Gas injector for injecting gas fuel

A gas injector and gaseous fuel technology, applied in fuel injection devices, special fuel injection devices, fuel injection devices with special measures affecting magnetic flux, etc., can solve problems such as fracture sealing, gas leakage, gas cracks, etc., to achieve High mechanical stability, good welding characteristics, effect of small saturation induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

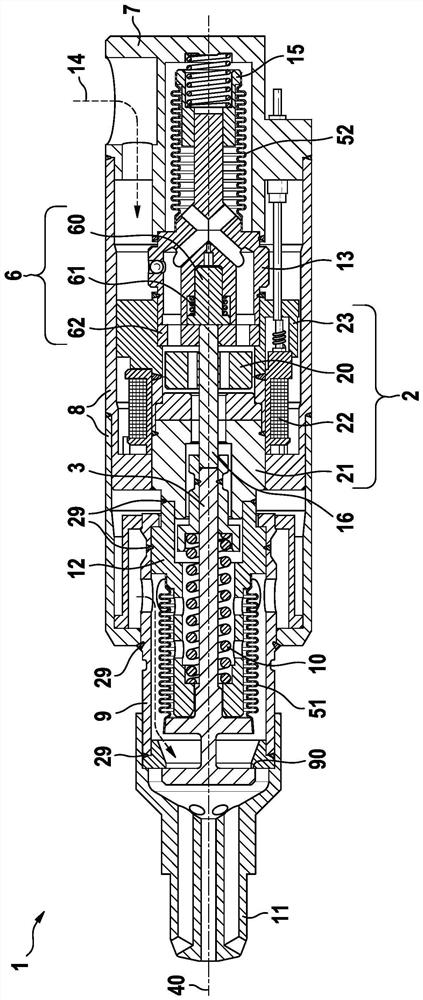

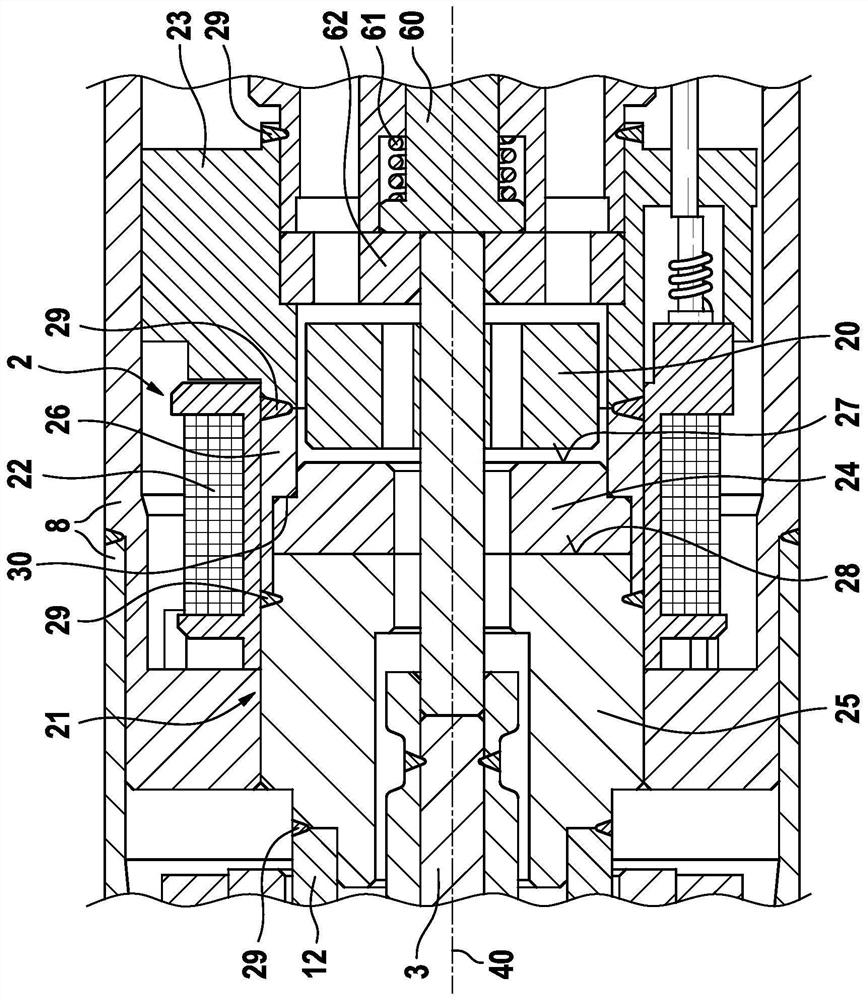

[0021] Refer below Figures 1 to 4 The gas injector 1 according to a preferred embodiment of the present invention is described in detail. like figure 1 and figure 2 As shown in the detailed view in , a gas injector 1 for blowing in gaseous fuel comprises a magnetic