Image sensor assembly, camera module and mobile device

An image sensor and component technology, applied in the field of image sensors, can solve the problems of camera module optical focus shift, affecting the function and service life of electronic components, etc., to reduce vibration, avoid optical focus shift, and enhance heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

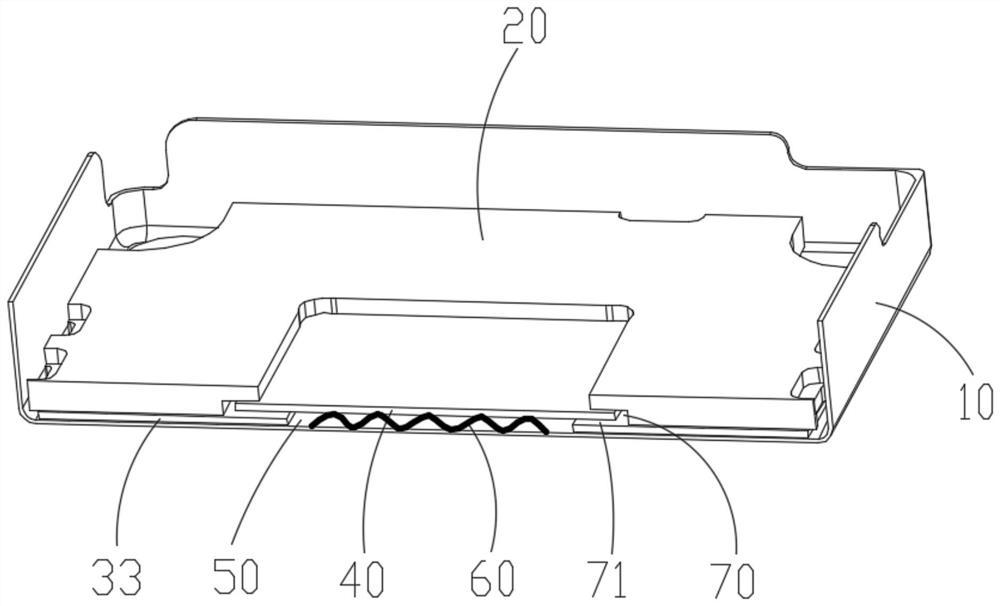

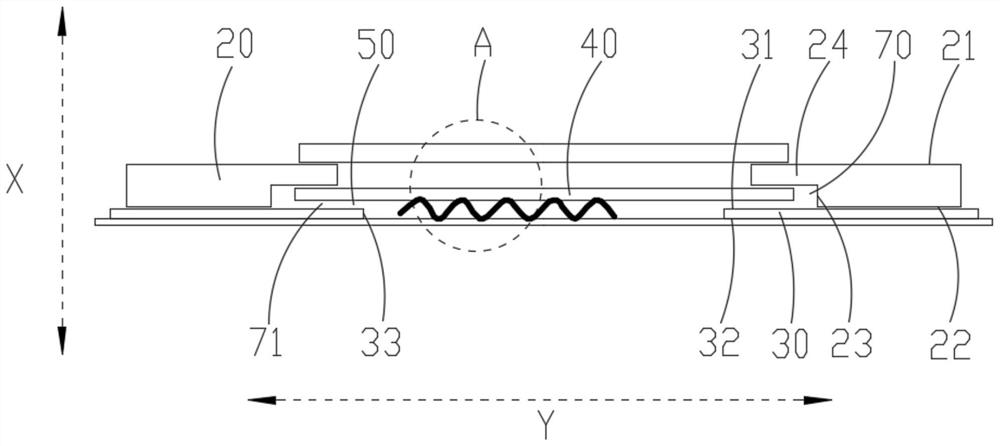

[0056] figure 1 A schematic structural diagram of an image sensor assembly provided in an embodiment of the present application, figure 2 for figure 1 Side view of the image sensor assembly shown.

