Engine hanger for tilting ducted aircraft

An engine pylon and engine technology, which is applied to the power plant, aircraft parts, wings and other directions of the aircraft, can solve problems such as low efficiency, and achieve the effects of improving safety, improving flutter characteristics, and improving aircraft range and payload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

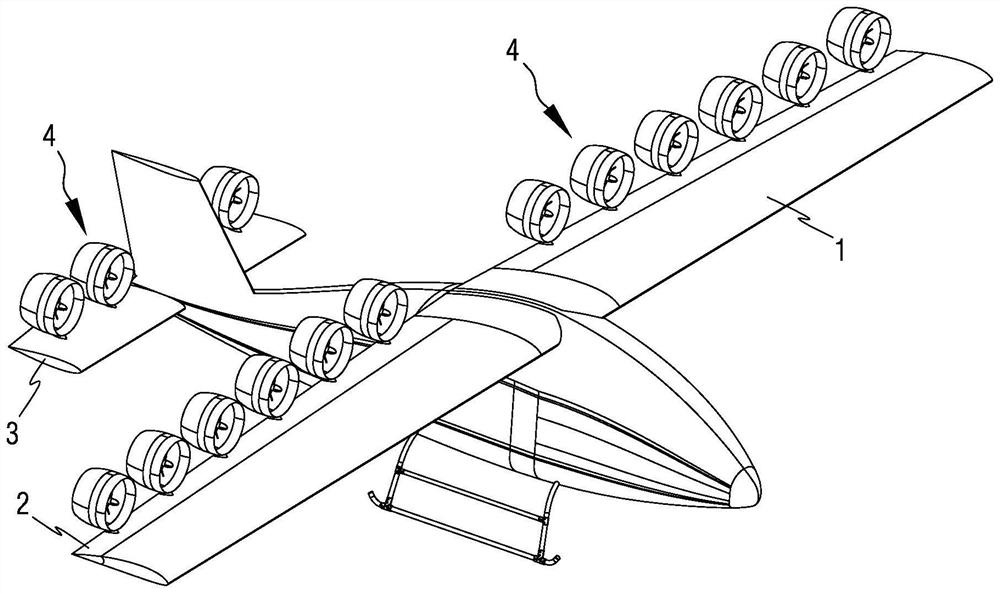

[0021] In the present invention, the electric propulsion engine 4 is installed on the integral flaperon and the full-motion horizontal tail, and the integral flaperon and the full-motion horizontal tail itself can deflect the direction, and the conventional design itself has a driving integral flap The structure of aileron and full-moving horizontal tail deflection, these are inherent functional structures of the aircraft, and are not dead weight structures. The invention utilizes the conventional structure of the aircraft to drive the electric propulsion engine to switch between the level flight state and the vertical take-off and landing state, does not need to set up an additional deflection mechanism, has no dead weight at all, reduces the energy consumption of the aircraft, and is beneficial to improve the aircraft range and Payload.

[0022] It should be noted that before the current electric propulsion technology matures, the structure of the movable surface such as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com