Detection device for diaphragm type clamping cylinder production

A clamping cylinder and detection device technology, which is applied in the field of clamping cylinders, can solve the problems of inconvenient operation and low quality inspection efficiency, and achieve the effects of improved work efficiency, fast speed and shortened time

Inactive Publication Date: 2022-06-21

常州荣玖机械有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003]The purpose of this invention is to make the staff do not need to perform complex operations during the detection process through the mutual cooperation of the test frame, the movable plate and the pressure sensor on the movable plate, and through The drive shaft drives the reciprocating lead screw to rotate, so that the telescopic hose can guide the air into the pressurized box and then transport it to the inside of the diaphragm, which will not affect the smooth operation of the diaphragm quality inspection on the clamping cylinder body due to the effect of air pressure difference , through the interfitting of the rotating gear and the driving gear, the driving gear, the cleaning wheel and the cleaning shaft are mutually transmitted through the transmission belt, so that the cleaning wheel can clean the dirt on the outside of the cylinder, improve the quality inspection efficiency, and solve the problem of clamping the cylinder During the quality inspection process, it is inconvenient for non-professionals to operate, the air pressure difference inside and outside the diaphragm affects the smooth operation of the diaphragm quality inspection, and the surface of the clamping cylinder is dirty, resulting in low quality inspection efficiency. Production testing device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

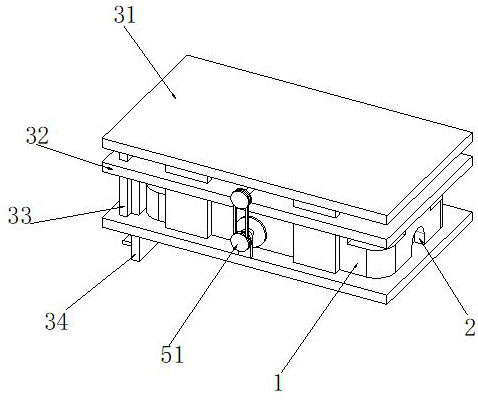

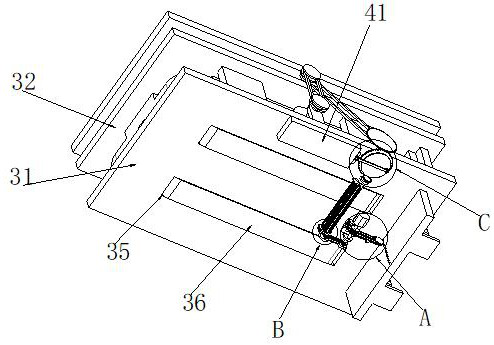

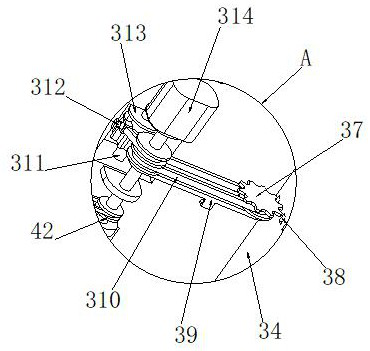

The invention relates to a clamping air cylinder technology, in particular to a detection device for diaphragm type clamping air cylinder production, which is used for solving the problems that non-professionals are inconvenient to operate in the quality inspection process of a clamping air cylinder, the quality inspection operation of a diaphragm is smoothly carried out due to the internal and external air pressure difference of the diaphragm, and the quality inspection efficiency is low due to smudginess of the surface of the clamping air cylinder. Through mutual cooperation of the test frame, the movable plate and a pressure sensor on the movable plate, a worker does not need to perform complex operation in the detection process, a reciprocating lead screw is driven to rotate through a driving rotating shaft, a telescopic hose guides air into a pressurization box to be pressurized, and then the pressurized air is conveyed into a diaphragm; smooth quality inspection operation of a diaphragm on a clamping air cylinder body cannot be affected by the effect of air pressure difference, through mutual embedding of a rotating gear and a driving gear and mutual transmission of the driving gear, a cleaning wheel and a cleaning rotating shaft through a transmission belt, the cleaning wheel cleans dirt on the outer side of the air cylinder, and the quality inspection efficiency is improved.

Description

technical field [0001] The invention relates to clamping cylinder technology, in particular to a detection device for the production of diaphragm clamping cylinders. Background technique [0002] A cylinder is a cylindrical hollow chamber in an engine containing a piston pushed by the pressure or expansion of the working fluid, a similar but non-cylindrical part in some special types of engines; In the prior art, there is no special equipment for detecting the diaphragm clamping cylinder, which makes the operation of the staff more complicated in the process of using the corresponding equipment to detect the diaphragm clamping cylinder, and it is easy for the staff to detect. Errors lead to inaccurate detection data, and some quality inspection equipment needs to be operated by professionals, and non-professional misuse may easily cause damage to quality inspection equipment and cylinders; when testing the diaphragm on the clamping cylinder body, external input is often use...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/36G01N3/04G01N3/02B08B1/04

CPCG01N3/36G01N3/04G01N3/02G01N2203/0005G01N2203/0017G01N2203/0019G01N2203/0411B08B1/32

Inventor 戎绍辉沈秀丽

Owner 常州荣玖机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com