Solenoid valve mechanism and high-pressure fuel supply pump

A solenoid valve and magnetic core technology, applied in the direction of fuel injection pump, fuel injection device, valve device, etc., can solve the problem that the valve core cannot contact the valve seat and the valve cannot be closed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

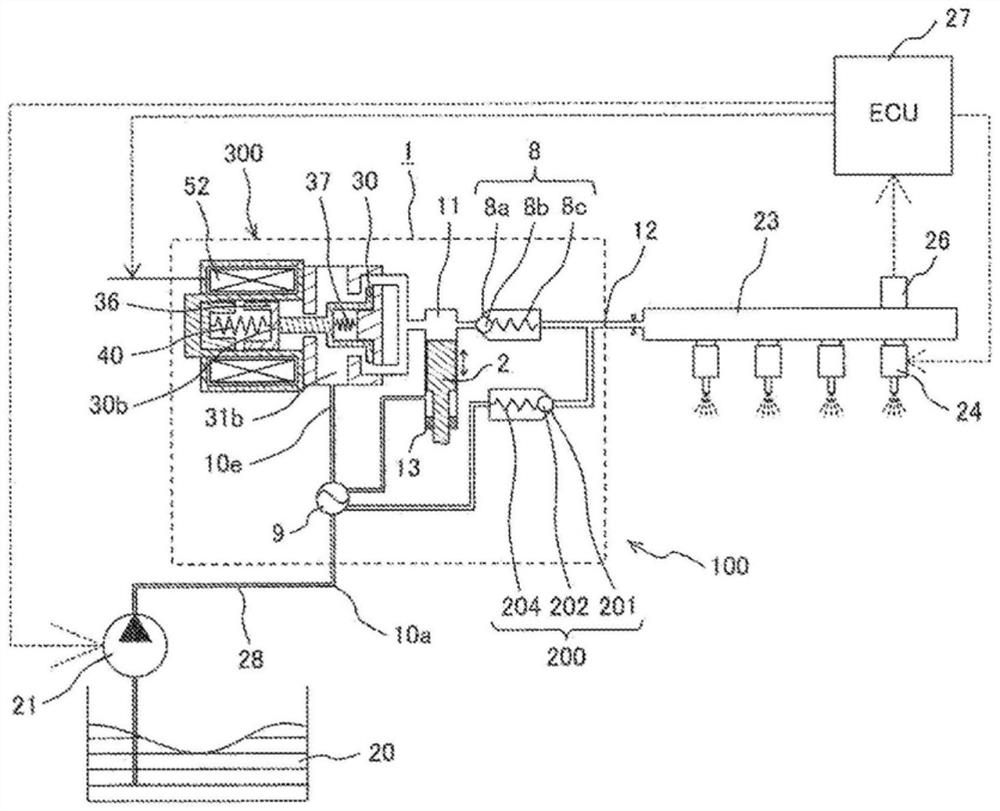

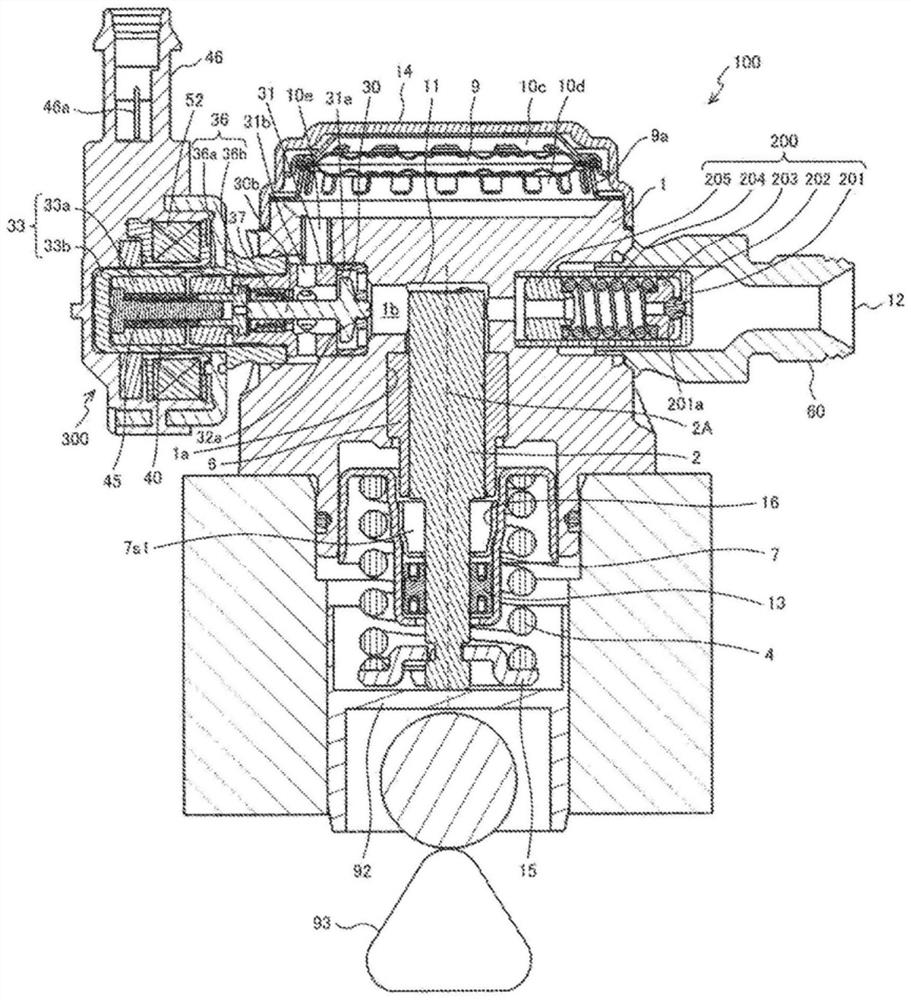

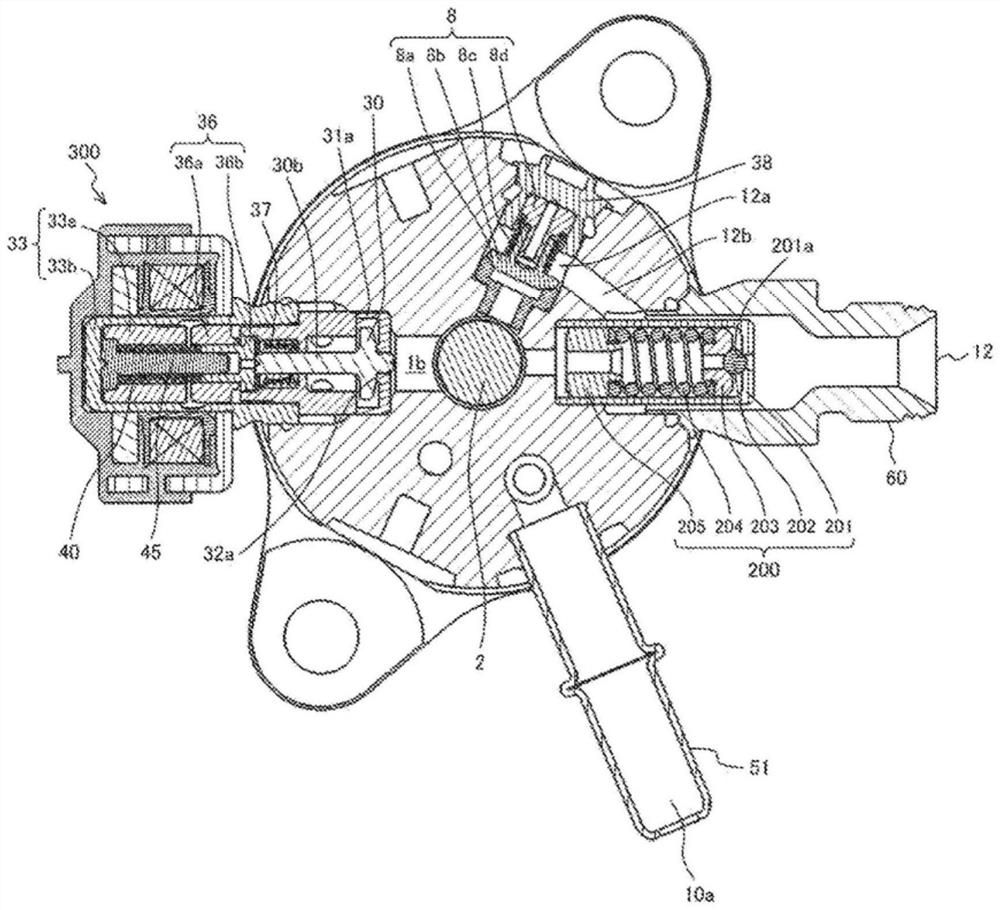

[0030] Buffer chambers 10b, 10c communicating with the low-pressure fuel suction port 10a and the low-pressure fuel suction passage 10b are formed on the upper and lower surfaces of the pressure pulsation reducing mechanism 9 . In addition, although not shown in the drawings, a passage for communicating the upper side and the lower side of the pressure pulsation reducing mechanism 9 is formed in the holding member 9a.

[0031] like figure 2 As shown, the fuel passing through the buffer chambers 10b, 10c then reaches the suction passage 31b of the solenoid valve mechanism 300 through the low-pressure fuel suction passage 10e formed in the pump body 1 extending in the vertical direction. In addition, a suction passage 31b is formed in the up-down direction in the suction valve seat member 31 forming the suction valve seat 31a.

[0032] like figure 2 As shown, the terminal 46a is integrally molded with the connector 46, and the unmolded end is configured so that it can be con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com