Composite material winding regeneration cooling thrust chamber and processing technology

A composite material and regenerative cooling technology, which is applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve the problems of increased thrust chamber wall thickness, increased cooling channel height, and reduced cooling effect of regenerative cooling channels, achieving improved Cooling effect, small wall thickness, low height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

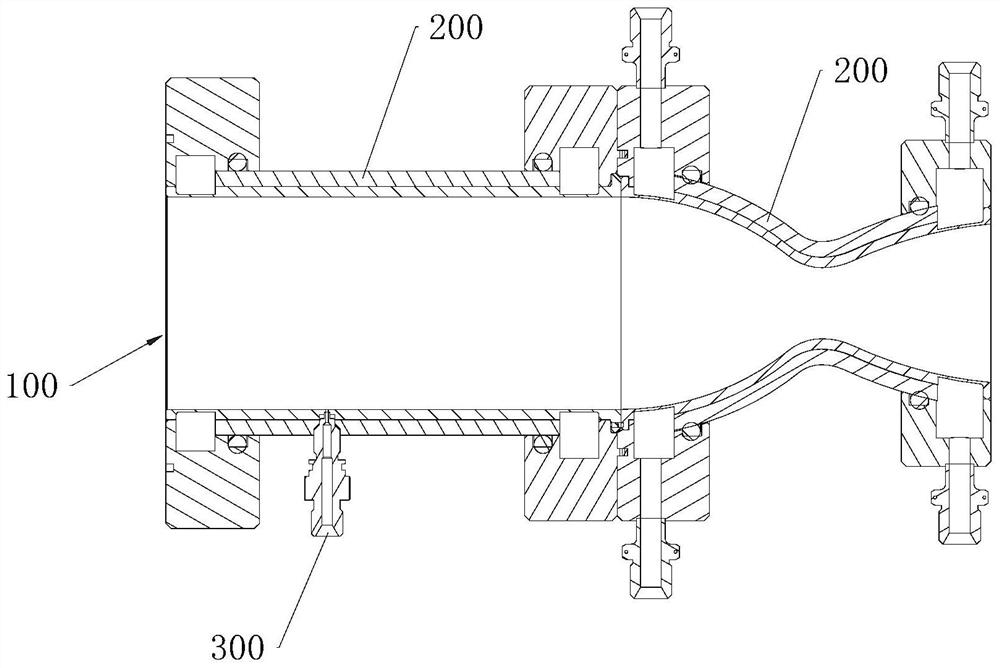

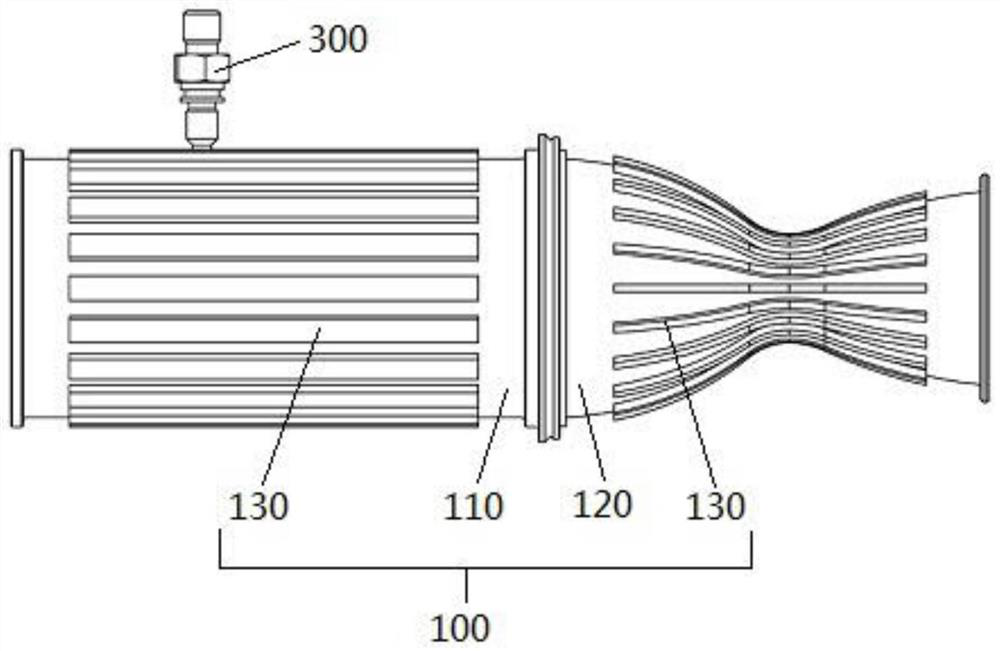

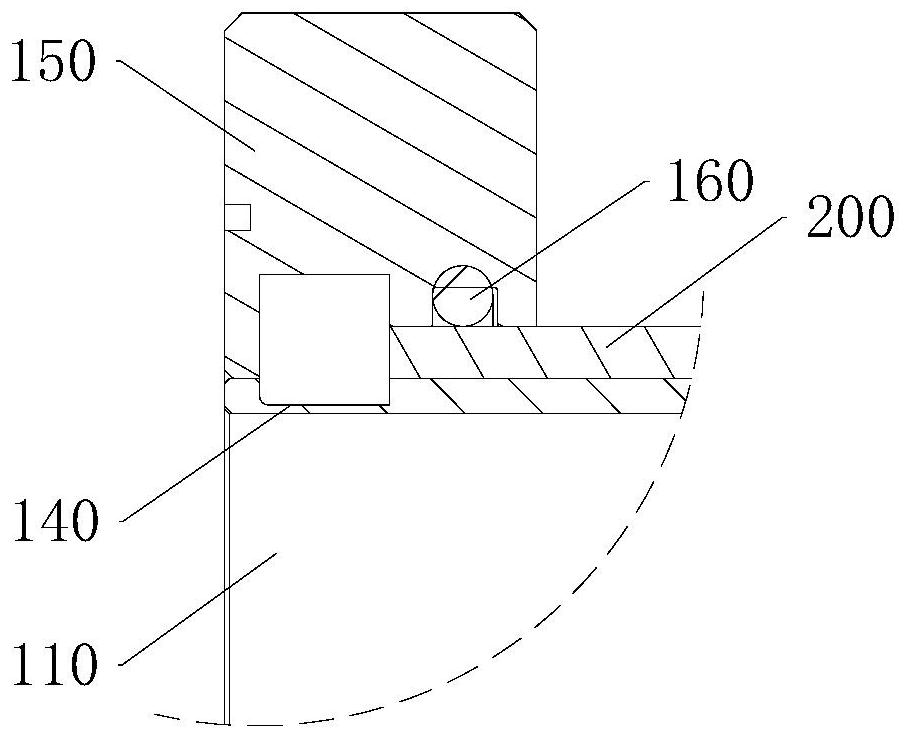

[0059] see figure 1 , This embodiment provides a composite material winding regeneration cooling thrust chamber (hereinafter referred to as "thrust chamber"), which is applied to a liquid rocket engine, which includes a thrust chamber body 100 and a composite material layer 200 .

[0060] The composite material layer 200 is sleeved on the side wall of the thrust chamber body 100 to form a sandwich structure, and a cooling channel exists between the composite material layer 200 and the thrust chamber body 100 . The purpose of cooling the thrust chamber body 100 can be achieved by using the propellant as a coolant, making it flow through the cooling channel, and removing the heat on the side wall of the thrust chamber body 100 through the convection heat exchange heat. After the propellant flows out of the cooling channel, it is injected into the combustion chamber inside the thrust chamber body 100 through the injection panel, and the heat absorbed by the propellant is then ret...

Embodiment 2

[0081] see Figure 4 , this embodiment provides a machining process for machining a cooling channel on the thrust chamber body 100, which includes the following steps:

[0082] S1, machining a cooling groove on the outer side wall of the thrust chamber body 100, the specific steps are as follows:

[0083] S1-1, design the thrust chamber body 100 profile and cooling groove.

[0084] S1-2, a cooling groove is milled on the outer side wall of the thrust chamber body 100, and a rib plate 130 is formed at the same time.

[0085] S2, install the measuring nozzle 300.

[0086] Specifically, all the measuring nozzles 300 arranged in the combustion chamber section 110 are connected to the combustion chamber section 110 by welding or sealing threads, and it is confirmed that there is no leakage between the combustion chamber and the cooling groove, so as to ensure the safety of the thrust chamber. sex.

[0087] S3, winding composite fibers on the thrust chamber body 100 to form a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com