Metering module structure of integrated ultrasonic water meter and assembling method of metering module structure

A modular structure, ultrasonic technology, applied in the direction of measuring devices, volume measurement, liquid/fluid solid measurement, etc., can solve the problems of poor flow field stability, large space occupation, inconvenient installation, etc., to improve flow field stability , space-saving and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to illustrate the present invention, but not to limit the present invention.

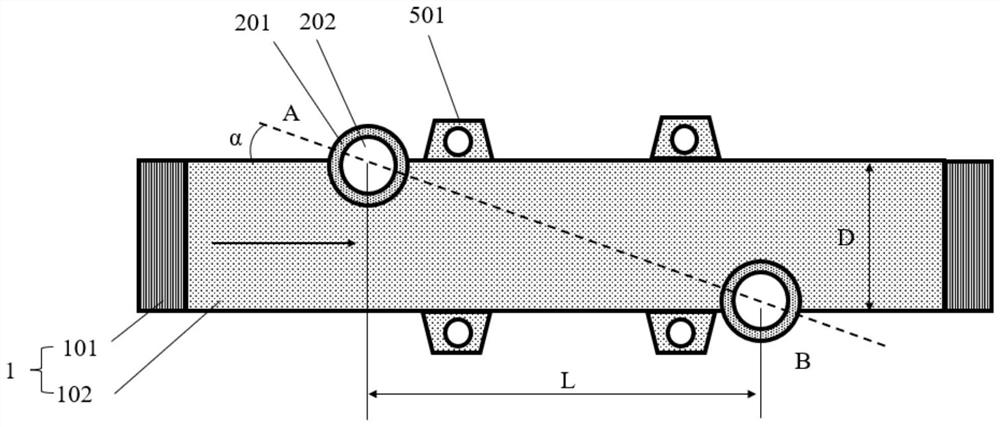

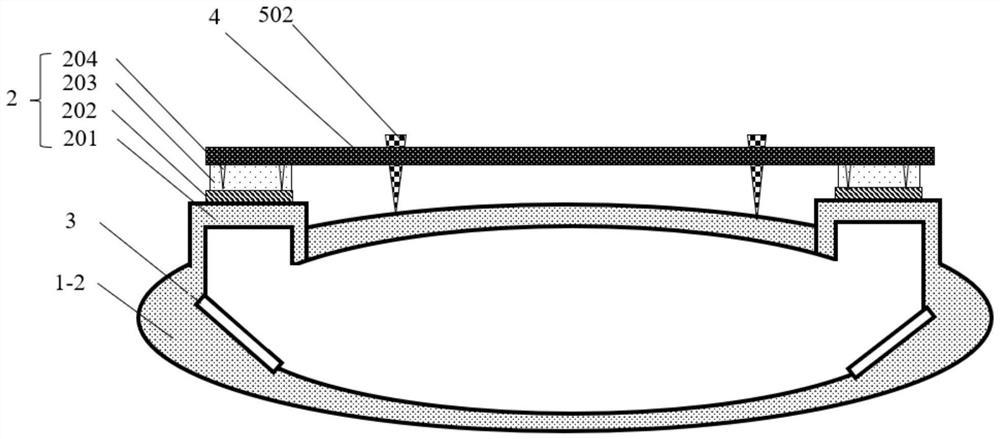

[0042] like figure 1 , 2 As shown, a metering module structure of an integrated ultrasonic water meter includes a water meter pipe section 1, a pair of ultrasonic transducers 2, a pair of reflecting mirrors 3 and a water meter metering PCB 4.

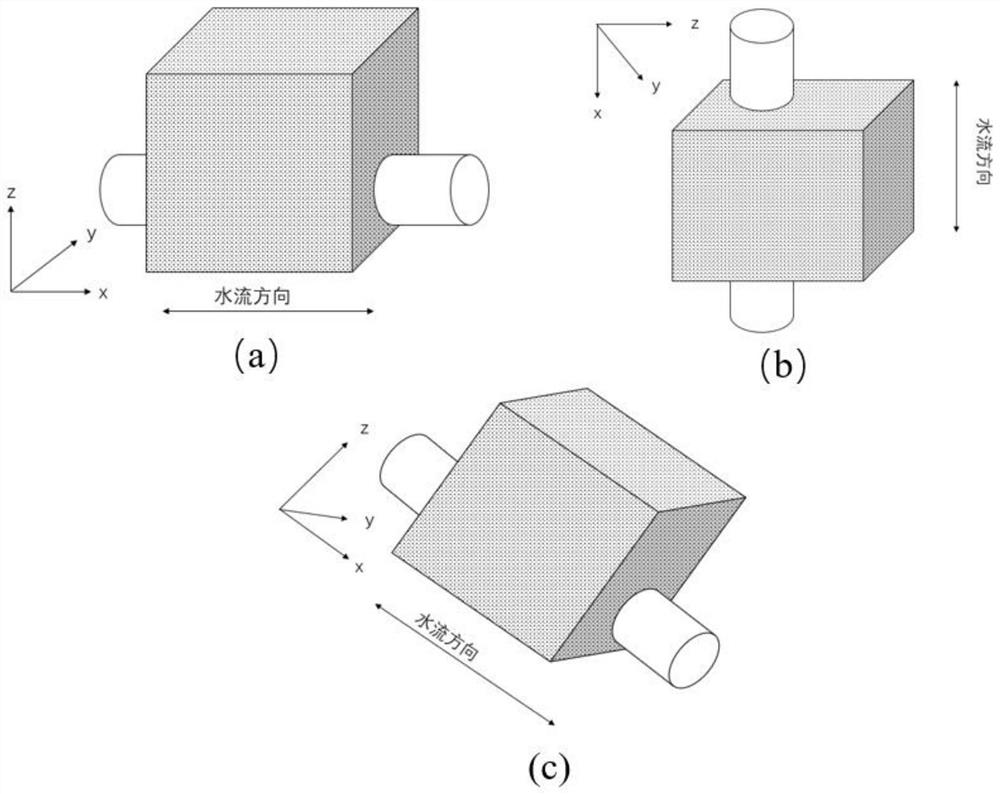

[0043] The pipe section 1 of the water meter is the part where the water flows through the ultrasonic water meter, including the measuring pipe section 102 and the threaded section 101 used for connection at both ends of the measuring pipe section. The angle between the projections of the installation plane of the water meter is α, α=arctan(D / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com