actuator 2 which moves a closing element 3 . The closing element 3 extends along the longitudinal axis 40 of the gas injector 1 . In the embodiment shown, the closing element 3 opens outwards. exist figure 1 A closed state is shown for this.

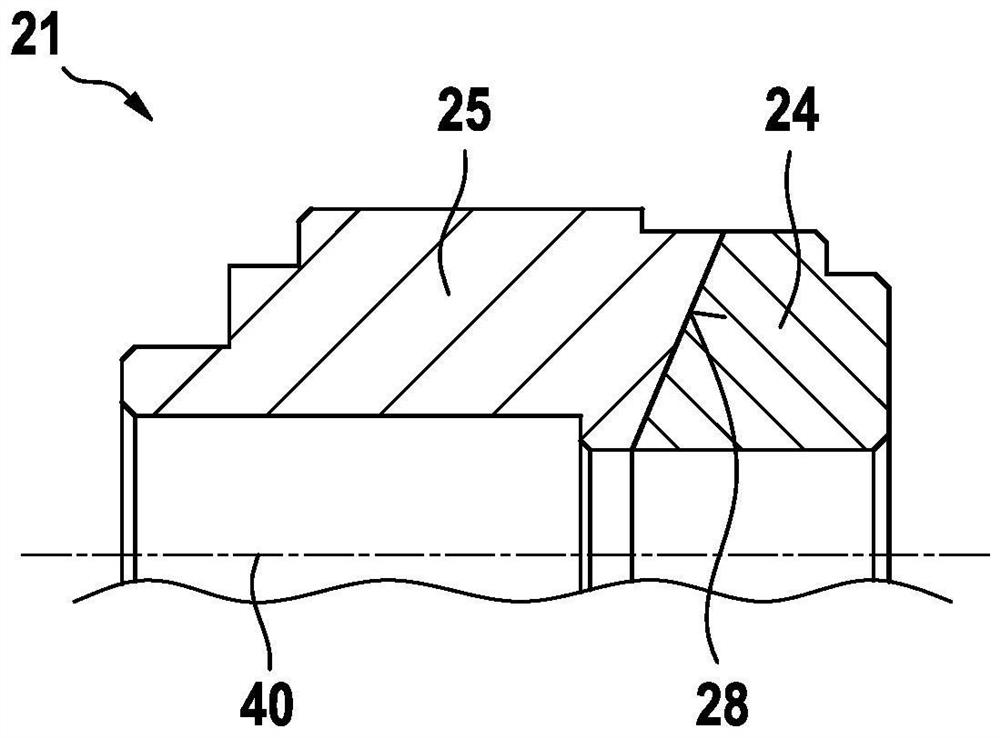

[0022] The magnetic actuator 2 includes an armature 20 which rests on the closing element 3 by means of an armature pin 24 . Furthermore, the magnetic actuator 2 includes an inner pole 21 , a coil 22 and a magnetic housing 23 which ensures the magnetic return of the magnetic actuator 2 .

[0023] Furthermore, the gas injector comprises a body 7 having a lateral port through which the gaseous fuel is supplied. The valve housing 8 is fixed to the main body 7 . The mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com