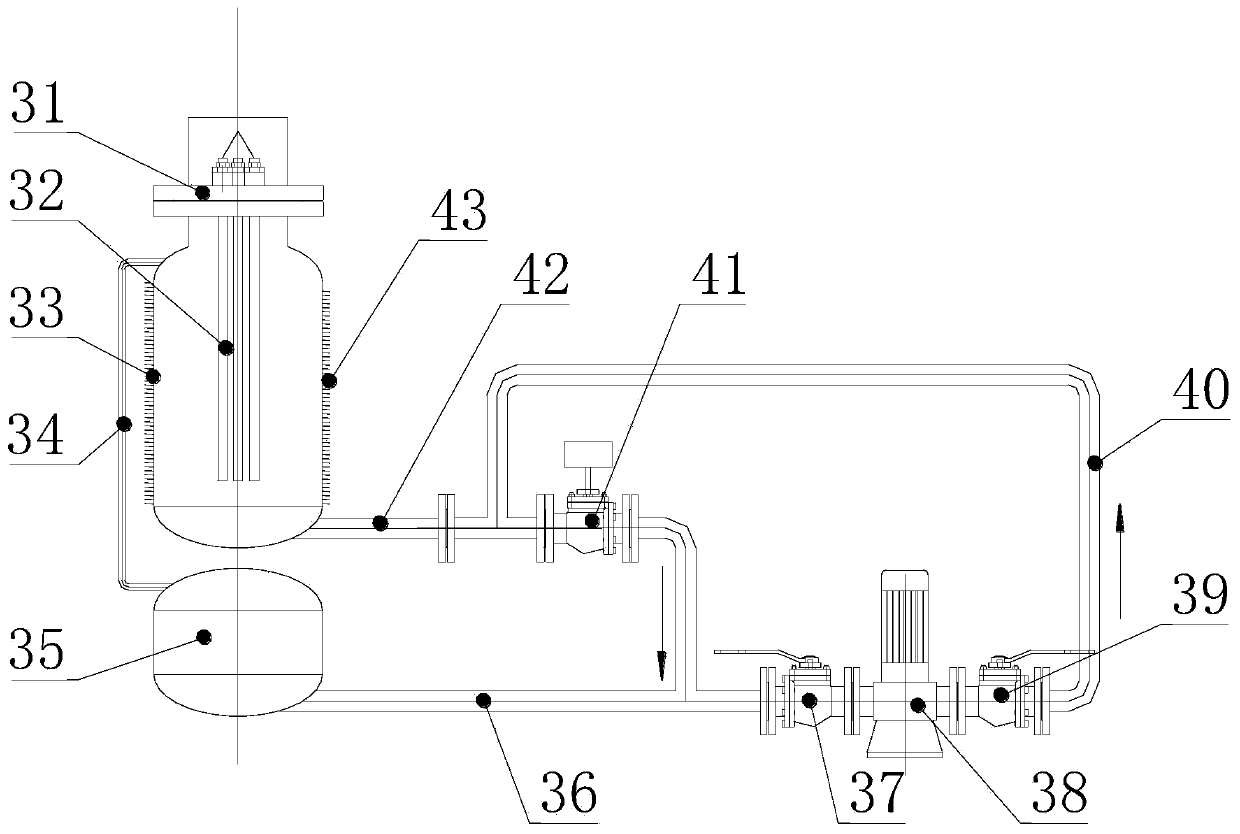

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0033] like Figure 1-2 As shown, the water resistance industrial boiler includes a boiler body 1 and a water resistance heat generator 2. The boiler body 1 is composed of a boiler shell 12, a working fluid input pipe and a working fluid output pipe. The boiler shell 12 is fixed on On the support column 11, the bottom of the boiler shell 12 is provided with a working fluid input port 16, and the top of the boiler shell 12 is provided with a working fluid output port, and the working fluid input port 16 is connected to a working fluid input pipe, The working outlet 13 is connected to the working fluid output pipe, and the boiler shell 12 is provided with a water resistance heat energy generator 2 . The water resistance thermal generator 2 is used to heat the working fluid, and the water resistance thermal generator 2 directly conducts convective heat exchange with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com