Two-dimensional motor piston pump

A piston pump and pump body technology, applied in the field of two-dimensional motor piston pumps, can solve problems such as motor heating and mechanical wear, and achieve the effects of improving efficiency, reducing friction, and high volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

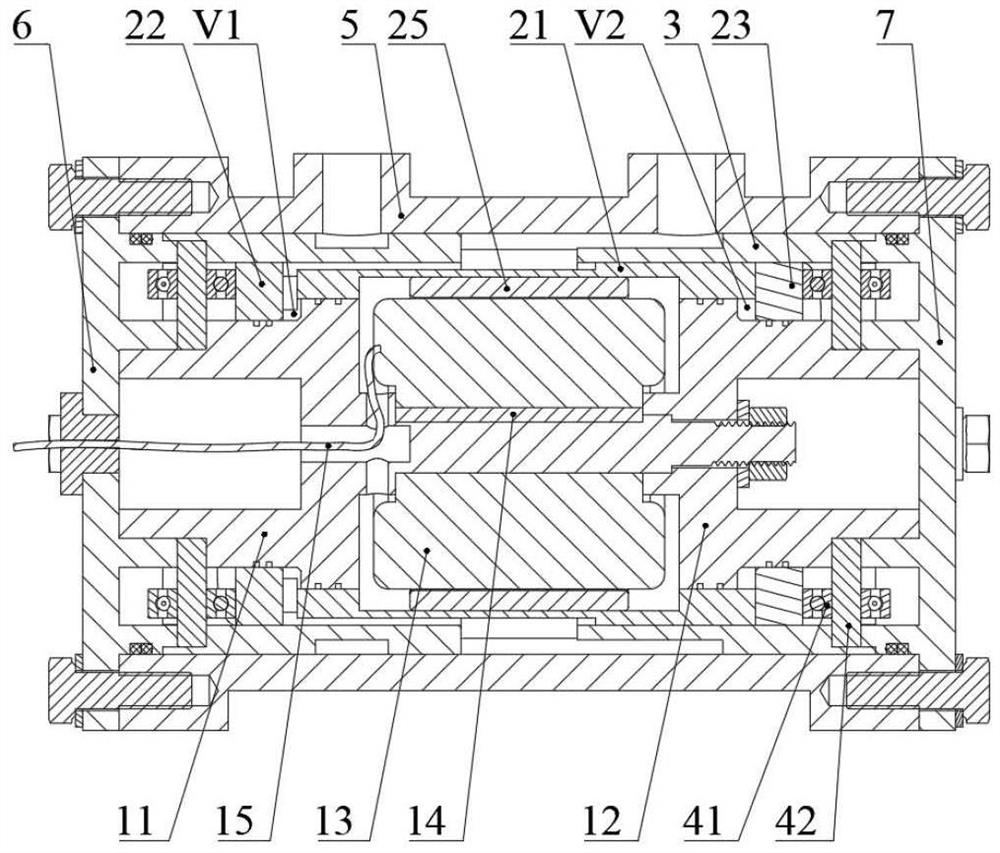

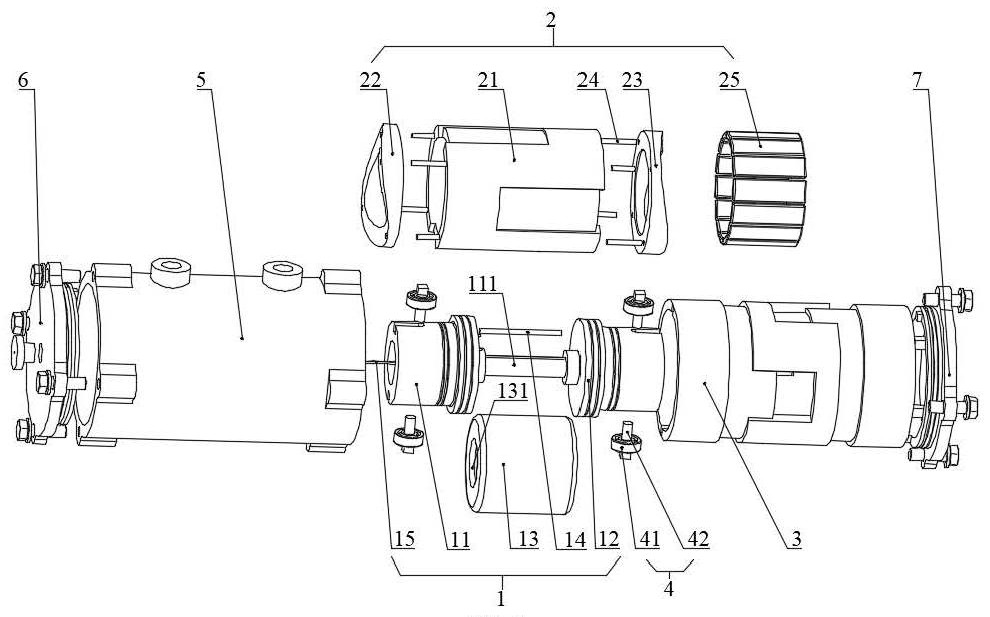

[0030] In this embodiment, the stator coil 13 of the motor is filled with working fluid, such as hydraulic oil. During operation, the heat generated by easily heating elements such as winding wires and silicon steel sheets can be dissipated through oil cooling, so when working in an inflammable and explosive environment More security.

[0031] In this embodiment, the stator 1 of the motor further includes wires and a controller 15 connected to the stator coil 13 and drawn out from a hole on the shaft of the left stator 11 for controlling the operation of the motor.

[0032] In this embodiment, the outer rotor 2 of the motor further includes a distribution rotor 21 coaxially sleeved on the outside of the stator 1. The inner surface of the distribution rotor 21 has an annular wide groove and pin holes are formed on both ends.

[0033] In the example of this embodiment, the outer rotor 2 of the motor further includes permanent magnets 25, and a plurality of permanent magnets 25 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com