[0057] like figure 1 and figure 2 As shown, this embodiment provides an image sensor assembly, including:

[0058] housing 10;

[0059] The base plate 20 is located in the housing 10 and includes an upper surface 21 and a lower surface 22 opposite to each other and a side surface 23 connected between the upper surface 21 and the lower surface 22, and the side surface 23 close to the upper surface 21 is convex on the side There is an installation part 24;

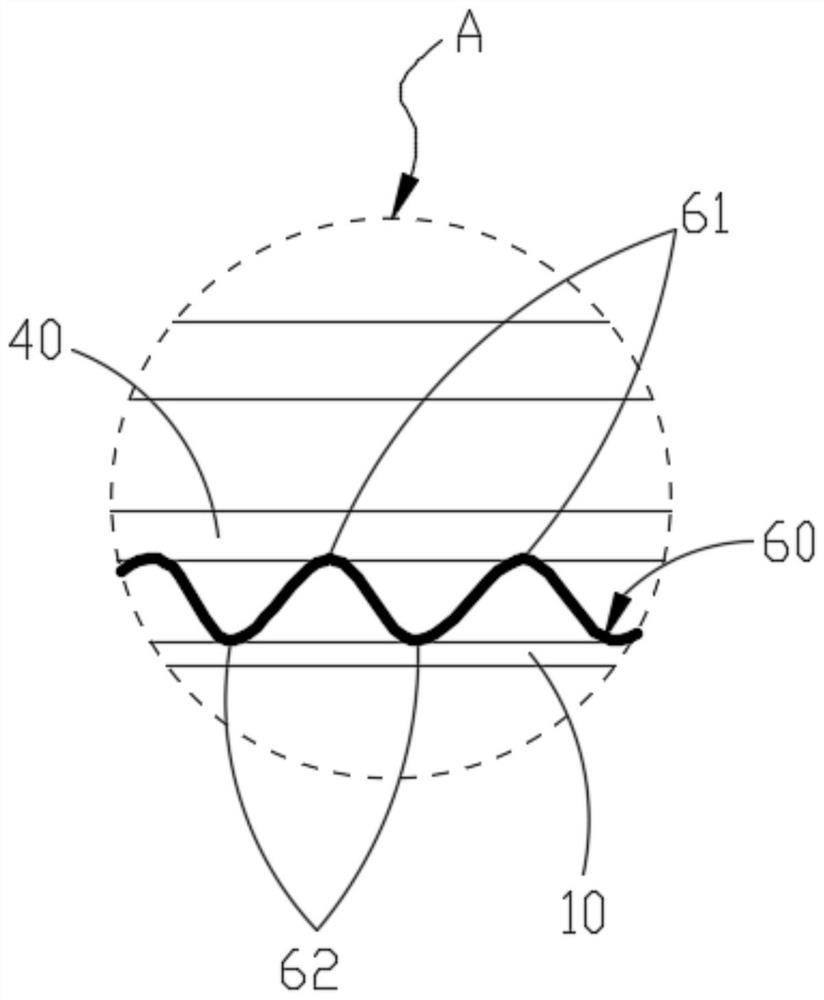

[0060] The flexible board 30 is located in the housing 10 and includes a first surface 31 and a second surface 32 opposite to each other, one end of the first surface 31 is connected with the lower surface 22 of the substrate 20 and the second surface 32 is connected with the housing 10 , the flexible board 30 is also pr...

Embodiment 2

[0086] like figure 1 and figure 2 As shown, this embodiment provides an image sensor assembly, including:

[0087] housing 10;

[0088] The base plate 20 is located in the housing 10 and includes an upper surface 21 and a lower surface 22 opposite to each other and a side surface 23 connected between the upper surface 21 and the lower surface 22, and the side surface 23 close to the upper surface 21 is convex on the side There is an installation part 24;

[0089] The flexible board 30 is located in the housing 10 and includes a first surface 31 and a second surface 32 opposite to each other, one end of the first surface 31 is connected with the lower surface 22 of the substrate 20 and the second surface 32 is connected with the housing 10 , the flexible board 30 is also provided with a through port 33;

[0090] The image sensor chip 40 is located in the casing 10 and is connected to one surface of the mounting portion 24 close to the lower surface 22 of the substrate 20 a...

Embodiment 3

[0113] like figure 1 and figure 2 As shown, this embodiment provides an image sensor assembly, including:

[0114] housing 10;

[0115] The base plate 20 is located in the housing 10 and includes an upper surface 21 and a lower surface 22 opposite to each other and a side surface 23 connected between the upper surface 21 and the lower surface 22, and the side surface 23 close to the upper surface 21 is convex on the side There is an installation part 24;

[0116] The flexible board 30 is located in the housing 10 and includes a first surface 31 and a second surface 32 opposite to each other, one end of the first surface 31 is connected with the lower surface 22 of the substrate 20 and the second surface 32 is connected with the housing 10 , the flexible board 30 is also provided with a through port 33;

[0117] The image sensor chip 40 is located in the casing 10 and is connected to one surface of the mounting portion 24 close to the lower surface 22 of the substrate 20 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com